What is Global Automotive ABS Sensor Cable Market?

The Global Automotive ABS Sensor Cable Market is a crucial segment within the automotive industry, focusing on the production and distribution of cables used in Anti-lock Braking Systems (ABS). These sensor cables are integral to the functioning of ABS, which is a safety system that prevents the wheels of a vehicle from locking up during braking, thereby maintaining tractive contact with the road surface. This system enhances vehicle control and decreases stopping distances on dry and slippery surfaces. The market for these cables is driven by the increasing demand for safety features in vehicles, stringent government regulations regarding vehicle safety, and the growing automotive industry worldwide. As vehicles become more advanced, the need for reliable and efficient ABS sensor cables continues to rise. These cables must withstand harsh environmental conditions, including temperature fluctuations, moisture, and mechanical stress, making their quality and durability paramount. The market is characterized by continuous innovation and development to meet the evolving needs of the automotive sector, with manufacturers focusing on enhancing the performance and reliability of these cables. The global reach of this market is significant, with key players operating across various regions to cater to the diverse demands of automotive manufacturers.

Copper Core, Aluminum Core in the Global Automotive ABS Sensor Cable Market:

In the Global Automotive ABS Sensor Cable Market, the choice between copper core and aluminum core cables is a significant consideration for manufacturers and consumers alike. Copper core cables have long been favored in the industry due to their excellent electrical conductivity, flexibility, and durability. Copper's ability to conduct electricity efficiently makes it an ideal material for ABS sensor cables, ensuring that the signals from the sensors are transmitted accurately and promptly to the vehicle's braking system. This reliability is crucial for the proper functioning of ABS, which relies on precise and timely data to prevent wheel lockup during braking. Additionally, copper's flexibility allows for easier installation and routing within the vehicle, which can be a significant advantage in complex automotive designs. However, copper is relatively heavy and expensive, which can be a drawback in an industry that is increasingly focused on reducing vehicle weight and cost. On the other hand, aluminum core cables offer a lighter and more cost-effective alternative. Aluminum is less dense than copper, which means that cables made from this material can significantly reduce the overall weight of the vehicle. This reduction in weight can contribute to improved fuel efficiency and performance, which are critical considerations for modern automotive manufacturers. Furthermore, aluminum is generally less expensive than copper, making it an attractive option for cost-conscious manufacturers. However, aluminum's electrical conductivity is lower than that of copper, which can impact the performance of ABS sensor cables. To address this, manufacturers often use larger diameter aluminum cables or apply special coatings to enhance conductivity. Despite these efforts, aluminum cables may still not match the performance of their copper counterparts in certain applications. The choice between copper and aluminum core cables ultimately depends on the specific requirements of the vehicle and the priorities of the manufacturer. Some may prioritize the superior conductivity and reliability of copper, while others may opt for the weight and cost savings offered by aluminum. As the automotive industry continues to evolve, the demand for both types of cables is likely to persist, with manufacturers striving to balance performance, cost, and efficiency in their ABS sensor cable offerings.

Passenger Vehicle, Commercial Vehicle in the Global Automotive ABS Sensor Cable Market:

The usage of Global Automotive ABS Sensor Cable Market in passenger vehicles and commercial vehicles highlights the versatility and importance of these components in the automotive industry. In passenger vehicles, ABS sensor cables play a critical role in ensuring the safety and comfort of drivers and passengers. These cables are part of the ABS, which is a standard feature in most modern passenger cars. The ABS system helps prevent wheel lockup during emergency braking, allowing drivers to maintain control of the vehicle and avoid accidents. This safety feature is particularly important in passenger vehicles, where the protection of occupants is a top priority. The reliability and performance of ABS sensor cables are crucial in these vehicles, as they directly impact the effectiveness of the braking system. In commercial vehicles, the role of ABS sensor cables is equally important, albeit with some differences in focus. Commercial vehicles, such as trucks and buses, often operate under more demanding conditions than passenger vehicles. They carry heavier loads, travel longer distances, and may encounter more challenging driving environments. As a result, the ABS systems in these vehicles must be robust and reliable, capable of handling the increased stress and demands of commercial operations. ABS sensor cables in commercial vehicles must be designed to withstand these conditions, ensuring that the braking system functions effectively even under heavy loads and adverse conditions. The use of ABS sensor cables in both passenger and commercial vehicles underscores their critical role in vehicle safety and performance. As the automotive industry continues to prioritize safety and efficiency, the demand for high-quality ABS sensor cables is expected to grow. Manufacturers must continue to innovate and improve these components to meet the evolving needs of both passenger and commercial vehicle markets.

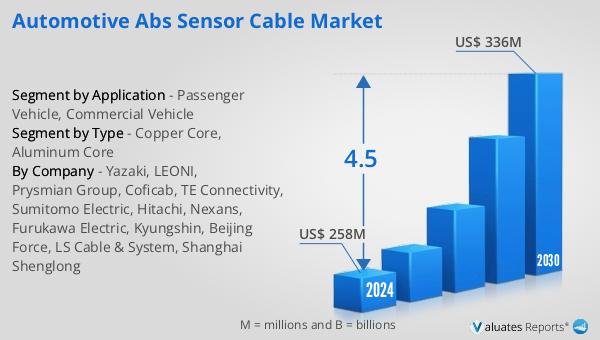

Global Automotive ABS Sensor Cable Market Outlook:

The global Automotive ABS Sensor Cable market is anticipated to experience significant growth over the coming years. Starting from a valuation of approximately US$ 258 million in 2024, the market is expected to reach around US$ 336 million by 2030. This growth trajectory represents a Compound Annual Growth Rate (CAGR) of 4.5% during the forecast period. This projected growth can be attributed to several factors, including the increasing demand for advanced safety features in vehicles, the expansion of the automotive industry, and the implementation of stringent safety regulations by governments worldwide. As consumers become more safety-conscious, the demand for vehicles equipped with reliable ABS systems is likely to rise, driving the need for high-quality ABS sensor cables. Additionally, the ongoing advancements in automotive technology and the trend towards electric and autonomous vehicles are expected to further fuel the demand for these components. The market's growth is also supported by the continuous efforts of manufacturers to innovate and improve the performance and reliability of ABS sensor cables, ensuring they meet the evolving needs of the automotive sector. As a result, the global Automotive ABS Sensor Cable market is poised for steady growth, offering opportunities for manufacturers and stakeholders in the industry.

| Report Metric | Details |

| Report Name | Automotive ABS Sensor Cable Market |

| Accounted market size in 2024 | US$ 258 in million |

| Forecasted market size in 2030 | US$ 336 million |

| CAGR | 4.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Yazaki, LEONI, Prysmian Group, Coficab, TE Connectivity, Sumitomo Electric, Hitachi, Nexans, Furukawa Electric, Kyungshin, Beijing Force, LS Cable & System, Shanghai Shenglong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |