What is Jumbo Vacuum Furnaces - Global Market?

Jumbo vacuum furnaces are specialized industrial equipment used for high-temperature processing of materials in a vacuum environment. These furnaces are essential in industries where precise temperature control and contamination-free processing are critical. The global market for jumbo vacuum furnaces is characterized by its focus on advanced manufacturing processes, which require high-quality and reliable equipment. These furnaces are used in various applications, including heat treatment, brazing, sintering, and annealing of metals and alloys. The demand for jumbo vacuum furnaces is driven by the need for high-performance materials in industries such as aerospace, automotive, and electronics. As these industries continue to innovate and develop new technologies, the requirement for advanced materials processing equipment like jumbo vacuum furnaces is expected to grow. The market is also influenced by the increasing emphasis on energy efficiency and sustainability, as manufacturers seek to reduce their environmental impact while maintaining high production standards. Overall, the jumbo vacuum furnaces market is poised for steady growth, supported by technological advancements and the expanding applications of vacuum processing in various industries.

Horizontal, Vertical in the Jumbo Vacuum Furnaces - Global Market:

In the global market for jumbo vacuum furnaces, two primary configurations are prevalent: horizontal and vertical. Each configuration offers distinct advantages and is suited to specific applications, depending on the requirements of the manufacturing process. Horizontal jumbo vacuum furnaces are designed with a horizontal chamber orientation, making them ideal for processes that require easy loading and unloading of materials. This configuration is particularly beneficial for large-scale production environments where efficiency and speed are crucial. Horizontal furnaces are often used in the heat treatment of long or bulky components, such as turbine blades and large metal parts, where uniform heating is essential. The design allows for straightforward integration into automated production lines, enhancing productivity and reducing labor costs. On the other hand, vertical jumbo vacuum furnaces feature a vertical chamber orientation, which is advantageous for processes that require precise temperature control and uniform heat distribution. This configuration is often preferred for applications involving complex geometries or delicate materials that need careful handling. Vertical furnaces are commonly used in the aerospace and electronics industries, where the quality and consistency of the heat treatment process are paramount. The vertical design also minimizes the footprint of the equipment, making it suitable for facilities with limited space. Both horizontal and vertical jumbo vacuum furnaces are equipped with advanced control systems that ensure precise temperature regulation and process monitoring. These systems are crucial for maintaining the integrity of the materials being processed and achieving the desired mechanical properties. The choice between horizontal and vertical configurations depends on several factors, including the size and shape of the components, the specific heat treatment requirements, and the available space in the manufacturing facility. Manufacturers often consider the trade-offs between the two configurations to determine the most suitable option for their production needs. In addition to the basic configurations, jumbo vacuum furnaces can be customized with various features and accessories to enhance their performance and versatility. These may include specialized heating elements, advanced vacuum systems, and integrated cooling mechanisms. Customization allows manufacturers to tailor the equipment to their specific process requirements, ensuring optimal results and maximizing efficiency. As the demand for high-quality materials and components continues to rise, the global market for jumbo vacuum furnaces is expected to expand, driven by the need for advanced manufacturing solutions that can meet the stringent demands of modern industries.

Aerospace, Industrial, Commercial, Others in the Jumbo Vacuum Furnaces - Global Market:

Jumbo vacuum furnaces play a crucial role in various industries, including aerospace, industrial, commercial, and others, by providing high-temperature processing capabilities in a controlled vacuum environment. In the aerospace industry, these furnaces are essential for the heat treatment of critical components such as turbine blades, engine parts, and structural elements. The precise temperature control and contamination-free processing offered by jumbo vacuum furnaces ensure that aerospace components meet the stringent quality and performance standards required for safe and efficient operation. The ability to process high-performance alloys and composites is particularly important in this sector, where material properties directly impact the performance and reliability of aircraft and spacecraft. In the industrial sector, jumbo vacuum furnaces are used for a wide range of applications, including the heat treatment of metals, ceramics, and advanced materials. These furnaces enable manufacturers to achieve the desired mechanical properties, such as hardness, strength, and ductility, by carefully controlling the heating and cooling cycles. The versatility of jumbo vacuum furnaces makes them suitable for various industrial processes, including brazing, sintering, and annealing, which are essential for producing high-quality components used in machinery, tools, and equipment. In the commercial sector, jumbo vacuum furnaces are employed in the production of consumer goods and electronics, where precise material processing is critical for ensuring product quality and performance. These furnaces are used to manufacture components such as semiconductors, sensors, and electronic devices, where even minor deviations in material properties can significantly impact functionality. The ability to process materials in a vacuum environment minimizes the risk of contamination and ensures consistent results, making jumbo vacuum furnaces an indispensable tool in the commercial manufacturing landscape. Beyond these primary sectors, jumbo vacuum furnaces find applications in other areas, including research and development, where they are used to explore new materials and processes. The flexibility and precision offered by these furnaces make them valuable assets in laboratories and research facilities, where scientists and engineers work on developing innovative solutions for various industries. As the demand for advanced materials and high-performance components continues to grow, the usage of jumbo vacuum furnaces is expected to expand across different sectors, driven by the need for reliable and efficient processing solutions.

Jumbo Vacuum Furnaces - Global Market Outlook:

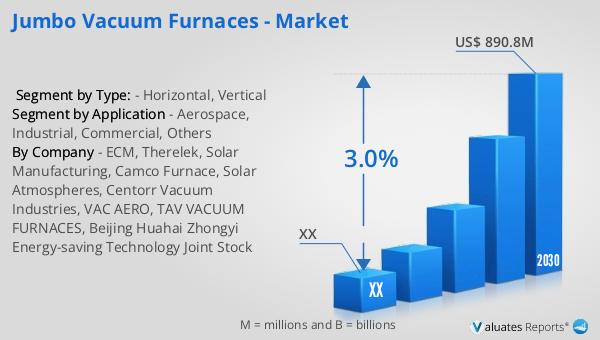

The global market for jumbo vacuum furnaces was valued at approximately $720 million in 2023, with projections indicating a growth to around $890.8 million by 2030. This growth represents a compound annual growth rate (CAGR) of 3.0% during the forecast period from 2024 to 2030. This upward trend is largely attributed to the increasing emphasis on sustainable manufacturing practices across various industries. As companies strive to reduce their environmental footprint and enhance energy efficiency, the demand for advanced processing equipment like jumbo vacuum furnaces is expected to rise. These furnaces offer significant advantages in terms of energy consumption and emissions reduction, making them an attractive option for manufacturers seeking to align with global sustainability goals. The ability to process materials in a vacuum environment not only improves product quality but also minimizes waste and reduces the need for additional processing steps, further contributing to sustainability efforts. As industries continue to prioritize eco-friendly practices, the market for jumbo vacuum furnaces is likely to experience steady growth, driven by the need for efficient and environmentally responsible manufacturing solutions. The focus on sustainable practices is expected to shape the future of the jumbo vacuum furnaces market, as manufacturers seek to balance productivity with environmental stewardship.

| Report Metric | Details |

| Report Name | Jumbo Vacuum Furnaces - Market |

| Forecasted market size in 2030 | US$ 890.8 million |

| CAGR | 3.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ECM, Therelek, Solar Manufacturing, Camco Furnace, Solar Atmospheres, Centorr Vacuum Industries, VAC AERO, TAV VACUUM FURNACES, Beijing Huahai Zhongyi Energy-saving Technology Joint Stock |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |