What is Global Nitrogen Gas Spring Cylinder Market?

The Global Nitrogen Gas Spring Cylinder Market refers to the worldwide industry focused on the production, distribution, and application of nitrogen gas spring cylinders. These cylinders are mechanical devices that use compressed nitrogen gas to exert a force, making them essential in various industrial applications. They are commonly used in automotive manufacturing, electronics, and other sectors that require precise and reliable force control. The market encompasses a wide range of products, including standard, compact, super compact, and micro gas spring cylinders, each designed to meet specific needs and applications. The demand for these cylinders is driven by their efficiency, durability, and ability to provide consistent performance under varying conditions. As industries continue to seek advanced solutions for automation and precision engineering, the global nitrogen gas spring cylinder market is expected to grow, offering innovative products that cater to the evolving needs of different sectors.

Standard, Compact, Super Compact, Micro in the Global Nitrogen Gas Spring Cylinder Market:

Standard, compact, super compact, and micro nitrogen gas spring cylinders are different types of gas springs designed to meet specific requirements in various applications. Standard nitrogen gas spring cylinders are the most commonly used type, offering a balance of size and force. They are versatile and can be used in a wide range of applications, from automotive manufacturing to industrial machinery. These cylinders are known for their durability and reliability, making them a popular choice for many industries. Compact nitrogen gas spring cylinders are smaller in size compared to standard cylinders but still provide a significant amount of force. They are ideal for applications where space is limited but a high level of force is required. These cylinders are often used in precision engineering and electronics manufacturing, where space constraints are a common challenge. Super compact nitrogen gas spring cylinders are even smaller than compact cylinders, offering a high force output in an extremely small package. These cylinders are designed for applications where both space and weight are critical factors. They are commonly used in advanced manufacturing processes, such as semiconductor production and medical device manufacturing, where precision and compactness are essential. Micro nitrogen gas spring cylinders are the smallest type of gas springs, designed for applications that require minimal space and precise force control. These cylinders are used in highly specialized industries, such as aerospace and defense, where every millimeter of space and every gram of weight can make a significant difference. Despite their small size, micro gas spring cylinders are capable of providing a high level of force, making them suitable for demanding applications. Each type of nitrogen gas spring cylinder offers unique advantages, allowing industries to choose the most appropriate solution for their specific needs. The availability of different sizes and force outputs ensures that there is a nitrogen gas spring cylinder for almost any application, from large-scale industrial machinery to delicate electronic components.

Automotive, Electronics, Others in the Global Nitrogen Gas Spring Cylinder Market:

The usage of global nitrogen gas spring cylinders spans across various industries, including automotive, electronics, and others. In the automotive industry, nitrogen gas spring cylinders are widely used in the manufacturing process to provide precise force control and improve efficiency. They are commonly found in stamping presses, where they help in the forming and shaping of metal parts. The consistent force provided by these cylinders ensures high-quality production and reduces the risk of defects. Additionally, nitrogen gas spring cylinders are used in the assembly of automotive components, such as seats and doors, where they assist in the smooth and controlled movement of parts. In the electronics industry, nitrogen gas spring cylinders play a crucial role in the production of electronic devices. They are used in the manufacturing of circuit boards, where precise force control is essential to ensure the proper placement and connection of components. The compact and super compact cylinders are particularly useful in this industry due to the limited space available in electronic manufacturing equipment. Furthermore, nitrogen gas spring cylinders are used in the assembly of electronic devices, such as smartphones and laptops, where they help in the precise alignment and fitting of components. Beyond automotive and electronics, nitrogen gas spring cylinders find applications in various other industries. In the packaging industry, they are used in machinery that requires consistent force for sealing and cutting operations. The medical device industry also benefits from the use of nitrogen gas spring cylinders, particularly in the manufacturing of precision instruments and equipment. These cylinders provide the necessary force control to ensure the accuracy and reliability of medical devices. Additionally, nitrogen gas spring cylinders are used in the aerospace industry, where they contribute to the production of aircraft components and systems. The ability to provide consistent force in a compact and lightweight package makes these cylinders ideal for aerospace applications. Overall, the versatility and reliability of nitrogen gas spring cylinders make them indispensable in a wide range of industries, driving their demand and growth in the global market.

Global Nitrogen Gas Spring Cylinder Market Outlook:

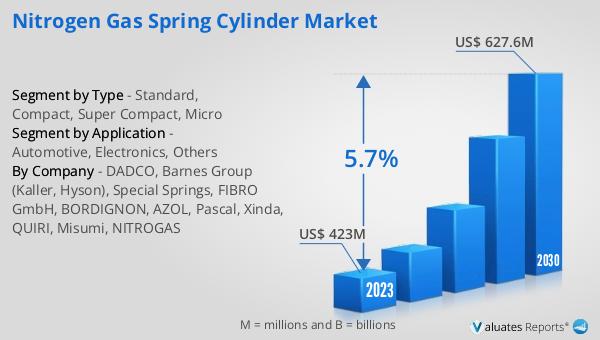

The global nitrogen gas spring cylinder market was valued at US$ 423 million in 2023 and is anticipated to reach US$ 627.6 million by 2030, witnessing a CAGR of 5.7% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for nitrogen gas spring cylinders across various industries. The automotive industry, in particular, is expected to contribute significantly to this growth, as manufacturers continue to seek advanced solutions for improving production efficiency and product quality. Similarly, the electronics industry is likely to drive demand for compact and super compact nitrogen gas spring cylinders, given the need for precise force control in the manufacturing of electronic devices. The versatility of these cylinders, coupled with their ability to provide consistent performance under varying conditions, makes them a preferred choice in many applications. As industries continue to evolve and adopt new technologies, the demand for reliable and efficient force control solutions like nitrogen gas spring cylinders is expected to rise, further propelling the growth of the global market. This positive market outlook underscores the importance of nitrogen gas spring cylinders in modern manufacturing and highlights the potential for continued innovation and development in this sector.

| Report Metric | Details |

| Report Name | Nitrogen Gas Spring Cylinder Market |

| Accounted market size in 2023 | US$ 423 million |

| Forecasted market size in 2030 | US$ 627.6 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DADCO, Barnes Group (Kaller, Hyson), Special Springs, FIBRO GmbH, BORDIGNON, AZOL, Pascal, Xinda, QUIRI, Misumi, NITROGAS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |