What is Global Anti-Corrosion Lining Market?

The Global Anti-Corrosion Lining Market is a specialized sector focused on providing protective coatings to prevent corrosion in various industrial applications. Corrosion is a natural process that deteriorates materials, especially metals, due to chemical reactions with their environment. Anti-corrosion linings are essential in extending the lifespan of equipment, structures, and pipelines by creating a barrier against corrosive elements. These linings are used in a wide range of industries, including chemical, oil and gas, pharmaceutical, and marine, among others. The market for anti-corrosion linings is driven by the need to reduce maintenance costs, enhance safety, and comply with stringent environmental regulations. With advancements in technology, the market has seen the development of more effective and durable lining solutions, catering to the specific needs of different industries. The global demand for anti-corrosion linings is expected to grow as industries continue to seek ways to protect their investments and ensure operational efficiency.

Rubber Lining, Plastic Lining, Glass Lining, Ceramic Lining in the Global Anti-Corrosion Lining Market:

Rubber lining, plastic lining, glass lining, and ceramic lining are various types of anti-corrosion linings used in the Global Anti-Corrosion Lining Market, each offering unique benefits and applications. Rubber lining is widely used due to its excellent resistance to a variety of chemicals and its flexibility, which allows it to absorb mechanical shocks and vibrations. It is commonly applied in tanks, pipes, and equipment in the chemical and mining industries. Plastic lining, on the other hand, offers superior resistance to a broad spectrum of corrosive substances, including acids, alkalis, and solvents. It is lightweight, easy to install, and often used in applications where metal linings would be too heavy or susceptible to corrosion. Glass lining combines the strength of steel with the chemical resistance of glass, making it ideal for use in reactors, storage tanks, and pipelines in the pharmaceutical and chemical industries. The smooth, non-porous surface of glass linings prevents contamination and is easy to clean, which is crucial in maintaining product purity. Ceramic lining is known for its exceptional hardness and wear resistance, making it suitable for applications involving abrasive materials. It is often used in industries such as mining, power generation, and wastewater treatment, where equipment is exposed to harsh conditions. Each type of lining has its own set of advantages and is selected based on the specific requirements of the application, such as the type of corrosive environment, temperature, and mechanical stresses involved. The choice of lining material is critical in ensuring the longevity and efficiency of industrial equipment, thereby reducing downtime and maintenance costs.

Chemical Industry, Oil Industry, Pharmaceutical Industry in the Global Anti-Corrosion Lining Market:

The usage of anti-corrosion linings in the chemical industry is crucial due to the highly corrosive nature of many chemicals used in production processes. These linings protect storage tanks, reactors, and pipelines from chemical attacks, ensuring the integrity and safety of the equipment. In the oil industry, anti-corrosion linings are essential for protecting pipelines, storage tanks, and offshore structures from the harsh marine environment and the corrosive nature of crude oil and its derivatives. The use of these linings helps in preventing leaks and spills, which can have catastrophic environmental and financial consequences. In the pharmaceutical industry, anti-corrosion linings are used to maintain the purity of products by preventing contamination from corroded equipment. The linings are applied to reactors, storage tanks, and piping systems to ensure that the highly sensitive pharmaceutical products are not compromised. The use of anti-corrosion linings in these industries not only extends the lifespan of the equipment but also enhances safety, reduces maintenance costs, and ensures compliance with stringent regulatory standards. The demand for anti-corrosion linings in these sectors is driven by the need to protect valuable assets, ensure operational efficiency, and meet environmental and safety regulations.

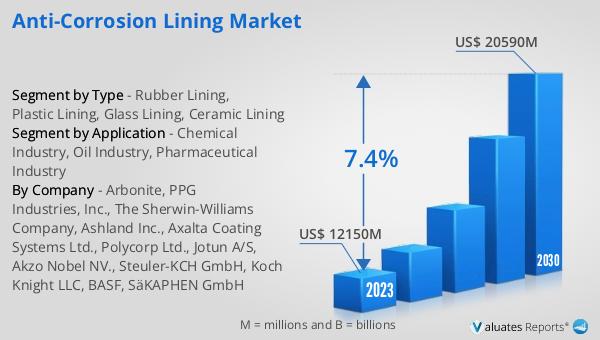

Global Anti-Corrosion Lining Market Outlook:

The global Anti-Corrosion Lining market was valued at US$ 12,150 million in 2023 and is anticipated to reach US$ 20,590 million by 2030, witnessing a CAGR of 7.4% during the forecast period 2024-2030. This significant growth is attributed to the increasing demand for protective coatings in various industries to prevent corrosion and extend the lifespan of equipment and structures. The market is driven by the need to reduce maintenance costs, enhance safety, and comply with stringent environmental regulations. With advancements in technology, more effective and durable lining solutions are being developed, catering to the specific needs of different industries. The growing awareness about the benefits of anti-corrosion linings and the rising investments in infrastructure development are also contributing to the market's expansion. As industries continue to seek ways to protect their investments and ensure operational efficiency, the demand for anti-corrosion linings is expected to grow steadily. The market outlook indicates a positive trend, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Anti-Corrosion Lining Market |

| Accounted market size in 2023 | US$ 12150 million |

| Forecasted market size in 2030 | US$ 20590 million |

| CAGR | 7.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Arbonite, PPG Industries, Inc., The Sherwin-Williams Company, Ashland Inc., Axalta Coating Systems Ltd., Polycorp Ltd., Jotun A/S, Akzo Nobel NV., Steuler-KCH GmbH, Koch Knight LLC, BASF, SäKAPHEN GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |