What is Organic Iodine Contrast Agent - Global Market?

Organic iodine contrast agents are specialized substances used in medical imaging to enhance the visibility of internal structures in the body. These agents are particularly valuable in procedures like X-rays and CT scans, where they help to highlight blood vessels, organs, and tissues, making it easier for healthcare professionals to diagnose various conditions. The global market for organic iodine contrast agents is driven by the increasing demand for advanced diagnostic imaging techniques, which are essential for accurate disease detection and management. As healthcare systems worldwide continue to adopt more sophisticated imaging technologies, the need for effective contrast agents grows. This market is characterized by ongoing research and development efforts aimed at improving the safety and efficacy of these agents, as well as expanding their applications. Additionally, the aging global population and rising prevalence of chronic diseases contribute to the demand for diagnostic imaging, further propelling the market for organic iodine contrast agents. As a result, this market is poised for steady growth, with manufacturers focusing on innovation and strategic partnerships to meet the evolving needs of healthcare providers and patients.

Ionic Type, Nonionic Type in the Organic Iodine Contrast Agent - Global Market:

Organic iodine contrast agents can be broadly categorized into two types: ionic and nonionic. Ionic contrast agents are composed of iodine atoms bound to a carrier molecule that dissociates into charged particles, or ions, when introduced into the body. These agents have been used for many years and are known for their effectiveness in enhancing imaging quality. However, they are also associated with a higher risk of adverse reactions, such as allergic responses and nephrotoxicity, due to their high osmolality, which refers to the concentration of particles in a solution. Despite these risks, ionic contrast agents remain in use, particularly in situations where cost is a significant consideration, as they are generally less expensive than their nonionic counterparts. On the other hand, nonionic contrast agents are designed to minimize the risk of adverse reactions. They do not dissociate into ions, resulting in lower osmolality and, consequently, a reduced likelihood of side effects. This makes nonionic agents the preferred choice in many clinical settings, especially for patients with a history of allergies or kidney problems. The development of nonionic contrast agents represents a significant advancement in medical imaging, as they offer a safer alternative without compromising diagnostic efficacy. The choice between ionic and nonionic contrast agents often depends on various factors, including patient health, the specific imaging procedure, and cost considerations. In recent years, there has been a noticeable shift towards the use of nonionic agents, driven by the growing emphasis on patient safety and the increasing availability of these agents. Manufacturers are continually working to improve the formulation of nonionic contrast agents, focusing on enhancing their imaging capabilities while further reducing the risk of adverse effects. This ongoing innovation is crucial for meeting the demands of modern healthcare, where precision and safety are paramount. As the global market for organic iodine contrast agents evolves, the distinction between ionic and nonionic types remains a key consideration for healthcare providers and patients alike. Understanding the differences between these two types of agents is essential for making informed decisions about their use in medical imaging.

Hospitals, Clinics, Diagnostic and Imaging Centers, Others in the Organic Iodine Contrast Agent - Global Market:

Organic iodine contrast agents play a crucial role in various healthcare settings, including hospitals, clinics, diagnostic and imaging centers, and other medical facilities. In hospitals, these agents are integral to a wide range of diagnostic procedures, from routine check-ups to complex surgeries. They are used in imaging techniques such as CT scans, angiography, and fluoroscopy, helping doctors to visualize internal structures with greater clarity. This enhanced imaging capability is vital for accurate diagnosis and treatment planning, particularly in emergency situations where time is of the essence. In clinics, organic iodine contrast agents are often used in outpatient imaging procedures. These settings require efficient and effective diagnostic tools to manage a high volume of patients. The use of contrast agents in clinics allows for quick and accurate assessments, enabling healthcare providers to make informed decisions about patient care. Diagnostic and imaging centers, which specialize in advanced imaging technologies, rely heavily on organic iodine contrast agents to deliver high-quality images. These centers often serve as referral points for complex cases, where detailed imaging is necessary to guide treatment decisions. The use of contrast agents in these facilities ensures that patients receive the most accurate and comprehensive diagnostic evaluations possible. Beyond hospitals, clinics, and imaging centers, organic iodine contrast agents are also used in other healthcare settings, such as research institutions and specialized medical practices. In these environments, contrast agents are employed in a variety of research and clinical applications, from studying disease mechanisms to developing new diagnostic techniques. The versatility of organic iodine contrast agents makes them indispensable across the healthcare spectrum, supporting a wide range of diagnostic and therapeutic activities. As the demand for advanced imaging continues to grow, the use of these agents is expected to expand, further solidifying their role in modern medicine.

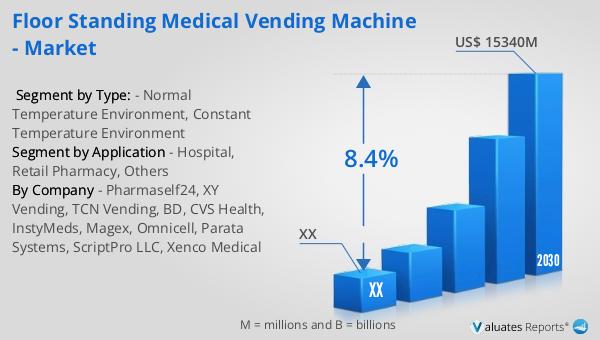

Organic Iodine Contrast Agent - Global Market Outlook:

The global market for organic iodine contrast agents was valued at approximately $4,719 million in 2023. It is projected to grow to a revised size of around $5,981.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced diagnostic imaging techniques and the essential role that contrast agents play in enhancing imaging quality. In North America, the market for organic iodine contrast agents was valued at a significant amount in 2023, with expectations of continued growth through 2030. The CAGR for this region during the forecast period is anticipated to align with global trends, underscoring the importance of these agents in the region's healthcare landscape. The steady growth of the market is driven by factors such as the rising prevalence of chronic diseases, advancements in imaging technology, and the increasing emphasis on patient safety. As healthcare providers continue to adopt more sophisticated imaging solutions, the demand for effective and safe contrast agents is expected to rise, further fueling market expansion.

| Report Metric | Details |

| Report Name | Organic Iodine Contrast Agent - Market |

| Forecasted market size in 2030 | US$ 5981.8 million |

| CAGR | 3.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | GE Healthcare, Koninklijke Philips, Siemens Healthineers, Canon, Shimadzu, Boston Scientific, Cordis, Medtronic, AngioDynamics, B. Braun Melsungen, Abbott Laboratories |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |