What is Global Chemical Transfer and Dosing Pumps Market?

The global Chemical Transfer and Dosing Pumps market is a specialized segment within the broader industrial pumps market. These pumps are designed to handle and transfer chemicals safely and efficiently, ensuring precise dosing and minimal waste. The market encompasses a variety of pumps, including those used for transferring chemicals from one container to another and those designed for metering or dosing specific amounts of chemicals into a process. The demand for these pumps is driven by their critical role in various industries such as oil and gas, chemicals, water and wastewater treatment, and building construction. As industries continue to grow and regulations around chemical handling become more stringent, the need for reliable and efficient chemical transfer and dosing pumps is expected to rise. These pumps not only enhance operational efficiency but also ensure safety and compliance with environmental standards. The market is characterized by technological advancements, with manufacturers focusing on developing pumps that offer higher precision, better durability, and enhanced automation features.

Chemical Transfer Pump, Chemical Metering Pump in the Global Chemical Transfer and Dosing Pumps Market:

Chemical transfer pumps and chemical metering pumps are integral components of the global Chemical Transfer and Dosing Pumps market. Chemical transfer pumps are primarily used to move chemicals from one location to another, ensuring safe and efficient handling of potentially hazardous substances. These pumps are designed to withstand the corrosive nature of chemicals, featuring materials like stainless steel, plastic, or specialized alloys that resist chemical degradation. They are commonly used in industries such as oil and gas, where they transfer chemicals for refining processes, and in the chemical industry, where they handle a variety of substances used in manufacturing. On the other hand, chemical metering pumps, also known as dosing pumps, are designed to deliver precise amounts of chemicals into a process or system. These pumps are crucial in applications where accurate dosing is essential, such as in water and wastewater treatment, where they add disinfectants or pH adjusters to ensure water quality. In the building construction industry, chemical metering pumps are used to add additives to concrete or other building materials to enhance their properties. Both types of pumps are essential for maintaining operational efficiency, safety, and compliance with regulatory standards. The global market for these pumps is driven by the increasing demand for automation and precision in industrial processes, as well as the need for safe and efficient chemical handling solutions. Manufacturers are continually innovating to develop pumps that offer higher accuracy, better durability, and enhanced control features. This includes the integration of digital technologies and smart features that allow for remote monitoring and control, further enhancing the efficiency and reliability of these pumps. As industries continue to evolve and the demand for high-quality, reliable chemical handling solutions grows, the market for chemical transfer and metering pumps is expected to expand, offering numerous opportunities for manufacturers and end-users alike.

Oil and Gas, Chemicals, Building Construction, Generate Electricity, Water and Wastewater Treatment, Other in the Global Chemical Transfer and Dosing Pumps Market:

The global Chemical Transfer and Dosing Pumps market finds extensive usage across various industries, including oil and gas, chemicals, building construction, electricity generation, and water and wastewater treatment. In the oil and gas industry, these pumps are essential for transferring and dosing chemicals used in drilling, refining, and production processes. They ensure the safe and efficient handling of corrosive and hazardous chemicals, which is critical for maintaining operational safety and compliance with environmental regulations. In the chemical industry, these pumps are used to handle a wide range of substances, from raw materials to finished products, ensuring precise dosing and minimal waste. This is particularly important in processes where the accurate mixing of chemicals is crucial for product quality and consistency. In the building construction industry, chemical transfer and dosing pumps are used to add additives to concrete and other building materials, enhancing their properties and performance. These pumps ensure that the correct amount of additives is mixed into the materials, improving their strength, durability, and other characteristics. In the electricity generation sector, chemical dosing pumps are used to add chemicals to cooling water and other systems to prevent corrosion, scaling, and other issues that can affect the efficiency and longevity of equipment. Water and wastewater treatment is another critical area where these pumps are used extensively. They are used to add disinfectants, pH adjusters, and other chemicals to water and wastewater to ensure that it meets quality standards and is safe for discharge or reuse. The precise dosing capabilities of these pumps are essential for maintaining water quality and compliance with regulatory standards. Other industries that use chemical transfer and dosing pumps include pharmaceuticals, food and beverage, and agriculture, where they are used to handle and dose a variety of chemicals and additives. The versatility and reliability of these pumps make them indispensable in a wide range of applications, driving their demand in the global market.

Global Chemical Transfer and Dosing Pumps Market Outlook:

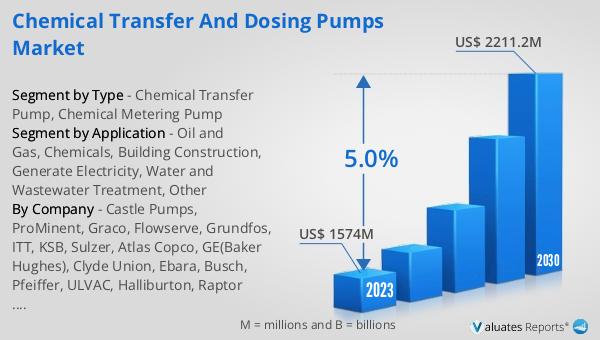

The global Chemical Transfer and Dosing Pumps market was valued at US$ 1574 million in 2023 and is projected to reach US$ 2211.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for efficient and reliable chemical handling solutions across various industries. As industries continue to expand and regulatory requirements for chemical handling become more stringent, the need for advanced chemical transfer and dosing pumps is expected to rise. These pumps play a crucial role in ensuring operational efficiency, safety, and compliance with environmental standards. Manufacturers are focusing on developing innovative pumps that offer higher precision, better durability, and enhanced automation features to meet the evolving needs of end-users. The integration of digital technologies and smart features is also becoming more prevalent, allowing for remote monitoring and control of pump operations. This not only enhances the efficiency and reliability of these pumps but also provides valuable data for predictive maintenance and process optimization. As a result, the global market for chemical transfer and dosing pumps is poised for significant growth, offering numerous opportunities for manufacturers and end-users alike.

| Report Metric | Details |

| Report Name | Chemical Transfer and Dosing Pumps Market |

| Accounted market size in 2023 | US$ 1574 million |

| Forecasted market size in 2030 | US$ 2211.2 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Castle Pumps, ProMinent, Graco, Flowserve, Grundfos, ITT, KSB, Sulzer, Atlas Copco, GE(Baker Hughes), Clyde Union, Ebara, Busch, Pfeiffer, ULVAC, Halliburton, Raptor Supplies, Little Giant, Michael Smith Engineers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |