What is Global Car ABS Sensor Cable Market?

The Global Car ABS Sensor Cable Market refers to the industry focused on the production and distribution of cables used in Anti-lock Braking Systems (ABS) in vehicles. ABS is a crucial safety feature in modern vehicles, preventing the wheels from locking up during braking and thus maintaining traction with the road surface. The sensor cables are integral components of the ABS, transmitting data from the wheel speed sensors to the ABS control unit. This data helps the system modulate brake pressure to prevent skidding. The market for these cables is driven by the increasing demand for vehicle safety features, advancements in automotive technology, and the growing automotive industry worldwide. As more vehicles are equipped with ABS, the demand for reliable and efficient sensor cables continues to rise. Manufacturers are focusing on developing cables that can withstand harsh environmental conditions and provide accurate data transmission. The market is also influenced by regulatory standards mandating the inclusion of ABS in vehicles, further propelling its growth. Overall, the Global Car ABS Sensor Cable Market is a vital segment of the automotive industry, contributing to vehicle safety and performance.

Copper Core, Aluminum Core in the Global Car ABS Sensor Cable Market:

In the Global Car ABS Sensor Cable Market, two primary types of core materials are used: copper and aluminum. Copper core cables are widely preferred due to their excellent electrical conductivity, flexibility, and durability. Copper's high conductivity ensures efficient transmission of signals from the wheel speed sensors to the ABS control unit, which is crucial for the timely activation of the braking system. Additionally, copper's flexibility allows for easy installation and routing within the vehicle's complex wiring system. Its durability ensures that the cables can withstand the vibrations and temperature fluctuations experienced in automotive environments. However, copper is relatively expensive, which can increase the overall cost of the ABS sensor cables. On the other hand, aluminum core cables offer a cost-effective alternative to copper. Aluminum is lighter than copper, which can contribute to overall vehicle weight reduction, an important consideration in automotive design for improving fuel efficiency. Although aluminum has lower electrical conductivity compared to copper, advancements in cable design and manufacturing have improved its performance to meet the requirements of ABS systems. Aluminum cables are also more resistant to corrosion, which can enhance their longevity in harsh conditions. However, they are less flexible than copper cables, which can pose challenges during installation. The choice between copper and aluminum core cables depends on various factors, including cost, performance requirements, and specific vehicle design considerations. Manufacturers in the Global Car ABS Sensor Cable Market are continually innovating to improve the performance and cost-effectiveness of both copper and aluminum core cables. They are exploring new materials and technologies to enhance conductivity, flexibility, and durability while reducing weight and cost. This ongoing innovation is crucial to meet the evolving demands of the automotive industry and ensure the safety and reliability of ABS systems. As the market continues to grow, the competition between copper and aluminum core cables is likely to intensify, driving further advancements in cable technology.

Passenger Vehicle, Commercial Vehicle in the Global Car ABS Sensor Cable Market:

The Global Car ABS Sensor Cable Market plays a significant role in both passenger and commercial vehicles, ensuring safety and performance. In passenger vehicles, ABS sensor cables are crucial for maintaining control during emergency braking situations. These cables transmit data from the wheel speed sensors to the ABS control unit, allowing the system to modulate brake pressure and prevent wheel lock-up. This function is vital for passenger safety, as it helps maintain steering control and reduces stopping distances on slippery surfaces. The demand for ABS sensor cables in passenger vehicles is driven by increasing consumer awareness of vehicle safety features and regulatory mandates requiring ABS in new vehicles. In commercial vehicles, ABS sensor cables are equally important, given the larger size and weight of these vehicles. The ability to prevent wheel lock-up is crucial for maintaining stability and control, especially when carrying heavy loads. ABS sensor cables in commercial vehicles must be robust and reliable, capable of withstanding the harsh conditions and extended usage typical in commercial operations. The market for these cables is influenced by the growth of the logistics and transportation industries, which rely heavily on commercial vehicles. As these industries expand, the demand for reliable ABS sensor cables continues to rise. Manufacturers are focusing on developing cables that can meet the specific needs of both passenger and commercial vehicles, ensuring safety and performance across different vehicle types. The Global Car ABS Sensor Cable Market is thus integral to the automotive industry, contributing to the safety and efficiency of both passenger and commercial vehicles.

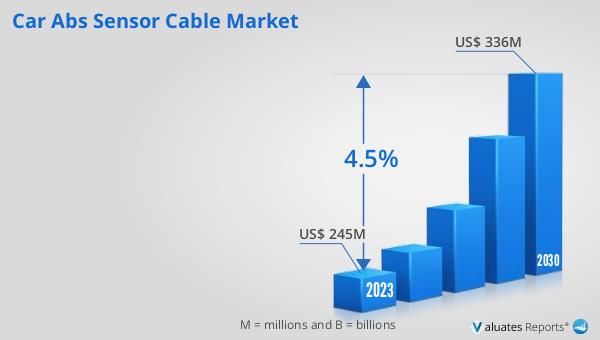

Global Car ABS Sensor Cable Market Outlook:

The outlook for the Global Car ABS Sensor Cable Market indicates a promising growth trajectory. The market is expected to expand from $258 million in 2024 to $336 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 4.5% during this period. This growth is driven by several factors, including the increasing adoption of ABS in vehicles, advancements in automotive technology, and the rising demand for vehicle safety features. As more countries implement regulations mandating the inclusion of ABS in vehicles, the demand for sensor cables is expected to rise. Additionally, the growing automotive industry, particularly in emerging markets, is contributing to the market's expansion. Manufacturers are investing in research and development to enhance the performance and cost-effectiveness of ABS sensor cables, further driving market growth. The competition between copper and aluminum core cables is also expected to intensify, leading to innovations in cable technology. Overall, the Global Car ABS Sensor Cable Market is poised for significant growth, driven by the increasing focus on vehicle safety and technological advancements in the automotive industry.

| Report Metric | Details |

| Report Name | Car ABS Sensor Cable Market |

| Accounted market size in 2024 | US$ 258 in million |

| Forecasted market size in 2030 | US$ 336 million |

| CAGR | 4.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Yazaki, LEONI, Prysmian Group, Coficab, TE Connectivity, Sumitomo Electric, Hitachi, Nexans, Furukawa Electric, Kyungshin, Beijing Force, LS Cable & System, Shanghai Shenglong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |