What is Global SMA Actuator for Smartphone Market?

The Global SMA Actuator for Smartphone Market refers to the worldwide industry focused on the production and application of Shape Memory Alloy (SMA) actuators specifically designed for smartphones. SMA actuators are devices that use the unique properties of shape memory alloys, which can return to a pre-defined shape when heated. In the context of smartphones, these actuators are used to perform various functions such as adjusting camera lenses, providing haptic feedback, or enabling other mechanical movements within the device. The market encompasses a range of activities including research and development, manufacturing, and distribution of these actuators. It is driven by the increasing demand for advanced smartphone features and the need for compact, efficient components that can enhance device functionality without compromising on space or energy consumption. As smartphones continue to evolve with more sophisticated features, the demand for innovative SMA actuators is expected to grow, making this market a critical component of the broader smartphone industry. The market's growth is influenced by technological advancements, consumer preferences, and the competitive landscape among smartphone manufacturers seeking to differentiate their products with unique capabilities.

4-wire Actuator, 8-wire Actuator in the Global SMA Actuator for Smartphone Market:

In the Global SMA Actuator for Smartphone Market, 4-wire and 8-wire actuators represent two distinct types of SMA actuators used in smartphones, each with its own set of characteristics and applications. A 4-wire actuator typically consists of four electrical connections that facilitate the control and operation of the actuator. These actuators are often used in applications where precise control and feedback are required, such as in camera modules for autofocus or image stabilization. The four wires allow for a more complex control system, enabling the actuator to perform more sophisticated movements or adjustments. This can be particularly beneficial in smartphones where space is limited, and components need to be as efficient as possible. On the other hand, an 8-wire actuator includes eight electrical connections, which can provide even greater control and functionality. These actuators are used in more advanced applications where multiple functions need to be controlled simultaneously or where higher precision is required. The additional wires allow for more complex circuitry and control mechanisms, making them suitable for high-end smartphones with advanced features. The choice between 4-wire and 8-wire actuators depends on the specific requirements of the smartphone design, including factors such as space constraints, power consumption, and the desired functionality. Both types of actuators play a crucial role in enhancing the performance and capabilities of smartphones, contributing to the overall user experience. As the demand for more advanced smartphone features continues to grow, the development and application of both 4-wire and 8-wire actuators are expected to expand, offering new possibilities for innovation in the smartphone industry.

Smartphone, Camera, Others in the Global SMA Actuator for Smartphone Market:

The usage of Global SMA Actuator for Smartphone Market extends across various areas, including smartphones, cameras, and other applications. In smartphones, SMA actuators are primarily used to enhance the functionality and user experience by enabling features such as haptic feedback, camera autofocus, and image stabilization. These actuators allow for precise control of mechanical movements within the device, which is essential for delivering high-quality performance in a compact form factor. For instance, in camera modules, SMA actuators can adjust the lens position to achieve sharp focus or compensate for hand movements to reduce blurriness in photos and videos. This capability is particularly important as smartphone cameras become more advanced and are expected to deliver professional-grade results. Beyond cameras, SMA actuators can also be used in other smartphone components, such as speakers or vibration motors, to provide tactile feedback or enhance audio quality. In addition to smartphones, SMA actuators find applications in other areas where compact and efficient actuation is required. For example, they can be used in wearable devices, medical equipment, or consumer electronics to perform precise mechanical movements without adding significant bulk or weight. The versatility and efficiency of SMA actuators make them an attractive choice for a wide range of applications, driving their adoption across various industries. As technology continues to advance, the potential uses for SMA actuators are likely to expand, offering new opportunities for innovation and development in the Global SMA Actuator for Smartphone Market.

Global SMA Actuator for Smartphone Market Outlook:

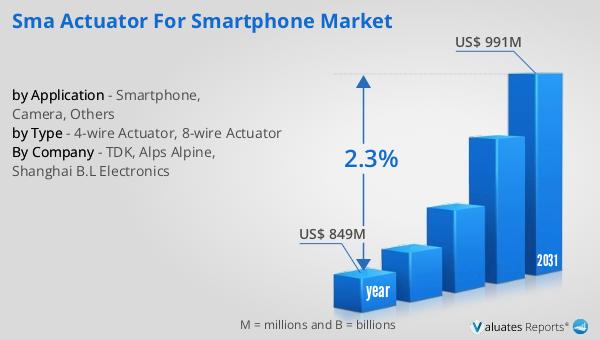

The global market for SMA Actuator for Smartphones was valued at $849 million in 2024 and is anticipated to grow to a revised size of $991 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period. This growth trajectory highlights the increasing demand for SMA actuators in the smartphone industry, driven by the need for more advanced and efficient components that can enhance device functionality. The steady growth rate indicates a stable market environment, where technological advancements and consumer preferences continue to shape the demand for innovative solutions. As smartphones evolve with more sophisticated features, the role of SMA actuators becomes increasingly important, offering manufacturers the ability to differentiate their products with unique capabilities. The projected market size underscores the significance of SMA actuators in the broader smartphone industry, as manufacturers seek to integrate these components to improve performance and user experience. The market outlook reflects the ongoing trends and developments in the industry, providing insights into the future potential of SMA actuators in the global market.

| Report Metric | Details |

| Report Name | SMA Actuator for Smartphone Market |

| Accounted market size in year | US$ 849 million |

| Forecasted market size in 2031 | US$ 991 million |

| CAGR | 2.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TDK, Alps Alpine, Shanghai B.L Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |