What is Global Manifold Block Market?

The Global Manifold Block Market is a crucial segment within the industrial and engineering sectors, serving as a pivotal component in fluid control systems. Manifold blocks are integral in directing and controlling the flow of fluids, such as oil, gas, and water, within various machinery and equipment. These blocks are essentially a series of valves and channels that allow for the efficient distribution and regulation of fluids, ensuring optimal performance and safety in operations. They are widely used in industries like oil and gas, manufacturing, mining, and firefighting, where precise fluid control is essential. The market for manifold blocks is driven by the increasing demand for efficient and reliable fluid control systems, as well as the need for advanced technology to enhance operational efficiency. As industries continue to evolve and expand, the demand for manifold blocks is expected to grow, making it a vital component in the global industrial landscape. The manifold block market is characterized by a diverse range of products, including mono-block and modular block designs, each offering unique advantages and applications. As technology advances, the market is likely to see further innovations and developments, catering to the ever-changing needs of various industries.

Mono-Block, Modular Block in the Global Manifold Block Market:

Mono-block and modular block designs are two primary types of manifold blocks that cater to different industrial needs within the Global Manifold Block Market. Mono-block manifolds are typically a single, solid piece of metal with integrated channels and valves. This design offers several advantages, including compactness, reduced potential for leaks, and ease of installation. The mono-block design is particularly favored in applications where space is limited, and reliability is paramount. Its robust construction ensures durability and long-term performance, making it ideal for high-pressure environments such as oil and gas extraction and processing. On the other hand, modular block manifolds consist of multiple interconnected sections or modules, allowing for greater flexibility and customization. This design is advantageous in applications where system requirements may change over time, as it allows for easy modification and expansion. Modular blocks are often used in manufacturing and industrial automation, where the ability to adapt to changing production needs is crucial. The modular design also facilitates maintenance and repair, as individual sections can be replaced or upgraded without disrupting the entire system. Both mono-block and modular block designs play a significant role in the manifold block market, offering solutions tailored to specific industry requirements. As industries continue to seek more efficient and adaptable fluid control systems, the demand for both mono-block and modular block designs is expected to grow. The choice between these two designs often depends on factors such as the specific application, space constraints, and the need for customization. In summary, mono-block and modular block designs each offer unique benefits and are essential components of the Global Manifold Block Market, catering to the diverse needs of various industries.

Oil and Gas, Manufacturing, Mining, Firefighting, Others in the Global Manifold Block Market:

The Global Manifold Block Market finds extensive usage across several key industries, including oil and gas, manufacturing, mining, firefighting, and others. In the oil and gas industry, manifold blocks are critical for controlling the flow of oil and gas during extraction, processing, and transportation. They ensure the safe and efficient operation of equipment, preventing leaks and minimizing downtime. The ability to withstand high pressures and harsh environmental conditions makes manifold blocks indispensable in this sector. In manufacturing, manifold blocks are used to regulate the flow of fluids in automated machinery and production lines. They help maintain precise control over processes, ensuring product quality and consistency. The modular design of manifold blocks is particularly beneficial in manufacturing, allowing for easy adaptation to changing production needs. In the mining industry, manifold blocks are used to control the flow of hydraulic fluids in heavy machinery and equipment. They play a crucial role in ensuring the safe and efficient operation of mining equipment, reducing the risk of accidents and equipment failure. Firefighting applications also rely on manifold blocks to control the flow of water and firefighting foam. They enable firefighters to direct resources effectively, enhancing their ability to combat fires and protect lives and property. Beyond these industries, manifold blocks are used in various other applications, such as water treatment, chemical processing, and HVAC systems. Their versatility and reliability make them a valuable component in any system requiring precise fluid control. As industries continue to evolve and face new challenges, the demand for advanced manifold block solutions is expected to grow, driving innovation and development in the market.

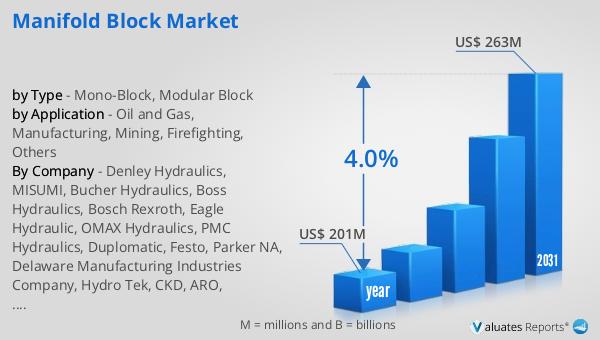

Global Manifold Block Market Outlook:

In 2024, the global market for manifold blocks was valued at approximately $201 million. This market is anticipated to expand significantly, reaching an estimated value of $263 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.0% over the forecast period. The steady increase in market size reflects the rising demand for efficient and reliable fluid control systems across various industries. As industries such as oil and gas, manufacturing, and mining continue to expand and modernize, the need for advanced manifold block solutions becomes increasingly critical. The market's growth is also driven by technological advancements and innovations in manifold block design, which enhance performance and adaptability. The increasing focus on operational efficiency and safety further fuels the demand for manifold blocks, as they play a vital role in ensuring the smooth and safe operation of equipment and machinery. As the market continues to evolve, it is expected to see further developments and innovations, catering to the diverse needs of industries worldwide. The projected growth of the manifold block market underscores its importance as a key component in the global industrial landscape, driving efficiency and reliability in fluid control systems.

| Report Metric | Details |

| Report Name | Manifold Block Market |

| Accounted market size in year | US$ 201 million |

| Forecasted market size in 2031 | US$ 263 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Denley Hydraulics, MISUMI, Bucher Hydraulics, Boss Hydraulics, Bosch Rexroth, Eagle Hydraulic, OMAX Hydraulics, PMC Hydraulics, Duplomatic, Festo, Parker NA, Delaware Manufacturing Industries Company, Hydro Tek, CKD, ARO, KawarthaControls, DAIKIN INDUSTRIES, Sun Hydraulics, Kirby Morgan, Target Hydraulics, Honeywell, Dixon Valve & Coupling, Alemite, EMI, Kosmek, Lincoln Industrial, Metalsub |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |