What is DC Vacuum Sputter Equipment - Global Market?

DC Vacuum Sputter Equipment is a specialized tool used in the process of thin-film deposition, which is crucial in various high-tech industries. This equipment operates under a vacuum environment and utilizes a direct current (DC) power source to sputter, or eject, material from a target onto a substrate, forming a thin film. The global market for DC Vacuum Sputter Equipment is driven by its extensive applications in sectors such as electronics, automotive, and general machinery. As industries continue to demand more advanced and efficient technologies, the need for precise and reliable thin-film deposition methods like sputtering grows. This equipment is essential for manufacturing components that require specific material properties, such as semiconductors, solar panels, and optical devices. The market is characterized by continuous innovation and development, aiming to enhance the efficiency, precision, and cost-effectiveness of sputtering processes. As a result, companies in this market are investing heavily in research and development to meet the evolving needs of their customers and to maintain a competitive edge. The global market for DC Vacuum Sputter Equipment is poised for growth, driven by technological advancements and increasing demand across various industries.

Single Room, Double Room, Multi-Room in the DC Vacuum Sputter Equipment - Global Market:

In the context of DC Vacuum Sputter Equipment, the terms Single Room, Double Room, and Multi-Room refer to the configurations of the equipment used in the sputtering process. A Single Room configuration typically involves a single chamber where the entire sputtering process takes place. This setup is often used for simpler applications or smaller-scale production, where the requirements for film uniformity and deposition rate are not as stringent. Single Room systems are generally more cost-effective and easier to maintain, making them suitable for research and development purposes or for small to medium-sized enterprises that do not require high-volume production. On the other hand, Double Room configurations consist of two interconnected chambers. This setup allows for more complex processes, such as sequential deposition of different materials or the integration of additional processing steps like pre-cleaning or post-deposition annealing. Double Room systems offer greater flexibility and control over the sputtering process, enabling manufacturers to achieve higher quality films with improved properties. These systems are often used in industries where precision and performance are critical, such as in the production of advanced electronic components or high-performance coatings. Multi-Room configurations, as the name suggests, involve multiple chambers that can be used for different stages of the sputtering process. This setup is ideal for large-scale production environments where high throughput and efficiency are paramount. Multi-Room systems allow for continuous operation, as substrates can be loaded and unloaded in different chambers without interrupting the sputtering process. This configuration is particularly beneficial for industries that require mass production of thin films, such as the solar panel or display manufacturing sectors. The ability to perform multiple processes simultaneously in separate chambers also enhances the overall quality and consistency of the deposited films. In summary, the choice between Single Room, Double Room, and Multi-Room configurations depends on the specific requirements of the application, including the desired film properties, production volume, and budget constraints. Each configuration offers distinct advantages and challenges, and manufacturers must carefully consider these factors when selecting the appropriate DC Vacuum Sputter Equipment for their needs.

Automotive, General Machinery, Electronics, LED, Others in the DC Vacuum Sputter Equipment - Global Market:

DC Vacuum Sputter Equipment finds extensive usage across various industries, including automotive, general machinery, electronics, LED, and others, due to its ability to deposit thin films with high precision and uniformity. In the automotive industry, this equipment is used to apply coatings that enhance the durability and performance of components such as engine parts, sensors, and electronic control units. These coatings can improve wear resistance, reduce friction, and protect against corrosion, thereby extending the lifespan of automotive components and improving overall vehicle performance. In the general machinery sector, DC Vacuum Sputter Equipment is employed to deposit protective and functional coatings on machine parts and tools. These coatings can enhance the hardness, thermal stability, and chemical resistance of the components, leading to improved efficiency and reduced maintenance costs. The electronics industry is one of the largest consumers of DC Vacuum Sputter Equipment, as it is essential for the production of semiconductors, integrated circuits, and other electronic components. The ability to deposit thin films with precise control over thickness and composition is crucial for the performance and reliability of electronic devices. In the LED industry, sputtering is used to deposit reflective and conductive coatings on LED chips and substrates, which can enhance light output and energy efficiency. Other industries that utilize DC Vacuum Sputter Equipment include the aerospace, medical, and optical sectors, where thin-film coatings are used to improve the performance and functionality of various components and devices. The versatility and precision of DC Vacuum Sputter Equipment make it an indispensable tool for manufacturers seeking to enhance the quality and performance of their products across a wide range of applications.

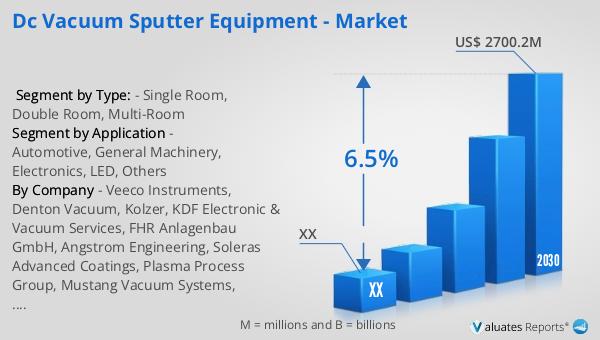

DC Vacuum Sputter Equipment - Global Market Outlook:

The global market for DC Vacuum Sputter Equipment was valued at approximately $1,871.3 million in 2023, and it is projected to grow to a size of around $2,700.2 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. The North American segment of this market was also valued at a significant amount in 2023, with expectations of continued growth through 2030. The increasing demand for advanced thin-film deposition technologies across various industries is a key driver of this market growth. As industries such as electronics, automotive, and renewable energy continue to expand and innovate, the need for precise and efficient sputtering equipment becomes more critical. Companies operating in this market are focusing on developing advanced technologies and expanding their product portfolios to meet the evolving needs of their customers. The market is characterized by intense competition, with key players investing heavily in research and development to gain a competitive edge. As a result, the DC Vacuum Sputter Equipment market is poised for significant growth, driven by technological advancements and increasing demand across various industries.

| Report Metric | Details |

| Report Name | DC Vacuum Sputter Equipment - Market |

| Forecasted market size in 2030 | US$ 2700.2 million |

| CAGR | 6.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Veeco Instruments, Denton Vacuum, Kolzer, KDF Electronic & Vacuum Services, FHR Anlagenbau GmbH, Angstrom Engineering, Soleras Advanced Coatings, Plasma Process Group, Mustang Vacuum Systems, Kenosistec, Scientific Vacuum Systems, AJA International, Shincron |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |