What is Global Petroleum Asphalt Market?

The Global Petroleum Asphalt Market is a significant segment of the broader petroleum industry, focusing on the production and distribution of asphalt derived from crude oil. This market is crucial for various construction and industrial applications, primarily due to asphalt's binding and waterproofing properties. Petroleum asphalt is a byproduct of the oil refining process, where crude oil is distilled to separate lighter hydrocarbons, leaving behind a dense, sticky substance. This material is then processed to produce different grades of asphalt suitable for various uses. The global demand for petroleum asphalt is driven by infrastructure development, road construction, and maintenance activities, as well as its application in roofing and other industrial sectors. The market is characterized by a diverse range of products, including paving asphalt, roofing asphalt, and industrial asphalt, each tailored to specific needs. As urbanization and industrialization continue to rise, the demand for petroleum asphalt is expected to grow, making it a vital component of modern infrastructure projects worldwide. The market is also influenced by factors such as crude oil prices, technological advancements in production processes, and environmental regulations aimed at reducing emissions and promoting sustainable practices.

Paving Petroleum Asphalt, Industrial Petroleum Asphalt in the Global Petroleum Asphalt Market:

Paving Petroleum Asphalt is a critical component of the Global Petroleum Asphalt Market, primarily used in the construction and maintenance of roads, highways, and other paved surfaces. This type of asphalt is valued for its durability, flexibility, and ability to withstand varying weather conditions, making it an ideal choice for road construction. The production of paving asphalt involves refining crude oil to produce a material that can be mixed with aggregates to form asphalt concrete, which is then laid and compacted to create smooth, durable road surfaces. The demand for paving asphalt is driven by the need for new road infrastructure, as well as the maintenance and repair of existing roads. As urban areas expand and transportation networks grow, the requirement for high-quality paving materials continues to rise. Industrial Petroleum Asphalt, on the other hand, is used in a variety of non-paving applications, including roofing, waterproofing, and industrial coatings. This type of asphalt is prized for its adhesive and waterproofing properties, making it suitable for protecting buildings and structures from water damage. In the roofing industry, petroleum asphalt is used to produce shingles and other roofing materials that provide a durable, weather-resistant barrier. Additionally, industrial asphalt is used in the production of sealants, adhesives, and coatings for a range of applications, from protecting pipelines to coating industrial equipment. The versatility of petroleum asphalt makes it an essential material in both construction and industrial sectors, with its demand closely tied to economic growth and infrastructure development. As the global economy continues to expand, the need for high-quality asphalt products is expected to increase, driving innovation and investment in the petroleum asphalt market.

Paving, Roofing, Other in the Global Petroleum Asphalt Market:

The usage of Global Petroleum Asphalt Market products spans several key areas, including paving, roofing, and other industrial applications. In the paving sector, petroleum asphalt is primarily used to construct and maintain roads, highways, and airport runways. Its ability to provide a smooth, durable surface that can withstand heavy traffic and harsh weather conditions makes it an indispensable material for transportation infrastructure. The process of paving involves mixing asphalt with aggregates to create asphalt concrete, which is then laid and compacted to form a solid, long-lasting surface. This application is crucial for supporting economic growth and connectivity, as well-maintained roads facilitate the efficient movement of goods and people. In the roofing industry, petroleum asphalt is used to manufacture shingles, roll roofing, and other materials that provide a protective barrier against the elements. Asphalt's waterproofing properties make it an ideal choice for roofing applications, as it helps prevent water infiltration and damage to buildings. Additionally, asphalt roofing materials are known for their durability and resistance to extreme weather conditions, making them a popular choice for both residential and commercial buildings. Beyond paving and roofing, petroleum asphalt is also used in various industrial applications, such as waterproofing, sealing, and coating. Its adhesive properties make it suitable for use in sealants and adhesives, while its waterproofing capabilities are utilized in the production of coatings for pipelines, tanks, and other industrial equipment. These applications help protect structures and equipment from corrosion and environmental damage, extending their lifespan and reducing maintenance costs. The versatility of petroleum asphalt makes it a valuable material across multiple industries, with its demand driven by ongoing infrastructure development and industrial growth. As the global economy continues to expand, the need for high-quality asphalt products is expected to rise, supporting the continued growth of the Global Petroleum Asphalt Market.

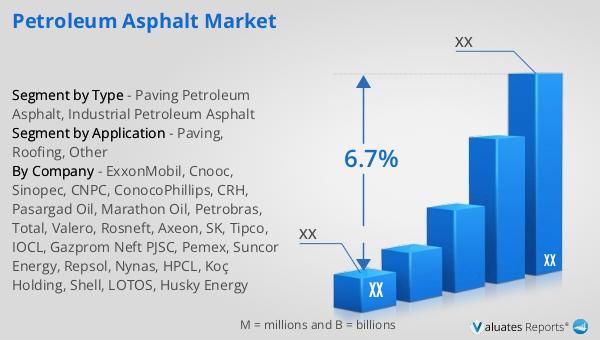

Global Petroleum Asphalt Market Outlook:

In 2024, the global market size of Petroleum Asphalt was valued at approximately US$ 75,910 million, with projections indicating it could reach around US$ 118,770 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2025 to 2031. The market is characterized by a concentration of leading manufacturers, with the top five companies holding a combined market share of about 30%. North America emerges as the largest regional market, accounting for roughly 30% of the global share, followed closely by China, which holds approximately 20%. This distribution highlights the significant role these regions play in the global petroleum asphalt industry, driven by robust infrastructure development and industrial activities. The market's expansion is fueled by increasing demand for durable and sustainable construction materials, as well as advancements in asphalt production technologies. As urbanization and industrialization continue to accelerate worldwide, the need for high-quality petroleum asphalt products is expected to grow, supporting the market's positive outlook. The strategic positioning of key manufacturers and the ongoing development of innovative asphalt solutions are likely to further enhance the market's growth prospects in the coming years.

| Report Metric | Details |

| Report Name | Petroleum Asphalt Market |

| CAGR | 6.7% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ExxonMobil, Cnooc, Sinopec, CNPC, ConocoPhillips, CRH, Pasargad Oil, Marathon Oil, Petrobras, Total, Valero, Rosneft, Axeon, SK, Tipco, IOCL, Gazprom Neft PJSC, Pemex, Suncor Energy, Repsol, Nynas, HPCL, Koç Holding, Shell, LOTOS, Husky Energy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |