What is Vacuum Furnace in Heat Treatment Systems - Global Market?

A vacuum furnace is a specialized type of furnace used in heat treatment systems, designed to perform processes such as annealing, brazing, sintering, and hardening under a vacuum or controlled atmosphere. This technology is crucial in industries where high precision and quality are required, as it minimizes contamination and oxidation of the materials being treated. The vacuum environment allows for uniform heat distribution, which results in consistent and reliable treatment outcomes. Vacuum furnaces are particularly valued for their ability to produce clean and bright finishes on metals, making them ideal for applications in aerospace, automotive, and medical device manufacturing. The global market for vacuum furnaces in heat treatment systems is expanding as industries increasingly demand high-performance materials with superior mechanical properties. This growth is driven by advancements in technology, which have improved the efficiency and capabilities of vacuum furnaces, making them more accessible and cost-effective for a wider range of applications. As industries continue to innovate and seek sustainable manufacturing practices, the demand for vacuum furnaces is expected to rise, reflecting their critical role in modern manufacturing processes.

Single Chamber Furnace, Double Chamber Furnace, Multi-chamber Furnace in the Vacuum Furnace in Heat Treatment Systems - Global Market:

Single chamber, double chamber, and multi-chamber furnaces are different configurations of vacuum furnaces used in heat treatment systems, each offering unique advantages and applications. A single chamber furnace is the most basic type, consisting of one chamber where the entire heat treatment process takes place. This design is straightforward and cost-effective, making it suitable for small-scale operations or applications where the treatment process is relatively simple. Single chamber furnaces are often used for processes like annealing and tempering, where the material does not require complex treatment cycles. On the other hand, double chamber furnaces feature two separate chambers, typically one for heating and the other for cooling. This configuration allows for more precise control over the treatment process, as materials can be rapidly transferred from the heating chamber to the cooling chamber, minimizing exposure to atmospheric conditions and reducing cycle times. Double chamber furnaces are ideal for applications requiring rapid quenching or where maintaining a specific atmosphere is critical. Multi-chamber furnaces take this concept further by incorporating multiple chambers, each dedicated to a specific stage of the heat treatment process. This setup allows for continuous processing of materials, improving efficiency and throughput. Multi-chamber furnaces are often used in high-volume production environments where consistency and speed are paramount. They are particularly beneficial in industries such as automotive and aerospace, where large quantities of components require precise and repeatable treatment. The choice between single, double, and multi-chamber furnaces depends on various factors, including the complexity of the treatment process, the volume of materials being processed, and the specific requirements of the application. As the global market for vacuum furnaces in heat treatment systems continues to grow, manufacturers are increasingly offering customizable solutions to meet the diverse needs of different industries. This trend is driving innovation in furnace design, with new technologies and features being developed to enhance performance, efficiency, and sustainability.

Aerospace, Industrial, Commercial, Others in the Vacuum Furnace in Heat Treatment Systems - Global Market:

Vacuum furnaces play a crucial role in heat treatment systems across various sectors, including aerospace, industrial, commercial, and others. In the aerospace industry, vacuum furnaces are essential for treating high-performance materials used in aircraft and spacecraft components. These materials often require precise heat treatment to achieve the desired mechanical properties, such as strength, durability, and resistance to extreme temperatures. Vacuum furnaces provide the controlled environment necessary to achieve these properties, ensuring that aerospace components meet stringent safety and performance standards. In the industrial sector, vacuum furnaces are used for a wide range of applications, from the production of high-strength steel and alloys to the treatment of specialized components used in machinery and equipment. The ability to perform heat treatment processes under vacuum conditions minimizes contamination and oxidation, resulting in superior material quality and performance. This is particularly important in industries where reliability and longevity are critical, such as automotive, energy, and manufacturing. In the commercial sector, vacuum furnaces are used for applications such as the production of consumer electronics, medical devices, and precision instruments. These products often require components with high precision and quality, which can be achieved through vacuum heat treatment. The use of vacuum furnaces in these applications ensures that components are free from defects and have the necessary properties to function effectively in their intended applications. Beyond these sectors, vacuum furnaces are also used in other areas, such as research and development, where they enable the exploration of new materials and processes. The versatility and precision of vacuum furnaces make them an invaluable tool in the development of innovative technologies and products. As industries continue to evolve and demand higher performance materials, the use of vacuum furnaces in heat treatment systems is expected to grow, reflecting their importance in modern manufacturing and technology development.

Vacuum Furnace in Heat Treatment Systems - Global Market Outlook:

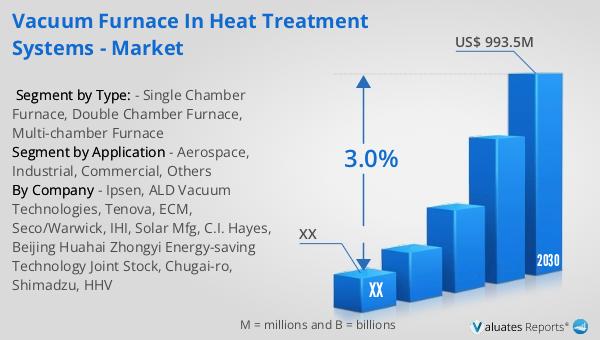

The global market for vacuum furnaces in heat treatment systems was valued at approximately $809 million in 2023, with projections indicating a growth to around $993.5 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.0% during the forecast period from 2024 to 2030. A significant factor contributing to this market expansion is the increasing emphasis on sustainable manufacturing practices across various industries. As companies strive to reduce their environmental impact and improve efficiency, vacuum furnaces offer an attractive solution due to their ability to perform heat treatment processes with minimal energy consumption and waste generation. The vacuum environment not only enhances the quality of the treated materials but also reduces the need for additional processing steps, further contributing to sustainability goals. Additionally, advancements in vacuum furnace technology are enabling more efficient and precise heat treatment processes, making them an increasingly viable option for a wider range of applications. As industries continue to prioritize sustainability and efficiency, the demand for vacuum furnaces in heat treatment systems is expected to rise, driving further growth in the global market. This trend underscores the critical role that vacuum furnaces play in modern manufacturing, as they help industries meet the challenges of producing high-quality materials while minimizing their environmental footprint.

| Report Metric | Details |

| Report Name | Vacuum Furnace in Heat Treatment Systems - Market |

| Forecasted market size in 2030 | US$ 993.5 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Ipsen, ALD Vacuum Technologies, Tenova, ECM, Seco/Warwick, IHI, Solar Mfg, C.I. Hayes, Beijing Huahai Zhongyi Energy-saving Technology Joint Stock, Chugai-ro, Shimadzu, HHV |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |