What is Eco Vacuum Furnaces - Global Market?

Eco vacuum furnaces are specialized equipment used in various industries to perform heat treatment processes under vacuum conditions. These furnaces are designed to minimize environmental impact by reducing energy consumption and emissions, making them an attractive choice for companies aiming to adopt more sustainable manufacturing practices. The global market for eco vacuum furnaces is driven by the increasing demand for energy-efficient and environmentally friendly industrial solutions. These furnaces are used in applications such as annealing, brazing, sintering, and hardening of metals and alloys. The market is characterized by technological advancements that enhance the efficiency and performance of these furnaces, as well as by the growing awareness of the benefits of vacuum technology in improving product quality and reducing production costs. As industries continue to prioritize sustainability, the demand for eco vacuum furnaces is expected to grow, supported by government regulations and incentives promoting green technologies. The market is also influenced by the expansion of industries such as aerospace, automotive, and electronics, which require advanced heat treatment solutions to meet stringent quality standards. Overall, the eco vacuum furnaces market represents a significant opportunity for manufacturers and suppliers to capitalize on the trend towards sustainable industrial practices.

Single Chamber Furnace, Double Chamber Furnace, Multi-chamber Furnace in the Eco Vacuum Furnaces - Global Market:

Eco vacuum furnaces come in various configurations, including single chamber, double chamber, and multi-chamber designs, each offering unique advantages for different industrial applications. Single chamber furnaces are the most basic type, consisting of a single enclosed space where the entire heat treatment process takes place. These furnaces are ideal for small-scale operations or applications where simplicity and cost-effectiveness are priorities. They offer easy operation and maintenance, making them suitable for industries with limited technical expertise. However, single chamber furnaces may have limitations in terms of processing capacity and flexibility, as all stages of the heat treatment process occur in the same space, which can lead to cross-contamination or inefficiencies in certain applications. Double chamber furnaces, on the other hand, feature two separate chambers that allow for more complex heat treatment processes. One chamber is typically used for heating, while the other is used for cooling, enabling more precise control over the temperature and atmosphere conditions. This configuration reduces the risk of contamination and allows for faster processing times, as the cooling phase can occur independently of the heating phase. Double chamber furnaces are well-suited for medium to large-scale operations and are commonly used in industries such as aerospace and automotive, where high precision and quality are essential. Multi-chamber furnaces take this concept a step further by incorporating multiple chambers for different stages of the heat treatment process. This design offers the highest level of flexibility and efficiency, as each chamber can be optimized for specific tasks, such as preheating, heating, and cooling. Multi-chamber furnaces are ideal for large-scale industrial applications that require high throughput and stringent quality control. They are often used in the production of complex components and materials that demand precise thermal processing. The choice between single, double, and multi-chamber furnaces depends on factors such as the scale of operation, the complexity of the heat treatment process, and the specific requirements of the industry. As the global market for eco vacuum furnaces continues to grow, manufacturers are focusing on developing innovative designs and technologies to meet the diverse needs of their customers. This includes advancements in automation, control systems, and energy efficiency, which enhance the performance and sustainability of these furnaces. By offering a range of configurations, eco vacuum furnace manufacturers can cater to a wide array of industries and applications, supporting the transition towards more sustainable and efficient manufacturing practices.

Aerospace, Industrial, Commercial, Others in the Eco Vacuum Furnaces - Global Market:

Eco vacuum furnaces are utilized across various sectors, including aerospace, industrial, commercial, and others, each benefiting from the unique capabilities of these advanced heat treatment systems. In the aerospace industry, eco vacuum furnaces are essential for processing high-performance materials and components that must withstand extreme conditions. These furnaces enable precise control over temperature and atmosphere, ensuring the structural integrity and reliability of aerospace parts such as turbine blades, engine components, and structural elements. The use of eco vacuum furnaces in aerospace manufacturing supports the industry's commitment to safety, quality, and sustainability, as they reduce energy consumption and emissions compared to traditional heat treatment methods. In the industrial sector, eco vacuum furnaces are employed in a wide range of applications, from metalworking and tool manufacturing to electronics and semiconductor production. These furnaces offer the ability to perform complex heat treatment processes with high precision and repeatability, making them ideal for industries that require consistent quality and performance. The energy-efficient design of eco vacuum furnaces also helps industrial manufacturers reduce operational costs and minimize their environmental footprint, aligning with the growing emphasis on sustainable production practices. Commercial applications of eco vacuum furnaces include the production of consumer goods, such as household appliances, automotive parts, and electronic devices. These furnaces enable manufacturers to achieve high-quality finishes and durable products by providing controlled heat treatment processes that enhance material properties. The use of eco vacuum furnaces in commercial manufacturing supports the development of innovative products that meet consumer demands for performance and sustainability. Additionally, the versatility of these furnaces allows manufacturers to adapt to changing market trends and requirements, ensuring their competitiveness in a dynamic global market. Beyond aerospace, industrial, and commercial applications, eco vacuum furnaces are also used in other sectors, such as research and development, healthcare, and energy. In research and development, these furnaces facilitate the exploration of new materials and processes, enabling scientists and engineers to push the boundaries of innovation. In healthcare, eco vacuum furnaces are used to produce medical devices and implants that require precise thermal processing to ensure safety and efficacy. In the energy sector, these furnaces support the production of advanced materials for renewable energy technologies, such as solar panels and wind turbine components. The diverse applications of eco vacuum furnaces across different industries highlight their importance in supporting sustainable development and technological advancement. As the global market for eco vacuum furnaces continues to expand, manufacturers and users alike are recognizing the value of these systems in achieving their operational and environmental goals.

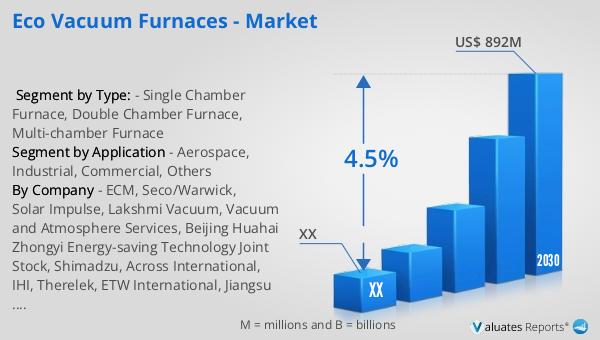

Eco Vacuum Furnaces - Global Market Outlook:

The global market for eco vacuum furnaces was valued at approximately $622 million in 2023, with projections indicating a growth to around $892 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing emphasis on sustainable manufacturing practices across various industries. As companies strive to reduce their environmental impact and comply with stringent regulations, the demand for energy-efficient and eco-friendly industrial solutions, such as eco vacuum furnaces, is on the rise. These furnaces offer significant advantages in terms of reducing energy consumption and emissions, making them an attractive option for manufacturers looking to enhance their sustainability credentials. The market is also influenced by technological advancements that improve the efficiency and performance of eco vacuum furnaces, further boosting their adoption in industries such as aerospace, automotive, and electronics. As the global focus on sustainability continues to intensify, the eco vacuum furnaces market is poised for steady growth, providing opportunities for manufacturers and suppliers to capitalize on this trend. By investing in innovative technologies and solutions, companies can position themselves as leaders in the transition towards more sustainable industrial practices, ultimately contributing to a greener and more sustainable future.

| Report Metric | Details |

| Report Name | Eco Vacuum Furnaces - Market |

| Forecasted market size in 2030 | US$ 892 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ECM, Seco/Warwick, Solar Impulse, Lakshmi Vacuum, Vacuum and Atmosphere Services, Beijing Huahai Zhongyi Energy-saving Technology Joint Stock, Shimadzu, Across International, IHI, Therelek, ETW International, Jiangsu HuaHong vacuum technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |