What is Global Atmospheric Pipeline Coatings Market?

The Global Atmospheric Pipeline Coatings Market refers to the industry focused on providing protective coatings for pipelines exposed to atmospheric conditions. These coatings are essential for safeguarding pipelines from corrosion, weathering, and other environmental factors that can compromise their integrity and functionality. The market encompasses a variety of coating types, each designed to address specific challenges associated with different atmospheric conditions. The coatings are applied to pipelines used in various sectors, including petroleum gas, industrial fields, chemical treatment, and city water supply. The primary goal of these coatings is to extend the lifespan of pipelines, reduce maintenance costs, and ensure the safe and efficient transport of materials. The market is driven by the increasing demand for energy and the need for reliable infrastructure to support this demand. Technological advancements and stringent environmental regulations also play a significant role in shaping the market dynamics. Companies operating in this market invest heavily in research and development to create innovative coating solutions that meet the evolving needs of the industry.

Epoxy Anticorrosive Coating, Fluorocarbon Coating, Polyurethane Coating, Others in the Global Atmospheric Pipeline Coatings Market:

Epoxy Anticorrosive Coating is one of the most widely used types of coatings in the Global Atmospheric Pipeline Coatings Market. This type of coating is known for its excellent adhesion properties and resistance to corrosion, making it ideal for protecting pipelines from harsh environmental conditions. Epoxy coatings are typically composed of an epoxy resin and a curing agent, which react to form a hard, durable surface. This coating is particularly effective in environments where pipelines are exposed to moisture, chemicals, and varying temperatures. Fluorocarbon Coating, on the other hand, offers superior resistance to UV radiation and weathering. This type of coating is often used in pipelines that are exposed to extreme weather conditions, as it provides long-lasting protection against degradation caused by sunlight and other environmental factors. Fluorocarbon coatings are also known for their non-stick properties, which help prevent the buildup of contaminants on the pipeline surface. Polyurethane Coating is another important type of coating in this market. It is valued for its flexibility and impact resistance, making it suitable for pipelines that experience mechanical stress and movement. Polyurethane coatings also offer good resistance to chemicals and abrasion, ensuring the longevity of the pipeline. Other types of coatings in the Global Atmospheric Pipeline Coatings Market include zinc-rich coatings, which provide sacrificial protection by corroding in place of the pipeline, and ceramic coatings, which offer high-temperature resistance and durability. Each type of coating has its unique advantages and is selected based on the specific requirements of the pipeline and the environmental conditions it will be exposed to. The choice of coating is crucial in ensuring the pipeline's performance, safety, and longevity. Companies in this market continuously innovate to develop coatings that offer enhanced protection and meet the stringent standards set by regulatory bodies.

Petroleum Gas, Industrial Field, Chemical Treatment, City Water Supply, Others in the Global Atmospheric Pipeline Coatings Market:

The Global Atmospheric Pipeline Coatings Market finds extensive usage in various sectors, including petroleum gas, industrial fields, chemical treatment, city water supply, and others. In the petroleum gas sector, these coatings are crucial for protecting pipelines that transport crude oil, natural gas, and other petroleum products. The harsh environmental conditions and the corrosive nature of the transported materials necessitate the use of robust coatings to prevent pipeline failures and leaks. In industrial fields, atmospheric pipeline coatings are used to protect pipelines that carry raw materials, chemicals, and other industrial products. These coatings help maintain the integrity of the pipelines, ensuring the safe and efficient transport of materials. Chemical treatment facilities also rely heavily on these coatings to protect pipelines from the corrosive effects of various chemicals. The coatings provide a barrier that prevents the chemicals from reacting with the pipeline material, thereby extending the pipeline's lifespan and reducing maintenance costs. In city water supply systems, atmospheric pipeline coatings are used to protect pipelines that transport drinking water. These coatings ensure that the water remains uncontaminated and safe for consumption by preventing the leaching of harmful substances from the pipeline material. Other areas where these coatings are used include wastewater treatment plants, where they protect pipelines from the corrosive effects of sewage and other waste materials. The coatings also find applications in the transportation of agricultural products, where they help maintain the quality and safety of the transported goods. The versatility and effectiveness of atmospheric pipeline coatings make them indispensable in various sectors, contributing to the overall efficiency and safety of pipeline infrastructure.

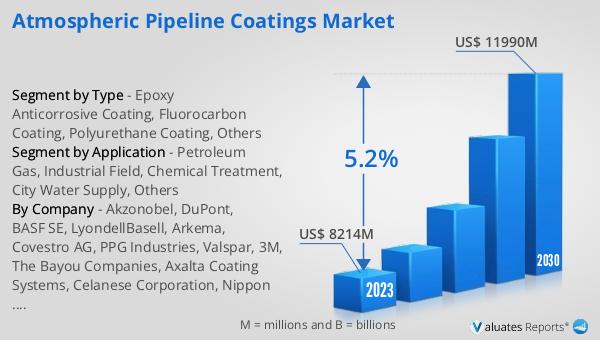

Global Atmospheric Pipeline Coatings Market Outlook:

The global Atmospheric Pipeline Coatings market was valued at US$ 8214 million in 2023 and is anticipated to reach US$ 11990 million by 2030, witnessing a CAGR of 5.2% during the forecast period 2024-2030. This significant growth reflects the increasing demand for reliable and durable pipeline infrastructure across various industries. The market's expansion is driven by the need to protect pipelines from environmental factors that can lead to corrosion and degradation. As industries continue to grow and the demand for energy and resources rises, the importance of maintaining the integrity of pipeline systems becomes paramount. Companies in the market are focusing on developing advanced coating solutions that offer enhanced protection and meet stringent regulatory standards. The projected growth also highlights the ongoing investments in research and development to create innovative coatings that can withstand harsh environmental conditions and extend the lifespan of pipelines. The market's positive outlook is a testament to the critical role that atmospheric pipeline coatings play in ensuring the safe and efficient transport of materials across various sectors.

| Report Metric | Details |

| Report Name | Atmospheric Pipeline Coatings Market |

| Accounted market size in 2023 | US$ 8214 million |

| Forecasted market size in 2030 | US$ 11990 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Akzonobel, DuPont, BASF SE, LyondellBasell, Arkema, Covestro AG, PPG Industries, Valspar, 3M, The Bayou Companies, Axalta Coating Systems, Celanese Corporation, Nippon Paint, Sherwin-Williams, KCC Corporation, Jotun Powder Coatings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |