What is Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market?

The Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market is a specialized sector within the broader materials and manufacturing industry. VIGA technology is used to produce high-quality metal powders by melting metals in a vacuum and then atomizing them using inert gas. This process ensures that the metal powders are free from contaminants and have a uniform particle size, which is crucial for applications in advanced manufacturing, aerospace, medical devices, and other high-tech industries. The market for VIGA systems is driven by the increasing demand for high-performance materials and the growing adoption of additive manufacturing technologies. Companies in this market are continuously innovating to improve the efficiency and capabilities of VIGA systems, making them more accessible and cost-effective for a wider range of applications. The global VIGA market is characterized by a mix of established players and new entrants, all competing to offer the best solutions to meet the evolving needs of their customers.

Small VIGA Systems (<50 kg), Medium VIGA Systems (50~250 kg), Large VIGA Systems (≥250 kg) in the Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market:

Small VIGA Systems, which have a capacity of less than 50 kg, are typically used for research and development purposes, as well as for the production of small batches of specialized metal powders. These systems are highly versatile and can be used to produce a wide range of metal powders, including those made from rare and expensive materials. Because of their smaller size, they are easier to install and operate, making them ideal for use in academic and industrial research settings. Medium VIGA Systems, with capacities ranging from 50 to 250 kg, are designed for medium-scale production. These systems are often used by companies that need to produce larger quantities of metal powders but do not require the full capacity of a large-scale system. Medium VIGA Systems offer a good balance between production capacity and operational flexibility, making them suitable for a wide range of applications. Large VIGA Systems, which have capacities of 250 kg or more, are used for large-scale production of metal powders. These systems are typically used by companies that need to produce large quantities of metal powders for use in high-volume manufacturing processes. Large VIGA Systems are designed to be highly efficient and cost-effective, with advanced features that allow for precise control over the melting and atomization processes. Despite their larger size, these systems are designed to be easy to operate and maintain, ensuring that they can be used to produce high-quality metal powders consistently and reliably. The choice between small, medium, and large VIGA systems depends on a variety of factors, including the specific needs of the user, the types of metal powders being produced, and the scale of production required. Each type of system has its own unique advantages and is suited to different applications, making it important for users to carefully consider their options before making a decision.

Metal Powder Manufacturer, Research Institutes in the Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market:

The Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market finds significant usage in various sectors, particularly among metal powder manufacturers and research institutes. Metal powder manufacturers utilize VIGA systems to produce high-quality metal powders that are essential for various advanced manufacturing processes, including additive manufacturing, also known as 3D printing. The ability to produce metal powders with uniform particle size and high purity is crucial for ensuring the quality and performance of the final products. VIGA technology allows manufacturers to produce a wide range of metal powders, including those made from rare and expensive materials, which are used in industries such as aerospace, automotive, and medical devices. Research institutes, on the other hand, use VIGA systems for a variety of purposes, including the development of new materials and the study of the properties of different metal powders. The versatility and precision of VIGA systems make them ideal for use in research settings, where scientists and engineers can experiment with different materials and processes to develop new and innovative solutions. The ability to produce small batches of specialized metal powders is particularly valuable for research institutes, as it allows them to conduct experiments and tests without the need for large-scale production. In addition to their use in metal powder manufacturing and research, VIGA systems are also used in other applications, such as the production of metal coatings and the recycling of metal scrap. The ability to produce high-quality metal powders from recycled materials is an important advantage of VIGA technology, as it helps to reduce waste and promote sustainability in the manufacturing industry. Overall, the Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market plays a crucial role in the production of high-quality metal powders and the development of new materials and technologies, making it an essential component of the modern manufacturing landscape.

Global Vacuum Induction Melting Inert Gas Atomization (VIGA) Market Outlook:

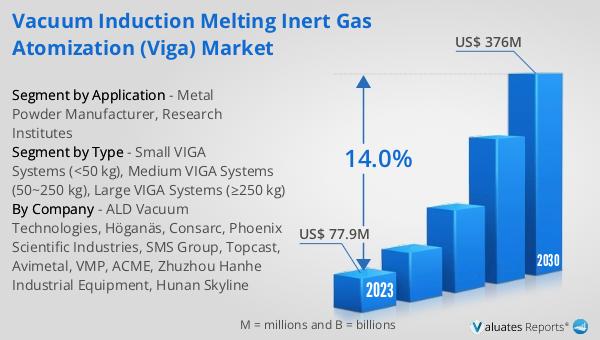

The global Vacuum Induction Melting Inert Gas Atomization (VIGA) market was valued at US$ 77.9 million in 2023 and is anticipated to reach US$ 376 million by 2030, witnessing a CAGR of 14.0% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing demand for high-quality metal powders in various industries, including aerospace, automotive, and medical devices. The adoption of additive manufacturing technologies, which rely heavily on high-quality metal powders, is also contributing to the growth of the VIGA market. Companies in this market are continuously innovating to improve the efficiency and capabilities of VIGA systems, making them more accessible and cost-effective for a wider range of applications. The market is characterized by a mix of established players and new entrants, all competing to offer the best solutions to meet the evolving needs of their customers. As the demand for high-performance materials continues to grow, the VIGA market is expected to see continued growth and development in the coming years.

| Report Metric | Details |

| Report Name | Vacuum Induction Melting Inert Gas Atomization (VIGA) Market |

| Accounted market size in 2023 | US$ 77.9 million |

| Forecasted market size in 2030 | US$ 376 million |

| CAGR | 14.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ALD Vacuum Technologies, Höganäs, Consarc, Phoenix Scientific Industries, SMS Group, Topcast, Avimetal, VMP, ACME, Zhuzhou Hanhe Industrial Equipment, Hunan Skyline |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |