What is Global Medical Sheet Metal Fabrication Market?

The Global Medical Sheet Metal Fabrication Market refers to the industry involved in the design, manufacture, and processing of sheet metal components specifically for medical devices and equipment. This market is crucial as it provides the structural and functional parts necessary for a wide range of medical devices, from surgical instruments to diagnostic machines. The fabrication process involves cutting, bending, and assembling metal sheets to create precise and durable components that meet stringent medical standards. The demand for high-quality, reliable medical devices drives the need for advanced fabrication techniques and materials. This market is characterized by continuous innovation and technological advancements to improve the efficiency, accuracy, and safety of medical devices. The global nature of this market means that it serves healthcare systems worldwide, contributing to better patient care and medical outcomes.

Design, Manufacture, Detection in the Global Medical Sheet Metal Fabrication Market:

The design phase in the Global Medical Sheet Metal Fabrication Market is critical as it sets the foundation for the entire manufacturing process. Engineers and designers work closely to create detailed blueprints and 3D models of the required components. These designs must adhere to strict medical standards and regulations to ensure the safety and efficacy of the final product. Advanced software tools are often used to simulate the performance of the components under various conditions, allowing for optimization before actual production begins. Once the design is finalized, the manufacturing phase takes over. This involves cutting, bending, and assembling metal sheets using various techniques such as laser cutting, stamping, and welding. Precision is paramount in this phase to ensure that each component meets the exact specifications outlined in the design. Quality control measures are implemented at every stage to detect and rectify any deviations or defects. Detection and inspection are integral parts of the manufacturing process. Advanced technologies such as X-ray inspection, ultrasonic testing, and automated optical inspection are employed to ensure that the fabricated components are free from defects and meet all regulatory requirements. These detection methods help in identifying any issues early in the production process, thereby reducing waste and improving overall efficiency. The entire process, from design to detection, is a collaborative effort involving multiple stakeholders, including engineers, designers, quality control experts, and regulatory bodies. This collaboration ensures that the final product is not only functional and reliable but also safe for medical use. The continuous advancements in technology and materials further enhance the capabilities of the Global Medical Sheet Metal Fabrication Market, making it an indispensable part of the healthcare industry.

Metal, Alloy in the Global Medical Sheet Metal Fabrication Market:

The usage of the Global Medical Sheet Metal Fabrication Market in the areas of metal and alloy is extensive and multifaceted. Metals such as stainless steel, aluminum, and titanium are commonly used in the fabrication of medical devices due to their durability, corrosion resistance, and biocompatibility. Stainless steel, for instance, is widely used in surgical instruments, implants, and hospital equipment because of its strength and resistance to rust and staining. Aluminum, being lightweight and highly conductive, is often used in diagnostic equipment and medical imaging devices. Titanium, known for its exceptional strength-to-weight ratio and biocompatibility, is frequently used in orthopedic implants and dental devices. Alloys, which are combinations of two or more metals, also play a significant role in medical sheet metal fabrication. Alloys such as nitinol, a nickel-titanium alloy, are used in stents and other medical devices that require flexibility and shape memory. The unique properties of these metals and alloys make them ideal for various medical applications, ensuring that the devices are not only functional but also safe and reliable. The fabrication process for these metals and alloys involves advanced techniques such as laser cutting, CNC machining, and precision welding to achieve the desired shapes and specifications. Quality control is a critical aspect of this process, with rigorous testing and inspection methods employed to ensure that the final products meet all regulatory standards and performance criteria. The use of metals and alloys in the Global Medical Sheet Metal Fabrication Market is a testament to the industry's commitment to innovation and excellence, providing healthcare professionals with the tools they need to deliver high-quality patient care.

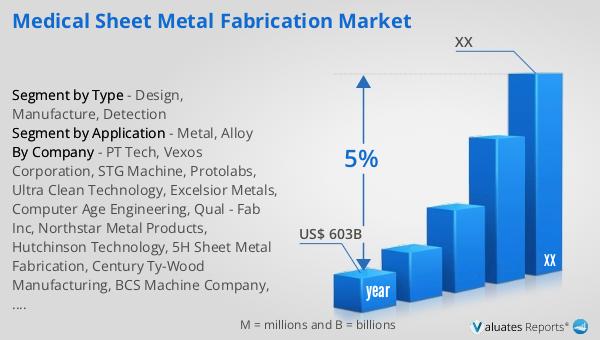

Global Medical Sheet Metal Fabrication Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately USD 603 billion in 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by several factors, including the increasing demand for advanced medical technologies, the rising prevalence of chronic diseases, and the expanding healthcare infrastructure in emerging markets. The continuous advancements in medical device technology, coupled with the growing emphasis on patient safety and care, are expected to fuel the market's expansion. Additionally, the aging global population and the increasing need for minimally invasive surgical procedures are contributing to the rising demand for innovative medical devices. The market's growth is also supported by favorable government policies and increased investment in healthcare research and development. As a result, the Global Medical Sheet Metal Fabrication Market is poised to play a crucial role in meeting the evolving needs of the healthcare industry, providing high-quality, reliable components for a wide range of medical devices.

| Report Metric | Details |

| Report Name | Medical Sheet Metal Fabrication Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | PT Tech, Vexos Corporation, STG Machine, Protolabs, Ultra Clean Technology, Excelsior Metals, Computer Age Engineering, Qual - Fab Inc, Northstar Metal Products, Hutchinson Technology, 5H Sheet Metal Fabrication, Century Ty-Wood Manufacturing, BCS Machine Company, Elite Manufacturing Technologies, MSP Aviation, Atrenne Integrated Solutions, Atlas Manufacturing, Snowline Aerospace, Heiden, Arnprior Rapid Manufacturing Solutions, Stanron Steel Specialties, Source International, ZETWERK Manufacturing, Xometry, Franklin Sheet Metal, CSI Industries, Stueken, TWH Enterprises |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |