What is Global Medical Engraving Market?

The Global Medical Engraving Market is a specialized sector within the broader medical device industry that focuses on the precise marking and engraving of medical instruments and devices. This market encompasses various technologies and methods used to engrave or mark medical tools, ensuring they meet stringent regulatory standards and are easily identifiable. These engravings are crucial for traceability, quality control, and compliance with health regulations. The market includes a wide range of applications, from surgical instruments to implants, and utilizes advanced technologies such as laser engraving, dot peen marking, and chemical etching. The demand for high-quality, durable, and precise engravings is driven by the need for enhanced patient safety, efficient inventory management, and the prevention of counterfeiting. As the medical device industry continues to grow, the Global Medical Engraving Market is expected to expand, offering innovative solutions to meet the evolving needs of healthcare providers and manufacturers.

Dot Peen Engraving, Vector Cutting in the Global Medical Engraving Market:

Dot Peen Engraving and Vector Cutting are two prominent techniques used in the Global Medical Engraving Market. Dot Peen Engraving, also known as pin marking, involves a stylus that strikes the surface of a material to create a series of dots that form characters or patterns. This method is highly durable and can be used on a variety of materials, including metals and plastics. It is particularly valued for its ability to produce deep, permanent marks that are resistant to wear and corrosion, making it ideal for medical instruments that undergo frequent sterilization. On the other hand, Vector Cutting, often performed using laser technology, involves directing a focused beam of light to cut or engrave materials with high precision. This technique is known for its accuracy and ability to create intricate designs and fine details, which are essential for marking small medical devices and components. Vector Cutting is versatile and can be used on a wide range of materials, including metals, ceramics, and polymers. Both Dot Peen Engraving and Vector Cutting play a crucial role in the medical engraving market by ensuring that medical devices are properly labeled, traceable, and compliant with regulatory standards. These technologies help in maintaining the integrity and safety of medical instruments, ultimately contributing to better patient care and operational efficiency in healthcare settings.

Metal, Non-metal in the Global Medical Engraving Market:

The usage of the Global Medical Engraving Market spans across both metal and non-metal materials, each with its unique applications and benefits. In the realm of metals, engraving is commonly applied to surgical instruments, implants, and other critical medical devices. Metals such as stainless steel, titanium, and aluminum are frequently used due to their durability, resistance to corrosion, and biocompatibility. Engraving on these materials ensures that each instrument or device is uniquely identifiable, which is essential for traceability and inventory management. For instance, surgical instruments often have engraved serial numbers, barcodes, or QR codes that allow for easy tracking and maintenance. This not only enhances operational efficiency but also ensures compliance with stringent regulatory requirements. In the case of implants, engraving provides critical information such as the manufacturer’s details, batch numbers, and specifications, which are vital for patient safety and post-operative care. On the other hand, non-metal materials such as plastics, ceramics, and polymers are also widely used in the medical field. These materials are often employed in the production of disposable medical devices, packaging, and components of diagnostic equipment. Engraving on non-metals requires specialized techniques to ensure that the markings are clear, durable, and do not compromise the integrity of the material. For example, laser engraving is commonly used on plastic components to create precise and permanent marks without causing any damage. This is particularly important for items like syringes, catheters, and other single-use devices where clear identification is crucial for preventing errors and ensuring patient safety. Additionally, non-metal engravings are used in the labeling of medical packaging, providing essential information such as expiration dates, usage instructions, and safety warnings. Overall, the Global Medical Engraving Market plays a vital role in enhancing the safety, traceability, and efficiency of medical devices and instruments, whether they are made of metal or non-metal materials.

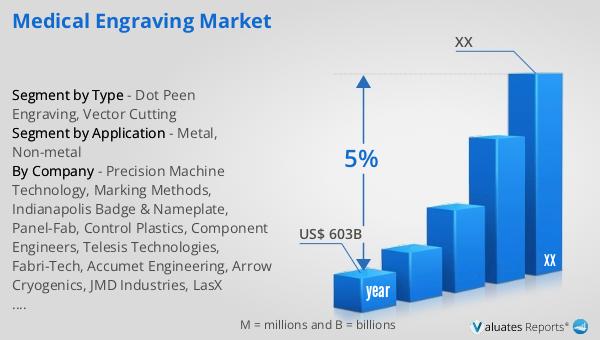

Global Medical Engraving Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This significant market size underscores the critical role that medical devices play in the healthcare industry, driving advancements in patient care, diagnostics, and treatment. The steady growth rate reflects the increasing demand for innovative medical technologies, improved healthcare infrastructure, and the rising prevalence of chronic diseases. As the market continues to expand, the importance of precise and reliable engraving on medical devices becomes even more pronounced. Engraving ensures that medical instruments and devices are easily identifiable, traceable, and compliant with regulatory standards, which is essential for maintaining high levels of patient safety and operational efficiency. The growth of the Global Medical Engraving Market is intrinsically linked to the broader medical device market, as the need for accurate and durable markings on medical tools and equipment continues to rise. This growth trajectory highlights the ongoing advancements in engraving technologies and their critical role in supporting the evolving needs of the healthcare sector.

| Report Metric | Details |

| Report Name | Medical Engraving Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Precision Machine Technology, Marking Methods, Indianapolis Badge & Nameplate, Panel-Fab, Control Plastics, Component Engineers, Telesis Technologies, Fabri-Tech, Accumet Engineering, Arrow Cryogenics, JMD Industries, LasX Industries, Precision Electronic Glass(PEG), Faspro Technologies, Pro-Type Industries, US Anodize, Thermal Plastic Design, Prime Products, Multimetal Products, Prototype Solutions Group, Sanken Industry, Pilkington Metal Finishing, Crow Corporation, Peridot Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |