What is Global Automotive Sensor Cable Market?

The Global Automotive Sensor Cable Market is a crucial segment within the automotive industry, focusing on the production and distribution of sensor cables used in vehicles. These cables are integral components that connect various sensors to the vehicle's electronic control units (ECUs), enabling the transmission of data necessary for the optimal functioning of the vehicle. As vehicles become more advanced with features like autonomous driving, advanced driver-assistance systems (ADAS), and enhanced infotainment systems, the demand for reliable and efficient sensor cables has increased. These cables must withstand harsh environmental conditions, such as extreme temperatures, vibrations, and exposure to chemicals, while maintaining high performance and durability. The market encompasses a wide range of cable types, including those made from different core materials like copper and aluminum, each offering distinct advantages in terms of conductivity, weight, and cost. As the automotive industry continues to evolve with technological advancements, the Global Automotive Sensor Cable Market is expected to grow, driven by the increasing need for sophisticated vehicle electronics and the push towards more sustainable and efficient transportation solutions.

Copper Core, Aluminum Core in the Global Automotive Sensor Cable Market:

In the Global Automotive Sensor Cable Market, the choice between copper core and aluminum core cables is significant, as each material offers unique benefits and challenges. Copper core cables are traditionally favored for their excellent electrical conductivity, which ensures efficient data transmission between sensors and the vehicle's electronic systems. Copper's high conductivity allows for smaller cable diameters, which can be advantageous in reducing the overall weight and space occupied by the wiring harness in a vehicle. Additionally, copper is highly durable and resistant to corrosion, making it suitable for the demanding environments within an automobile. However, copper is relatively heavy and expensive, which can be a drawback in the context of modern automotive design, where weight reduction and cost efficiency are critical considerations. On the other hand, aluminum core cables present a viable alternative due to their lightweight nature and lower cost compared to copper. Aluminum is approximately one-third the weight of copper, which can significantly contribute to reducing the overall weight of the vehicle, thereby improving fuel efficiency and reducing emissions. This aspect is particularly important as the automotive industry moves towards more environmentally friendly solutions. Moreover, aluminum is abundant and less expensive, which can lead to cost savings in the production of sensor cables. However, aluminum's electrical conductivity is lower than that of copper, which means that aluminum cables typically need to be larger in diameter to achieve the same level of conductivity. This can pose challenges in terms of space and flexibility within the vehicle's wiring system. Despite these challenges, advancements in material technology and engineering have led to the development of aluminum alloys and improved manufacturing techniques that enhance the performance of aluminum core cables. These innovations aim to bridge the conductivity gap between aluminum and copper, making aluminum a more competitive option in the market. Additionally, the automotive industry's shift towards electric vehicles (EVs) and hybrid vehicles has further fueled the demand for lightweight materials, as reducing the weight of the vehicle can directly impact the range and efficiency of EVs. In this context, aluminum core cables are gaining traction as a preferred choice for manufacturers looking to optimize vehicle performance while maintaining cost-effectiveness. The decision between copper and aluminum core cables ultimately depends on the specific requirements of the vehicle and the priorities of the manufacturer. Factors such as the intended application, environmental conditions, cost constraints, and performance expectations all play a role in determining the most suitable material for sensor cables. As the Global Automotive Sensor Cable Market continues to grow and evolve, manufacturers are likely to explore hybrid solutions that combine the strengths of both copper and aluminum, leveraging the benefits of each material to meet the diverse needs of modern vehicles. This dynamic interplay between copper and aluminum core cables underscores the complexity and innovation inherent in the automotive sensor cable industry, as it strives to support the ever-advancing technological landscape of the automotive sector.

Passenger Vehicle, Commercial Vehicle in the Global Automotive Sensor Cable Market:

The usage of sensor cables in the Global Automotive Sensor Cable Market is pivotal for both passenger vehicles and commercial vehicles, each with distinct requirements and applications. In passenger vehicles, sensor cables are essential for a wide range of functions that enhance safety, comfort, and convenience for drivers and passengers. These cables connect sensors that monitor various aspects of the vehicle's performance, such as engine temperature, oil pressure, and tire pressure, providing real-time data to the vehicle's electronic control units. This data is crucial for maintaining optimal vehicle performance and ensuring the safety of the occupants. Additionally, sensor cables are integral to the operation of advanced driver-assistance systems (ADAS), which include features like adaptive cruise control, lane departure warning, and automatic emergency braking. These systems rely on accurate and timely data transmission through sensor cables to function effectively, highlighting the importance of high-quality cables in passenger vehicles. In commercial vehicles, the role of sensor cables is equally significant, albeit with a focus on different priorities. Commercial vehicles, such as trucks, buses, and delivery vans, often operate under more demanding conditions and are subject to rigorous usage patterns. As a result, the sensor cables used in these vehicles must be robust and durable, capable of withstanding harsh environments and heavy-duty operations. Sensor cables in commercial vehicles are crucial for monitoring critical parameters such as engine performance, fuel efficiency, and emissions, which are vital for maintaining operational efficiency and compliance with regulatory standards. Furthermore, the integration of telematics systems in commercial vehicles relies heavily on sensor cables to transmit data related to vehicle location, speed, and driver behavior, enabling fleet managers to optimize logistics and improve overall fleet performance. The increasing adoption of electric and hybrid vehicles in both passenger and commercial segments further underscores the importance of sensor cables. These vehicles require sophisticated electrical systems to manage battery performance, energy consumption, and regenerative braking, all of which depend on reliable sensor cables for data transmission. As the automotive industry continues to innovate and evolve, the demand for advanced sensor cables that can support the complex electronic systems in modern vehicles is expected to grow. This growth is driven by the need for enhanced vehicle performance, improved safety features, and greater energy efficiency, all of which are facilitated by the effective use of sensor cables in both passenger and commercial vehicles.

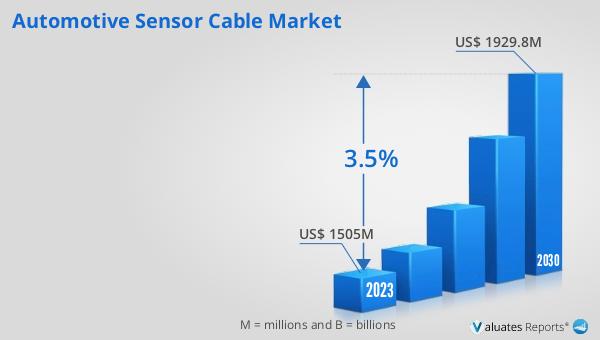

Global Automotive Sensor Cable Market Outlook:

The outlook for the Global Automotive Sensor Cable Market indicates a steady growth trajectory over the coming years. According to projections, the market is expected to expand from a valuation of approximately US$ 1566.3 million in 2024 to around US$ 1929.8 million by 2030. This growth represents a Compound Annual Growth Rate (CAGR) of 3.5% during the forecast period. This anticipated increase is driven by several factors, including the rising demand for advanced automotive technologies, the growing emphasis on vehicle safety and efficiency, and the ongoing shift towards electric and hybrid vehicles. As vehicles become more technologically sophisticated, the need for reliable and efficient sensor cables becomes increasingly critical, supporting the integration of complex electronic systems and ensuring optimal vehicle performance. The market's growth is also influenced by the automotive industry's focus on sustainability and environmental responsibility. As manufacturers strive to reduce the carbon footprint of their vehicles, the demand for lightweight and cost-effective materials, such as aluminum core cables, is expected to rise. This trend aligns with the broader industry movement towards more sustainable transportation solutions, further bolstering the market's expansion. Additionally, the increasing adoption of autonomous driving technologies and advanced driver-assistance systems (ADAS) is likely to drive the demand for high-quality sensor cables, as these systems rely heavily on accurate and timely data transmission to function effectively. Overall, the Global Automotive Sensor Cable Market is poised for growth, supported by technological advancements, evolving consumer preferences, and regulatory pressures. As the market continues to develop, manufacturers and suppliers will need to innovate and adapt to meet the changing demands of the automotive industry, ensuring the continued success and relevance of sensor cables in modern vehicles.

| Report Metric | Details |

| Report Name | Automotive Sensor Cable Market |

| Accounted market size in 2024 | US$ 1566.3 million |

| Forecasted market size in 2030 | US$ 1929.8 million |

| CAGR | 3.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Yazaki, LEONI, Prysmian Group, Coficab, TE Connectivity, Sumitomo Electric, Hitachi, Nexans, Furukawa Electric, Kyungshin, Beijing Force, LS Cable & System, Shanghai Shenglong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |