What is Medical Tube Cutting Machine - Global Market?

Medical tube cutting machines are specialized equipment used in the healthcare industry to precisely cut medical tubing into desired lengths. These machines are essential in the production of various medical devices, such as catheters, IV sets, and other tubing-based products. The global market for medical tube cutting machines is driven by the increasing demand for medical devices and the need for high precision and efficiency in manufacturing processes. These machines come in various types, including automatic and semi-automatic models, and are designed to handle different materials like PVC, silicone, and TPE. The market is characterized by technological advancements that enhance the accuracy and speed of cutting operations, thereby improving productivity. Additionally, the growing focus on healthcare infrastructure development and the rising prevalence of chronic diseases are contributing to the expansion of this market. Manufacturers are continuously innovating to meet the stringent regulatory standards and the specific requirements of medical device manufacturers. As a result, the medical tube cutting machine market is poised for significant growth, driven by the increasing adoption of advanced manufacturing technologies and the expanding global healthcare sector.

Electric, Pneumatic in the Medical Tube Cutting Machine - Global Market:

Electric and pneumatic medical tube cutting machines are two prominent types of equipment used in the global market for cutting medical tubing. Electric tube cutting machines are powered by electricity and are known for their precision and efficiency. They are equipped with advanced features such as digital controls, automated feeding systems, and programmable settings, which allow for high accuracy in cutting operations. These machines are ideal for high-volume production environments where consistency and speed are crucial. Electric machines are also favored for their low maintenance requirements and ability to handle a wide range of tubing materials, including PVC, silicone, and TPE. On the other hand, pneumatic tube cutting machines operate using compressed air and are known for their simplicity and reliability. They are often used in settings where electricity may not be readily available or where a more straightforward, cost-effective solution is needed. Pneumatic machines are typically more compact and portable than their electric counterparts, making them suitable for smaller production facilities or on-site applications. They are also valued for their ability to deliver consistent cutting performance with minimal operator intervention. Both electric and pneumatic tube cutting machines play a vital role in the medical device manufacturing process, offering unique advantages that cater to different production needs. The choice between electric and pneumatic machines often depends on factors such as production volume, material type, and specific application requirements. As the demand for medical devices continues to grow, manufacturers are increasingly investing in advanced tube cutting technologies to enhance their production capabilities and meet the evolving needs of the healthcare industry. This trend is expected to drive further innovation and development in the global market for medical tube cutting machines, with a focus on improving efficiency, precision, and versatility.

Silica Gel, Heat Shrink Tubing, PVC, TPE, Emulsion, Others in the Medical Tube Cutting Machine - Global Market:

Medical tube cutting machines are utilized in various applications, including silica gel, heat shrink tubing, PVC, TPE, emulsion, and other materials. In the case of silica gel, these machines are used to cut tubing that is often employed in moisture control and drug delivery systems. The precision of the cutting process is crucial to ensure the effectiveness and safety of the final product. For heat shrink tubing, medical tube cutting machines are essential in producing tubing that can be used for insulation and protection of medical devices. The ability to cut heat shrink tubing to precise lengths ensures that it fits perfectly over the components it is meant to protect. PVC is another common material used in medical tubing, and cutting machines are vital in producing PVC tubing for applications such as IV lines and catheters. The machines must be capable of handling the flexibility and durability of PVC to produce high-quality tubing. TPE, or thermoplastic elastomer, is used in medical tubing for its flexibility and resistance to chemicals. Medical tube cutting machines must be able to cut TPE tubing accurately to maintain its properties and ensure it meets the necessary standards for medical use. Emulsion-based tubing is used in various medical applications, and cutting machines are required to handle the unique properties of emulsion materials. The machines must be able to cut the tubing without compromising its integrity or performance. In addition to these materials, medical tube cutting machines are also used for other specialized tubing applications, where precision and consistency are paramount. The versatility of these machines allows them to be adapted for different materials and applications, making them an essential tool in the medical device manufacturing process. As the demand for high-quality medical tubing continues to rise, the role of medical tube cutting machines in ensuring the production of reliable and effective medical devices becomes increasingly important.

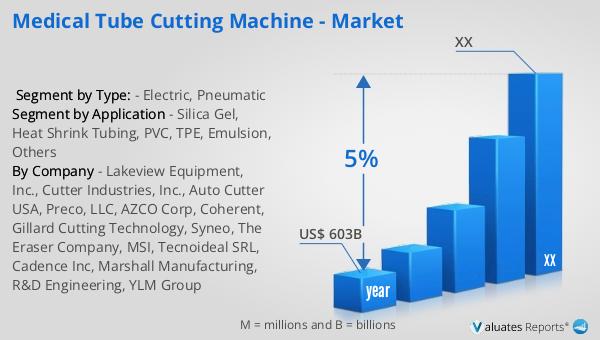

Medical Tube Cutting Machine - Global Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including the increasing prevalence of chronic diseases, advancements in medical technology, and the expanding healthcare infrastructure worldwide. The demand for innovative and efficient medical devices is on the rise, as healthcare providers seek to improve patient outcomes and streamline operations. Additionally, the aging population and the growing awareness of health and wellness are contributing to the increased demand for medical devices. As a result, manufacturers are focusing on developing cutting-edge products that meet the evolving needs of the healthcare industry. The medical tube cutting machine market is an integral part of this broader medical device market, as it provides the necessary equipment for producing high-quality medical tubing. The precision and efficiency offered by these machines are essential for meeting the stringent regulatory standards and ensuring the safety and effectiveness of medical devices. As the global market for medical devices continues to expand, the demand for advanced tube cutting technologies is expected to grow, driving further innovation and development in this sector. Manufacturers are likely to invest in research and development to enhance the capabilities of medical tube cutting machines, ensuring they can meet the diverse needs of the healthcare industry and support the production of a wide range of medical devices.

| Report Metric | Details |

| Report Name | Medical Tube Cutting Machine - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Lakeview Equipment, Inc., Cutter Industries, Inc., Auto Cutter USA, Preco, LLC, AZCO Corp, Coherent, Gillard Cutting Technology, Syneo, The Eraser Company, MSI, Tecnoideal SRL, Cadence Inc, Marshall Manufacturing, R&D Engineering, YLM Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |