What is Global Car Sensor Cable Market?

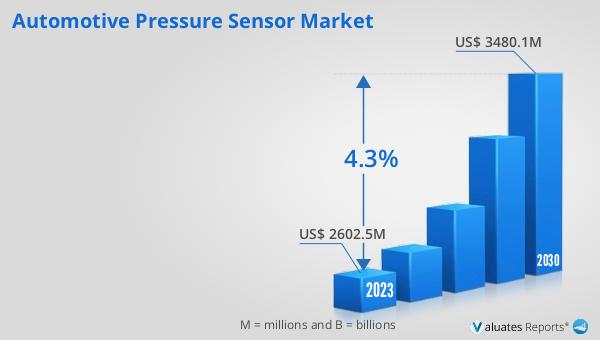

The Global Car Sensor Cable Market is a crucial component of the automotive industry, focusing on the production and distribution of cables used in various sensors within vehicles. These cables are essential for transmitting data from sensors to the vehicle's electronic control units (ECUs), enabling the efficient functioning of systems such as engine management, safety features, and infotainment. As vehicles become more advanced, the demand for reliable and high-performance sensor cables has increased. This market encompasses a wide range of cable types, including those made from different core materials like copper and aluminum, each offering unique benefits in terms of conductivity, weight, and cost. The growth of this market is driven by the increasing adoption of electric and autonomous vehicles, which require more sophisticated sensor systems. Additionally, stringent regulations on vehicle emissions and safety standards have further propelled the need for advanced sensor technologies, thereby boosting the demand for sensor cables. As the automotive industry continues to evolve, the Global Car Sensor Cable Market is expected to expand, offering new opportunities for innovation and development in cable technology.

Copper Core, Aluminum Core in the Global Car Sensor Cable Market:

In the Global Car Sensor Cable Market, copper core and aluminum core cables are two predominant types used in vehicle sensor systems. Copper core cables are highly valued for their excellent electrical conductivity, which ensures efficient data transmission between sensors and the vehicle's electronic systems. This high conductivity is crucial for maintaining the accuracy and reliability of sensor data, which is essential for the optimal performance of various vehicle functions, including engine management, safety systems, and infotainment. Copper cables are also known for their durability and resistance to corrosion, making them a preferred choice in environments where reliability is paramount. However, copper is relatively heavy and expensive, which can be a drawback in applications where weight and cost are critical considerations. On the other hand, aluminum core cables offer a lightweight and cost-effective alternative to copper. Aluminum is significantly lighter than copper, which can contribute to overall vehicle weight reduction, leading to improved fuel efficiency and performance. This is particularly important in the context of electric and hybrid vehicles, where weight savings can directly impact battery range and efficiency. Additionally, aluminum is more abundant and less expensive than copper, making it an attractive option for manufacturers looking to reduce material costs. However, aluminum's electrical conductivity is lower than that of copper, which can affect the performance of sensor systems if not properly accounted for in the cable design. To address this, manufacturers often use larger diameter aluminum cables or apply special coatings to enhance conductivity and performance. The choice between copper and aluminum core cables in the Global Car Sensor Cable Market often depends on the specific requirements of the vehicle and its sensor systems. For applications where high conductivity and reliability are paramount, such as in critical safety systems or high-performance vehicles, copper core cables may be preferred despite their higher cost and weight. Conversely, in applications where weight reduction and cost savings are prioritized, such as in electric vehicles or mass-market models, aluminum core cables may be more suitable. Ultimately, the decision is influenced by a range of factors, including the vehicle's design, the intended use of the sensor systems, and the manufacturer's cost and performance objectives. As the automotive industry continues to evolve, the demand for both copper and aluminum core cables is expected to grow, driven by the increasing complexity and sophistication of vehicle sensor systems. Advances in cable technology, such as improved insulation materials and innovative manufacturing processes, are likely to enhance the performance and reliability of both copper and aluminum core cables, further expanding their applications in the Global Car Sensor Cable Market. Additionally, ongoing research and development efforts aimed at improving the conductivity and durability of aluminum cables may help to address some of the current limitations, making them an even more viable alternative to copper in the future. As a result, both copper and aluminum core cables are expected to play a vital role in the continued growth and development of the Global Car Sensor Cable Market.

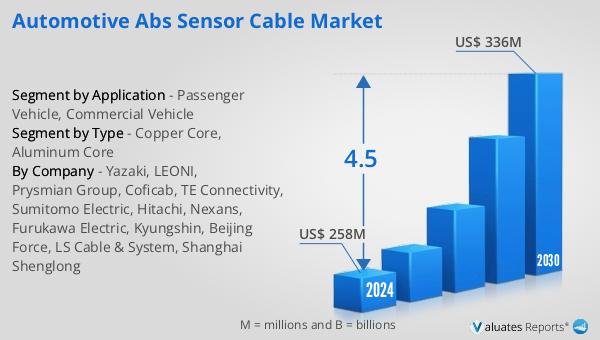

Passenger Vehicle, Commercial Vehicle in the Global Car Sensor Cable Market:

The Global Car Sensor Cable Market plays a significant role in the automotive industry, particularly in the context of passenger and commercial vehicles. In passenger vehicles, sensor cables are integral to a wide range of systems that enhance safety, performance, and comfort. These cables connect various sensors to the vehicle's electronic control units (ECUs), enabling the efficient functioning of systems such as anti-lock braking, airbag deployment, and adaptive cruise control. As passenger vehicles become more technologically advanced, the demand for high-quality sensor cables has increased, driven by the need for reliable data transmission and system integration. Additionally, the growing popularity of electric and hybrid vehicles has further fueled the demand for advanced sensor cables, as these vehicles require more sophisticated sensor systems to manage battery performance, energy efficiency, and driver assistance features. In commercial vehicles, the Global Car Sensor Cable Market is equally important, as these vehicles rely on robust sensor systems to ensure safety, efficiency, and compliance with regulatory standards. Sensor cables are used in a variety of applications, including engine management, emissions control, and telematics systems, which are essential for monitoring vehicle performance and optimizing fleet operations. The increasing adoption of telematics and fleet management solutions in commercial vehicles has driven the demand for reliable sensor cables, as these systems require accurate and timely data transmission to function effectively. Furthermore, the growing emphasis on reducing emissions and improving fuel efficiency in commercial vehicles has led to the development of advanced sensor technologies, which in turn has increased the demand for high-performance sensor cables. The usage of sensor cables in both passenger and commercial vehicles is expected to continue growing, driven by the increasing complexity and sophistication of vehicle systems. As the automotive industry moves towards greater connectivity and automation, the demand for reliable and high-performance sensor cables will become even more critical. Advances in cable technology, such as improved insulation materials and innovative manufacturing processes, are likely to enhance the performance and reliability of sensor cables, further expanding their applications in the Global Car Sensor Cable Market. Additionally, ongoing research and development efforts aimed at improving the conductivity and durability of sensor cables may help to address some of the current limitations, making them an even more viable solution for the automotive industry. Overall, the Global Car Sensor Cable Market is poised for continued growth, driven by the increasing demand for advanced sensor systems in both passenger and commercial vehicles. As vehicle technology continues to evolve, the need for reliable and high-performance sensor cables will remain a key focus for manufacturers and suppliers, offering new opportunities for innovation and development in cable technology. The ongoing advancements in sensor cable technology are expected to play a crucial role in shaping the future of the automotive industry, enabling the development of safer, more efficient, and more connected vehicles.

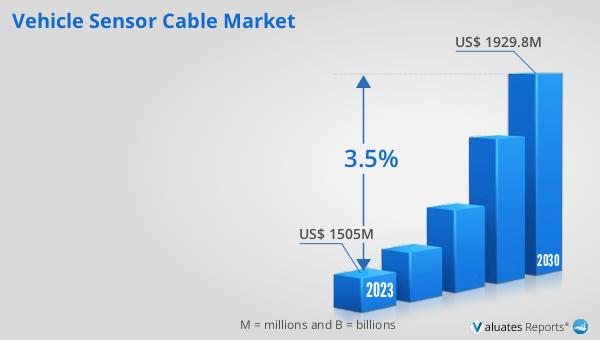

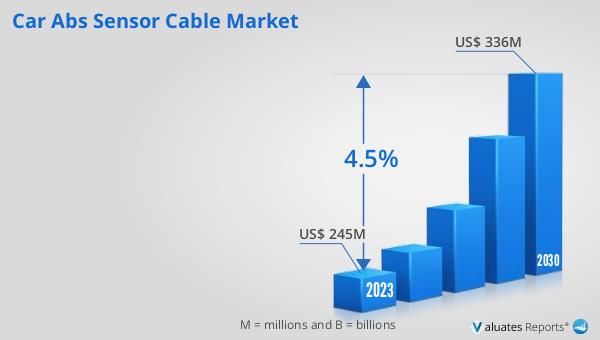

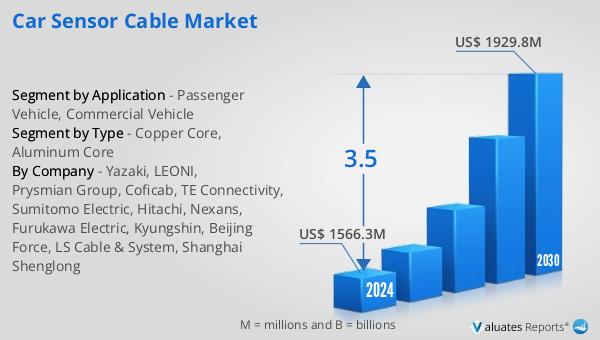

Global Car Sensor Cable Market Outlook:

The outlook for the Global Car Sensor Cable Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of approximately $1,566.3 million in 2024 to around $1,929.8 million by 2030. This growth represents a Compound Annual Growth Rate (CAGR) of 3.5% throughout the forecast period. This steady increase in market size reflects the rising demand for sensor cables driven by advancements in vehicle technology and the growing adoption of electric and autonomous vehicles. As vehicles become more sophisticated, the need for reliable and high-performance sensor cables becomes increasingly critical, supporting the efficient functioning of various systems such as safety features, engine management, and infotainment. The projected growth of the Global Car Sensor Cable Market is also influenced by stringent regulations on vehicle emissions and safety standards, which necessitate the use of advanced sensor technologies. These regulations drive the demand for high-quality sensor cables that can ensure accurate data transmission and system integration. Additionally, the increasing focus on connectivity and automation in the automotive industry further fuels the demand for sensor cables, as these systems rely on precise and timely data transmission to operate effectively. As the market continues to grow, manufacturers and suppliers are likely to invest in research and development to enhance the performance and reliability of sensor cables. This includes exploring new materials, improving insulation technologies, and developing innovative manufacturing processes to meet the evolving needs of the automotive industry. The ongoing advancements in sensor cable technology are expected to play a crucial role in shaping the future of the Global Car Sensor Cable Market, enabling the development of safer, more efficient, and more connected vehicles.

| Report Metric | Details |

| Report Name | Car Sensor Cable Market |

| Accounted market size in 2024 | US$ 1566.3 million |

| Forecasted market size in 2030 | US$ 1929.8 million |

| CAGR | 3.5 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Yazaki, LEONI, Prysmian Group, Coficab, TE Connectivity, Sumitomo Electric, Hitachi, Nexans, Furukawa Electric, Kyungshin, Beijing Force, LS Cable & System, Shanghai Shenglong |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |