What is Global Vehicle Sensor Cable Market?

The Global Vehicle Sensor Cable Market is a crucial segment within the automotive industry, focusing on the development and distribution of cables that connect various sensors in vehicles. These sensor cables are integral to the functioning of modern vehicles, as they transmit data from sensors to the vehicle's electronic control units (ECUs). This data is essential for monitoring and controlling various vehicle functions, such as engine performance, emissions, safety systems, and driver assistance features. The market for vehicle sensor cables is driven by the increasing demand for advanced safety features, the rise of electric and hybrid vehicles, and the growing trend of vehicle automation. As vehicles become more sophisticated, the need for reliable and efficient sensor cables becomes more pronounced. These cables must withstand harsh environmental conditions, such as extreme temperatures, vibrations, and exposure to chemicals, while maintaining high levels of performance and durability. The global market is characterized by a diverse range of products, catering to different vehicle types and applications, and is supported by ongoing advancements in sensor and cable technology.

Copper Core, Aluminum Core in the Global Vehicle Sensor Cable Market:

In the Global Vehicle Sensor Cable Market, copper core and aluminum core cables are two primary types of materials used in the manufacturing of these essential components. Copper core cables have long been the standard in the industry due to their excellent electrical conductivity, flexibility, and durability. Copper's ability to efficiently transmit electrical signals makes it ideal for use in sensor cables, where precise data transmission is critical. Additionally, copper's flexibility allows for easy installation in the complex wiring systems of modern vehicles. However, copper is relatively heavy and expensive, which has led to the exploration of alternative materials. Aluminum core cables have emerged as a viable alternative, offering several advantages over copper. Aluminum is significantly lighter than copper, which can contribute to overall vehicle weight reduction, an important factor in improving fuel efficiency and reducing emissions. Moreover, aluminum is generally less expensive than copper, making it an attractive option for manufacturers looking to reduce costs. Despite these benefits, aluminum core cables have some limitations. They are not as conductive as copper, which can affect the performance of the sensor system. To address this, manufacturers often use larger diameter aluminum cables to achieve similar conductivity levels, which can offset some of the weight savings. Additionally, aluminum is less flexible than copper, which can pose challenges during installation. The choice between copper and aluminum core cables often depends on the specific requirements of the vehicle and the priorities of the manufacturer, such as cost, weight, and performance. In recent years, there has been a growing trend towards the use of hybrid cables, which combine both copper and aluminum cores to leverage the advantages of both materials. These hybrid cables aim to provide a balance between conductivity, weight, and cost, offering a versatile solution for the diverse needs of the automotive industry. As the Global Vehicle Sensor Cable Market continues to evolve, the development of new materials and technologies will likely play a significant role in shaping the future of sensor cable design and application.

Passenger Vehicle, Commercial Vehicle in the Global Vehicle Sensor Cable Market:

The usage of Global Vehicle Sensor Cable Market products is extensive in both passenger and commercial vehicles, each with its unique set of requirements and applications. In passenger vehicles, sensor cables are crucial for a wide range of functions, from basic operations to advanced driver assistance systems (ADAS). These cables connect sensors that monitor engine performance, fuel efficiency, and emissions, ensuring that the vehicle operates smoothly and meets regulatory standards. Additionally, sensor cables are integral to safety systems, such as airbags, anti-lock braking systems (ABS), and electronic stability control (ESC), which rely on accurate and timely data to function effectively. As passenger vehicles become increasingly equipped with ADAS features, such as adaptive cruise control, lane departure warning, and automatic emergency braking, the demand for high-quality sensor cables continues to grow. These systems require precise data transmission to ensure the safety and comfort of the driver and passengers. In commercial vehicles, the role of sensor cables is equally important, though the focus may differ slightly. Commercial vehicles, such as trucks and buses, often operate under more demanding conditions and require robust sensor systems to ensure reliability and efficiency. Sensor cables in commercial vehicles are used to monitor engine health, fuel consumption, and emissions, as well as to support advanced telematics systems that provide real-time data on vehicle location, speed, and performance. These systems are essential for fleet management, helping operators optimize routes, reduce fuel costs, and improve overall operational efficiency. Furthermore, as the commercial vehicle sector increasingly adopts electric and hybrid technologies, the need for specialized sensor cables that can handle high voltages and currents becomes more critical. In both passenger and commercial vehicles, the Global Vehicle Sensor Cable Market plays a vital role in supporting the ongoing advancements in vehicle technology, contributing to improved safety, efficiency, and sustainability.

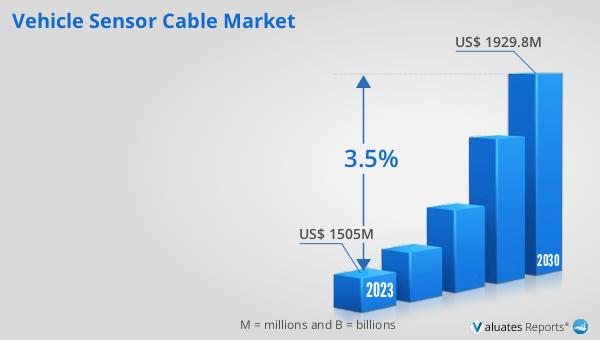

Global Vehicle Sensor Cable Market Outlook:

The outlook for the Global Vehicle Sensor Cable Market indicates a steady growth trajectory over the coming years. The market is expected to expand from a valuation of approximately US$ 1566.3 million in 2024 to around US$ 1929.8 million by 2030. This growth is projected to occur at a Compound Annual Growth Rate (CAGR) of 3.5% during the forecast period. This anticipated growth can be attributed to several factors, including the increasing demand for advanced vehicle technologies, the rise of electric and hybrid vehicles, and the ongoing emphasis on vehicle safety and efficiency. As automotive manufacturers continue to innovate and integrate more sophisticated systems into their vehicles, the need for reliable and efficient sensor cables will become even more pronounced. The market's expansion is also likely to be supported by advancements in sensor and cable technology, which will enable the development of more durable, efficient, and cost-effective products. Additionally, the growing trend towards vehicle automation and connectivity will further drive the demand for high-quality sensor cables, as these systems rely heavily on accurate and timely data transmission. Overall, the Global Vehicle Sensor Cable Market is poised for significant growth, driven by the evolving needs of the automotive industry and the continuous advancements in technology.

| Report Metric | Details |

| Report Name | Vehicle Sensor Cable Market |

| Accounted market size in 2024 | US$ 1566.3 million |

| Forecasted market size in 2030 | US$ 1929.8 million |

| CAGR | 3.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Yazaki, LEONI, Prysmian Group, Coficab, TE Connectivity, Sumitomo Electric, Hitachi, Nexans, Furukawa Electric, Kyungshin, Beijing Force, LS Cable & System, Shanghai Shenglong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |