What is Global VIGA (Vacuum Induction Inert Gas Atomization) Equipment Market?

The Global VIGA (Vacuum Induction Inert Gas Atomization) Equipment Market is a specialized sector within the broader field of materials processing and manufacturing. This market revolves around the production and sale of equipment used to create high-quality metal powders through a process known as Vacuum Induction Inert Gas Atomization (VIGA). In this process, metals are melted under vacuum conditions and then atomized into fine powders using an inert gas. These powders are crucial for various applications, including additive manufacturing, powder metallurgy, and advanced material development. The VIGA process is highly valued for its ability to produce powders with excellent purity, uniform particle size distribution, and superior flow characteristics. This makes it an essential technology for industries that require high-performance materials, such as aerospace, automotive, and medical device manufacturing. As industries continue to demand more advanced materials, the Global VIGA Equipment Market is poised for growth, driven by technological advancements and increasing applications of metal powders. The market's expansion is also supported by the rising interest in sustainable manufacturing practices, as VIGA technology offers efficient and environmentally friendly production methods.

Small VIGA Systems (<50 kg), Medium VIGA Systems (50~250 kg), Large VIGA Systems (≥250 kg) in the Global VIGA (Vacuum Induction Inert Gas Atomization) Equipment Market:

In the Global VIGA Equipment Market, systems are categorized based on their capacity to process metal, which is measured in kilograms. Small VIGA Systems, with a capacity of less than 50 kg, are typically used for specialized applications where smaller quantities of metal powder are required. These systems are ideal for research and development purposes, allowing scientists and engineers to experiment with new alloys and compositions without the need for large-scale production. They are also used by niche manufacturers who produce limited runs of specialized products. Medium VIGA Systems, with a capacity ranging from 50 to 250 kg, serve a broader range of applications. These systems strike a balance between production volume and flexibility, making them suitable for small to medium-sized enterprises that require moderate quantities of metal powder. They are often used in industries such as automotive and consumer electronics, where there is a need for high-quality powders but not necessarily in large volumes. Large VIGA Systems, with a capacity of 250 kg or more, are designed for high-volume production. These systems are used by major manufacturers in industries such as aerospace and defense, where large quantities of metal powder are needed to meet production demands. The ability to produce large volumes of powder efficiently makes these systems a critical component of the supply chain for high-performance materials. Each category of VIGA system plays a vital role in the market, catering to different needs and applications. The choice of system depends on factors such as production volume, material requirements, and budget constraints. As the demand for metal powders continues to grow, manufacturers are investing in VIGA systems that best meet their specific needs, driving innovation and competition within the market.

Metal Powder Manufacturer, Research Institutes in the Global VIGA (Vacuum Induction Inert Gas Atomization) Equipment Market:

The Global VIGA Equipment Market finds significant usage in various sectors, particularly among metal powder manufacturers and research institutes. Metal powder manufacturers rely heavily on VIGA technology to produce high-quality powders that meet the stringent requirements of their clients. The ability to produce powders with consistent particle size and high purity is crucial for applications such as additive manufacturing and powder metallurgy. VIGA systems enable manufacturers to achieve these standards, ensuring that their products are competitive in the global market. The flexibility of VIGA technology also allows manufacturers to produce a wide range of alloys, catering to diverse industry needs. Research institutes, on the other hand, utilize VIGA equipment to explore new materials and processes. The ability to produce small batches of metal powder with precise control over composition and particle size is invaluable for research and development. Institutes use VIGA systems to study the properties of new alloys, develop innovative manufacturing techniques, and contribute to advancements in material science. The insights gained from this research often lead to breakthroughs that drive the industry forward. Both metal powder manufacturers and research institutes benefit from the versatility and precision of VIGA technology, making it a cornerstone of modern materials processing. As the demand for advanced materials continues to rise, the role of VIGA equipment in these sectors is expected to grow, supporting innovation and development across various industries.

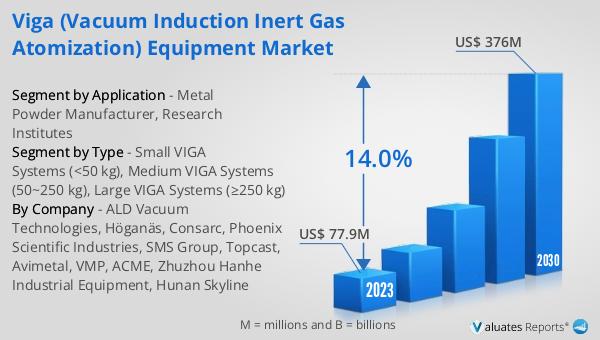

Global VIGA (Vacuum Induction Inert Gas Atomization) Equipment Market Outlook:

The market outlook for the Global VIGA Equipment Market indicates a promising future. In 2023, the market was valued at approximately US$ 77.9 million. By 2030, it is expected to reach around US$ 376 million, reflecting a compound annual growth rate (CAGR) of 14.0% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality metal powders across various industries, including aerospace, automotive, and medical devices. The ability of VIGA technology to produce powders with superior properties makes it an attractive option for manufacturers looking to enhance their product offerings. Additionally, the growing interest in sustainable manufacturing practices is contributing to the market's expansion, as VIGA systems offer efficient and environmentally friendly production methods. As industries continue to evolve and demand more advanced materials, the Global VIGA Equipment Market is well-positioned to capitalize on these trends, providing innovative solutions to meet the needs of modern manufacturing.

| Report Metric | Details |

| Report Name | VIGA (Vacuum Induction Inert Gas Atomization) Equipment Market |

| Accounted market size in 2023 | US$ 77.9 million |

| Forecasted market size in 2030 | US$ 376 million |

| CAGR | 14.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ALD Vacuum Technologies, Höganäs, Consarc, Phoenix Scientific Industries, SMS Group, Topcast, Avimetal, VMP, ACME, Zhuzhou Hanhe Industrial Equipment, Hunan Skyline |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |