What is Global Medical Component Brazing Services Market?

The Global Medical Component Brazing Services Market is a specialized sector within the broader medical device industry that focuses on the joining of metal components using a process called brazing. Brazing is a technique where two or more metals are joined together by melting and flowing a filler metal into the joint, which has a lower melting point than the adjoining metals. This method is particularly useful in the medical field because it creates strong, durable bonds that can withstand the rigorous demands of medical applications. The market for these services is driven by the increasing complexity and miniaturization of medical devices, which require precise and reliable joining techniques. Companies in this market offer a range of services, including the brazing of various metals and alloys, to meet the stringent requirements of medical device manufacturers. The demand for high-quality, reliable medical components is growing, and brazing services play a crucial role in ensuring that these components meet the necessary standards for safety and performance.

Brazing Services for Metallic Materials, Brazing services for Non-metallic Materials in the Global Medical Component Brazing Services Market:

Brazing services for metallic materials in the Global Medical Component Brazing Services Market involve the joining of metals such as stainless steel, titanium, and various alloys. These materials are commonly used in medical devices due to their strength, durability, and biocompatibility. The brazing process for metallic materials typically involves heating the metals to a high temperature and then introducing a filler metal that melts and flows into the joint. This creates a strong, leak-proof bond that can withstand the harsh conditions often encountered in medical applications. On the other hand, brazing services for non-metallic materials, such as ceramics and certain polymers, require specialized techniques and materials. These non-metallic materials are often used in medical devices for their unique properties, such as electrical insulation or biocompatibility. The brazing process for non-metallic materials can be more complex, as it often requires the use of specialized filler materials and precise temperature control to avoid damaging the components. Both metallic and non-metallic brazing services are essential in the medical field, as they enable the creation of complex, high-performance devices that are critical for patient care. The ability to reliably join different materials expands the possibilities for medical device design and innovation, allowing for the development of new and improved treatments and diagnostic tools.

Electrosurgical Instruments, X-ray Assemblies, Implantable Assemblies, Life science Components in the Global Medical Component Brazing Services Market:

The usage of Global Medical Component Brazing Services Market in areas such as electrosurgical instruments, X-ray assemblies, implantable assemblies, and life science components is extensive and varied. Electrosurgical instruments, which are used in procedures that require cutting or coagulating tissue, rely on brazing services to ensure that their metal components are securely joined and can withstand the high temperatures generated during use. The precision and reliability of brazed joints are crucial for the safety and effectiveness of these instruments. In X-ray assemblies, brazing is used to join components such as tubes and connectors, which must be able to withstand high voltages and provide reliable performance over time. The strong, leak-proof joints created by brazing are essential for maintaining the integrity of these assemblies and ensuring accurate diagnostic results. Implantable assemblies, such as pacemakers and orthopedic implants, also benefit from brazing services. The biocompatibility and strength of brazed joints make them ideal for use in devices that must function reliably within the human body. Finally, life science components, which include a wide range of devices used in research and diagnostics, often require the precise and reliable joining of various materials. Brazing services enable the creation of complex, high-performance components that are essential for advancing medical research and improving patient care.

Global Medical Component Brazing Services Market Outlook:

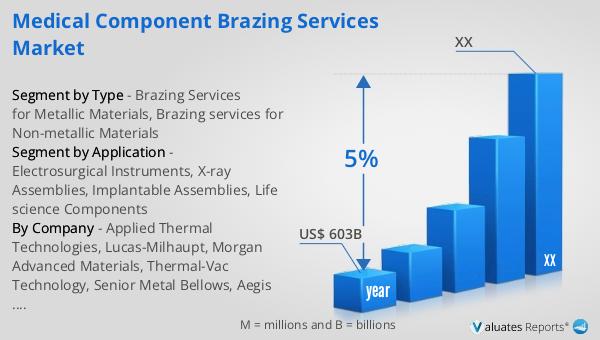

According to our research, the global market for medical devices is projected to reach approximately US$ 603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, an aging global population, and increasing demand for healthcare services. The medical device industry encompasses a wide range of products, from simple instruments to complex diagnostic and therapeutic devices. As the market continues to expand, the demand for high-quality, reliable components will also increase, driving the need for specialized services such as brazing. Companies that provide brazing services for medical components are well-positioned to benefit from this growth, as their expertise in creating strong, durable joints is essential for the development of advanced medical devices. The ability to join different materials reliably and precisely is critical for ensuring the safety and effectiveness of these devices, making brazing services a vital part of the medical device manufacturing process.

| Report Metric | Details |

| Report Name | Medical Component Brazing Services Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Applied Thermal Technologies, Lucas-Milhaupt, Morgan Advanced Materials, Thermal-Vac Technology, Senior Metal Bellows, Aegis Technology, GCM, MiQ Partners, DFF Corporation, FM Industries, STC Material Solutions, California Brazing & Nevada Heat Treating, Ridge Engineering, Storm Power Components, ThermoFusion, Twigg Corporation, Apex Wire Products, Vacuum Process Engineering, Marshall Manufacturing Company, Mac Machine Company, G & M Metal Fabricators, Brinkman Precision, MicroGroup, Cook Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |