What is Global Single-Acting Aluminium Cylinder Market?

The Global Single-Acting Aluminium Cylinder Market refers to the worldwide industry focused on the production, distribution, and application of single-acting aluminium cylinders. These cylinders are mechanical devices that use the pressure of a fluid, typically hydraulic oil, to produce a linear force and motion. Unlike double-acting cylinders, which can exert force in both directions, single-acting cylinders apply force in only one direction, with a spring or external force returning the piston to its original position. Aluminium is favored in these cylinders due to its lightweight nature, corrosion resistance, and excellent strength-to-weight ratio, making it ideal for various industrial applications. The market encompasses a wide range of industries, including construction, manufacturing, and automotive, where these cylinders are used for lifting, pushing, pulling, and other mechanical tasks. The demand for these cylinders is driven by their efficiency, durability, and the growing need for automation and mechanization in various sectors. As industries continue to evolve and seek more efficient and sustainable solutions, the Global Single-Acting Aluminium Cylinder Market is expected to expand, offering innovative products and technologies to meet diverse industrial needs.

Below 50 Ton, 50 to 100 Ton, Above 100 Ton in the Global Single-Acting Aluminium Cylinder Market:

In the Global Single-Acting Aluminium Cylinder Market, the classification based on capacity is crucial for understanding the diverse applications and demands across different industries. The market is segmented into three primary categories: Below 50 Ton, 50 to 100 Ton, and Above 100 Ton. Each category serves distinct purposes and industries, catering to specific needs based on the required force and application environment. Cylinders with a capacity Below 50 Ton are typically used in applications where lighter loads are involved. These cylinders are ideal for tasks that require precision and control, such as in automotive repair shops for lifting vehicles, in small-scale manufacturing units for assembly line operations, and in agricultural machinery for various tasks. Their lightweight nature and ease of handling make them suitable for portable applications, where mobility and flexibility are essential. The 50 to 100 Ton category represents a mid-range capacity that balances power and versatility. These cylinders are commonly used in construction and infrastructure projects, where moderate lifting and pushing tasks are required. They are also prevalent in industrial settings, such as in machinery maintenance and equipment installation, where a balance between power and maneuverability is necessary. The robust construction of these cylinders ensures durability and reliability, even in demanding environments. Above 100 Ton cylinders are designed for heavy-duty applications, where significant force is required. These cylinders are essential in industries such as mining, shipbuilding, and large-scale construction, where lifting and moving massive structures or materials is a routine task. Their high capacity allows them to handle the most challenging jobs, providing the necessary power to perform tasks that would be impossible with lower-capacity cylinders. The construction of these cylinders is focused on strength and durability, ensuring they can withstand the harshest conditions and deliver consistent performance. The segmentation of the Global Single-Acting Aluminium Cylinder Market based on capacity highlights the diverse needs of various industries and the importance of selecting the right cylinder for specific applications. Each category offers unique advantages, and understanding these can help businesses make informed decisions when investing in hydraulic solutions. As industries continue to grow and evolve, the demand for these cylinders is expected to increase, driven by the need for efficient, reliable, and powerful hydraulic systems.

Shipyard, Steel Mill, Energy, Industrial, Infrastructure, Mining, Oil and Gas in the Global Single-Acting Aluminium Cylinder Market:

The Global Single-Acting Aluminium Cylinder Market finds extensive usage across various industries, each with unique requirements and applications. In shipyards, these cylinders are indispensable for tasks such as lifting and positioning heavy ship components, facilitating repairs, and assisting in the construction of new vessels. Their lightweight nature and corrosion resistance make them ideal for the harsh marine environment, where durability and reliability are paramount. In steel mills, single-acting aluminium cylinders are used for tasks such as rolling, pressing, and shaping steel products. Their ability to exert significant force in a controlled manner makes them essential for maintaining precision and efficiency in steel production processes. The energy sector also benefits from these cylinders, particularly in renewable energy installations such as wind and solar farms. They are used for positioning and maintaining equipment, ensuring optimal performance and efficiency. In industrial settings, single-acting aluminium cylinders are employed in a wide range of applications, from assembly line operations to machinery maintenance. Their versatility and ease of use make them a valuable tool for improving productivity and reducing downtime. Infrastructure projects, such as bridge construction and road maintenance, also rely on these cylinders for tasks such as lifting and positioning heavy materials, ensuring safety and efficiency in construction operations. In the mining industry, the robust construction and high capacity of these cylinders make them ideal for tasks such as ore extraction and equipment maintenance. Their ability to withstand harsh conditions and deliver consistent performance is crucial in this demanding environment. Finally, in the oil and gas sector, single-acting aluminium cylinders are used for tasks such as pipeline maintenance, equipment installation, and offshore drilling operations. Their corrosion resistance and reliability make them a preferred choice in this industry, where safety and efficiency are critical. The diverse applications of single-acting aluminium cylinders across these industries highlight their importance in modern industrial operations. As technology advances and industries continue to seek more efficient and sustainable solutions, the demand for these cylinders is expected to grow, driving innovation and development in the Global Single-Acting Aluminium Cylinder Market.

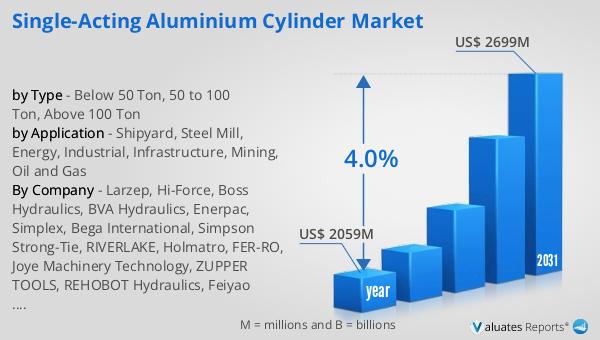

Global Single-Acting Aluminium Cylinder Market Outlook:

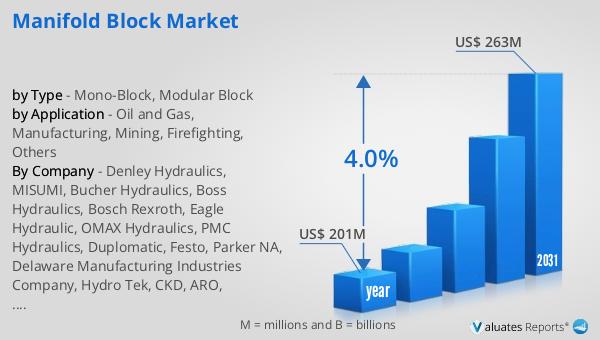

The outlook for the Global Single-Acting Aluminium Cylinder Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 2059 million. Projections suggest that by 2031, this figure will rise to an estimated US$ 2699 million, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This growth is driven by several factors, including the increasing demand for efficient and reliable hydraulic solutions across various industries. As sectors such as construction, manufacturing, and energy continue to expand, the need for robust and versatile cylinders is expected to rise. The lightweight and corrosion-resistant properties of aluminium make these cylinders particularly attractive, offering a balance of strength and durability that is essential for modern industrial applications. Additionally, the ongoing trend towards automation and mechanization in industries further fuels the demand for single-acting aluminium cylinders, as they play a crucial role in enhancing operational efficiency and productivity. As the market continues to evolve, manufacturers are likely to focus on innovation and the development of advanced products to meet the changing needs of their customers. This dynamic environment presents opportunities for growth and expansion, positioning the Global Single-Acting Aluminium Cylinder Market as a key player in the global industrial landscape.

| Report Metric | Details |

| Report Name | Single-Acting Aluminium Cylinder Market |

| Accounted market size in year | US$ 2059 million |

| Forecasted market size in 2031 | US$ 2699 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Larzep, Hi-Force, Boss Hydraulics, BVA Hydraulics, Enerpac, Simplex, Bega International, Simpson Strong-Tie, RIVERLAKE, Holmatro, FER-RO, Joye Machinery Technology, ZUPPER TOOLS, REHOBOT Hydraulics, Feiyao Machinery, Freedom Industrial Hydraulics, ZIPP TOOL, Uphyd, SVI International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |