What is Global Car Sensor Market?

The Global Car Sensor Market is a rapidly evolving sector within the automotive industry, driven by the increasing demand for advanced safety features, fuel efficiency, and enhanced vehicle performance. Car sensors are integral components that collect data from various parts of a vehicle, enabling systems to monitor and optimize performance. These sensors play a crucial role in ensuring the safety and efficiency of modern vehicles by providing real-time information to the vehicle's control systems. The market encompasses a wide range of sensors, including pressure, temperature, speed, and position sensors, each serving specific functions within a vehicle. As automotive technology continues to advance, the demand for sophisticated sensors is expected to grow, driven by the rise of electric vehicles, autonomous driving technologies, and stringent emission regulations. The Global Car Sensor Market is characterized by continuous innovation and development, with manufacturers focusing on creating more accurate, reliable, and cost-effective sensor solutions. This market is poised for significant growth as the automotive industry shifts towards more intelligent and connected vehicles, making sensors an indispensable component of modern automotive design and functionality.

Pressure Sensor, Temperature Sensor, Speed Sensor, Position Sensor, Other in the Global Car Sensor Market:

Pressure sensors in the Global Car Sensor Market are vital for monitoring and managing various vehicle systems. They measure the pressure of gases or liquids within the vehicle, ensuring optimal performance and safety. For instance, tire pressure sensors alert drivers when tire pressure is low, preventing accidents and improving fuel efficiency. Similarly, pressure sensors in the engine monitor oil and fuel pressure, ensuring the engine runs smoothly and efficiently. Temperature sensors, on the other hand, are crucial for maintaining the vehicle's thermal balance. They monitor the temperature of the engine, transmission, and other critical components, preventing overheating and ensuring optimal performance. These sensors help in maintaining the right temperature for the catalytic converter, which is essential for reducing emissions. Speed sensors are another critical component, providing data on the vehicle's speed to various systems, including the anti-lock braking system (ABS) and electronic stability control (ESC). These sensors help in maintaining vehicle stability and safety by preventing wheel lockup during sudden braking and ensuring optimal traction. Position sensors, such as throttle position sensors and crankshaft position sensors, provide data on the position of various components, ensuring precise control of the engine and transmission. These sensors are essential for optimizing fuel efficiency and reducing emissions. Other sensors in the Global Car Sensor Market include oxygen sensors, which monitor the level of oxygen in the exhaust gases, helping to optimize the air-fuel mixture for better combustion and reduced emissions. Knock sensors detect engine knocking, allowing the engine control unit to adjust the ignition timing and prevent damage. As vehicles become more advanced, the demand for these sensors is expected to grow, driven by the need for improved safety, efficiency, and performance. The integration of these sensors into vehicle systems is crucial for the development of autonomous and electric vehicles, which rely heavily on accurate and reliable sensor data to operate safely and efficiently. The Global Car Sensor Market is thus a dynamic and rapidly evolving sector, with continuous advancements in sensor technology driving the development of more intelligent and connected vehicles.

Passenger Vehicle, Commercial Vehicle in the Global Car Sensor Market:

The usage of sensors in the Global Car Sensor Market is pivotal for both passenger and commercial vehicles, enhancing safety, efficiency, and overall performance. In passenger vehicles, sensors are primarily used to improve safety and comfort. For instance, advanced driver-assistance systems (ADAS) rely heavily on sensors to provide features such as adaptive cruise control, lane departure warning, and automatic emergency braking. These systems use data from various sensors, including radar, lidar, and cameras, to monitor the vehicle's surroundings and assist the driver in making informed decisions. Temperature and pressure sensors are also crucial in passenger vehicles, ensuring the engine and other critical components operate within optimal parameters, thereby enhancing fuel efficiency and reducing emissions. In commercial vehicles, sensors play a vital role in fleet management and logistics. They provide real-time data on vehicle performance, enabling fleet managers to monitor and optimize fuel consumption, maintenance schedules, and route planning. Speed and position sensors are particularly important in commercial vehicles, ensuring compliance with safety regulations and improving operational efficiency. Additionally, sensors in commercial vehicles help in monitoring cargo conditions, such as temperature and humidity, ensuring the safe and efficient transport of goods. The integration of sensors in both passenger and commercial vehicles is essential for the development of autonomous and electric vehicles, which rely on accurate and reliable sensor data to operate safely and efficiently. As the automotive industry continues to evolve, the demand for advanced sensor technologies is expected to grow, driven by the need for improved safety, efficiency, and performance in both passenger and commercial vehicles. The Global Car Sensor Market is thus a dynamic and rapidly evolving sector, with continuous advancements in sensor technology driving the development of more intelligent and connected vehicles.

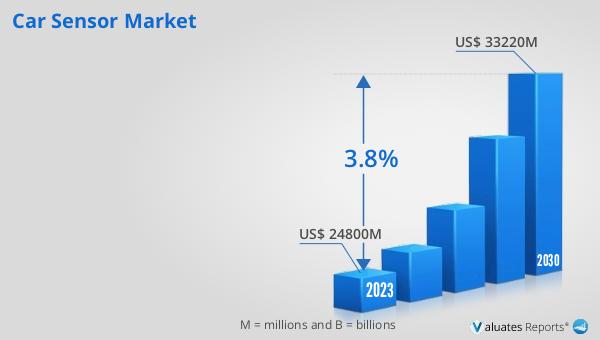

Global Car Sensor Market Outlook:

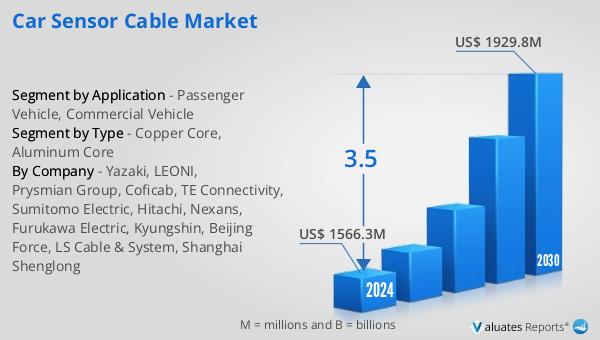

The outlook for the Global Car Sensor Market indicates a promising growth trajectory, with the market expected to expand from $26,560 million in 2024 to $33,220 million by 2030. This growth is projected at a compound annual growth rate (CAGR) of 3.8% during the forecast period. This anticipated growth is driven by several factors, including the increasing demand for advanced safety features, the rise of electric and autonomous vehicles, and stringent emission regulations. As automotive technology continues to advance, the need for sophisticated sensors that can provide accurate and reliable data is becoming increasingly important. Manufacturers are focusing on developing innovative sensor solutions that are not only more accurate and reliable but also cost-effective. The integration of sensors into vehicle systems is crucial for the development of more intelligent and connected vehicles, which are expected to dominate the automotive market in the coming years. The Global Car Sensor Market is thus poised for significant growth, driven by the continuous advancements in sensor technology and the increasing demand for more intelligent and connected vehicles. As the market continues to evolve, manufacturers and suppliers will need to stay ahead of the curve by investing in research and development to create more advanced and reliable sensor solutions that meet the needs of the modern automotive industry.

| Report Metric | Details |

| Report Name | Car Sensor Market |

| Accounted market size in 2024 | US$ 26560 million |

| Forecasted market size in 2030 | US$ 33220 million |

| CAGR | 3.8 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Robert Bosch, Continental, DENSO, Analog Devices, Sensata Technologies, Delphi, Infineon Technologies, STMicroelectronics, Valeo, Hitachi, Autoliv, Mobis, ZF, NXP Semiconductors, Bourns |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |