What is High Speed Spindle - Global Market?

High-speed spindles are essential components in various industrial applications, known for their ability to rotate at extremely high speeds, often exceeding 10,000 RPM. These spindles are crucial in industries where precision, speed, and efficiency are paramount. The global market for high-speed spindles is driven by the increasing demand for high-precision machining and manufacturing processes across various sectors. These spindles are used in CNC machines, milling machines, and other equipment that require high-speed rotation to achieve fine finishes and precise cuts. The market is characterized by technological advancements that enhance spindle performance, such as improved materials, better cooling systems, and advanced control systems. The demand for high-speed spindles is also fueled by the growing need for automation in manufacturing, which requires reliable and efficient spindle systems. As industries continue to evolve, the high-speed spindle market is expected to grow, driven by innovations and the need for more efficient production processes. The market is also influenced by the increasing adoption of electric vehicles and the aerospace industry's demand for lightweight and durable components, which require high-speed machining capabilities. Overall, the high-speed spindle market is poised for significant growth as industries seek to improve productivity and precision in their operations.

Rolling Spindles, Air Bearing Spindles, Liquid Journal Spindles in the High Speed Spindle - Global Market:

Rolling spindles, air bearing spindles, and liquid journal spindles are three types of high-speed spindles that cater to different industrial needs. Rolling spindles are known for their robustness and ability to handle heavy loads, making them ideal for applications that require high torque and power. These spindles use rolling elements, such as ball or roller bearings, to support the rotating shaft, providing stability and reducing friction. This design allows for high-speed operation while maintaining precision and durability. Rolling spindles are commonly used in heavy-duty machining applications, where the ability to handle large forces is crucial. On the other hand, air bearing spindles are designed for applications that require ultra-high precision and minimal friction. These spindles use a thin film of compressed air to support the rotating shaft, eliminating contact between moving parts and reducing wear. This design allows for extremely high speeds and precision, making air bearing spindles ideal for applications in the semiconductor and electronics industries, where even the slightest vibration can affect the quality of the final product. Liquid journal spindles, meanwhile, use a thin film of liquid, typically oil, to support the rotating shaft. This design provides excellent damping properties, reducing vibrations and noise during operation. Liquid journal spindles are often used in applications that require smooth and quiet operation, such as in the aerospace and automotive industries. Each type of spindle offers unique advantages, and the choice of spindle depends on the specific requirements of the application, such as speed, precision, load capacity, and environmental conditions. As industries continue to demand higher precision and efficiency, the development and adoption of advanced spindle technologies are expected to grow, driving innovation and competition in the global high-speed spindle market.

PCB Industry, Consumer Electronic, Machinery Manufacturing, Automotive and Aerospace, Others in the High Speed Spindle - Global Market:

High-speed spindles play a crucial role in various industries, including the PCB industry, consumer electronics, machinery manufacturing, automotive and aerospace, and others. In the PCB industry, high-speed spindles are used in drilling and routing machines to create precise holes and cuts in printed circuit boards. The high rotational speeds of these spindles allow for clean and accurate machining, which is essential for the production of high-quality PCBs. In the consumer electronics sector, high-speed spindles are used in the manufacturing of components such as smartphone casings, camera lenses, and other precision parts. The ability to achieve fine finishes and intricate details is critical in this industry, where product aesthetics and functionality are paramount. In machinery manufacturing, high-speed spindles are used in CNC machines and other equipment to produce parts with high precision and efficiency. These spindles enable manufacturers to achieve tight tolerances and high-quality finishes, which are essential in producing components for various machinery. In the automotive and aerospace industries, high-speed spindles are used in the machining of lightweight and durable materials, such as aluminum and composites. These materials require high-speed machining to achieve the desired properties and performance. High-speed spindles allow for efficient and precise machining, which is crucial in producing components that meet the stringent requirements of these industries. Other industries that benefit from high-speed spindles include medical device manufacturing, where precision and cleanliness are critical, and the mold and die industry, where intricate details and fine finishes are required. Overall, high-speed spindles are indispensable in industries that demand high precision, efficiency, and quality in their manufacturing processes.

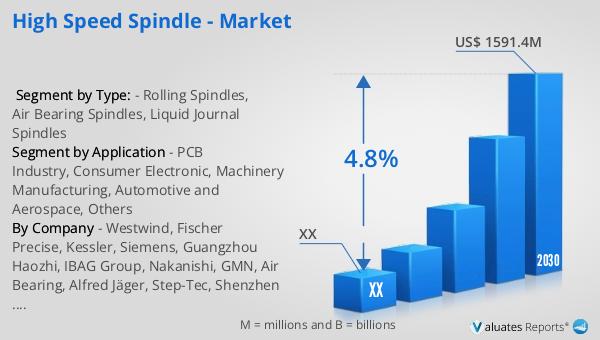

High Speed Spindle - Global Market Outlook:

The global market for high-speed spindles was valued at approximately $1,166 million in 2023. This market is projected to grow significantly, reaching an estimated size of $1,591.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. The increasing demand for high-speed spindles is driven by the need for precision and efficiency in various industries, including automotive, aerospace, electronics, and manufacturing. As these industries continue to evolve and adopt new technologies, the demand for high-speed spindles is expected to rise. The market is also influenced by the growing trend towards automation and the need for reliable and efficient spindle systems in automated manufacturing processes. Additionally, the increasing adoption of electric vehicles and the aerospace industry's demand for lightweight and durable components are expected to drive the demand for high-speed spindles. As a result, manufacturers are investing in research and development to create advanced spindle technologies that meet the evolving needs of these industries. Overall, the high-speed spindle market is poised for significant growth, driven by technological advancements and the increasing demand for precision and efficiency in manufacturing processes.

| Report Metric | Details |

| Report Name | High Speed Spindle - Market |

| Forecasted market size in 2030 | US$ 1591.4 million |

| CAGR | 4.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Westwind, Fischer Precise, Kessler, Siemens, Guangzhou Haozhi, IBAG Group, Nakanishi, GMN, Air Bearing, Alfred Jäger, Step-Tec, Shenzhen Sufeng, Posa, KLKJ, Heinz Fiege GmbH, SycoTec |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |