What is High Voltage Wind Cable - Global Market?

High Voltage Wind Cables are essential components in the global energy infrastructure, particularly in the realm of renewable energy. These cables are designed to transmit electricity generated by wind turbines, which are often located in remote or offshore areas, to the main power grid. The demand for high voltage wind cables is driven by the increasing adoption of wind energy as a sustainable and clean power source. As countries strive to reduce their carbon footprint and transition to renewable energy, the need for efficient and reliable transmission systems becomes paramount. High voltage wind cables are engineered to withstand harsh environmental conditions, such as strong winds, saltwater, and temperature fluctuations, ensuring the consistent delivery of electricity. The global market for these cables is expanding as more wind farms are being developed worldwide, necessitating advanced cable technologies to support the growing energy demands. This market growth is further fueled by technological advancements that enhance the durability and efficiency of these cables, making them a crucial element in the global shift towards renewable energy.

XLPE Cable, PVC Cable in the High Voltage Wind Cable - Global Market:

XLPE (Cross-Linked Polyethylene) and PVC (Polyvinyl Chloride) cables are two prominent types of cables used in the high voltage wind cable market. XLPE cables are known for their superior thermal and mechanical properties, making them ideal for high voltage applications. They are designed to handle high electrical loads and are resistant to heat, moisture, and chemicals, which makes them suitable for use in harsh environments like offshore wind farms. The cross-linking process in XLPE cables enhances their thermal stability and mechanical strength, allowing them to operate efficiently under high stress and temperature conditions. This makes XLPE cables a preferred choice for transmitting electricity over long distances, as they minimize energy loss and ensure reliable power delivery. On the other hand, PVC cables are valued for their flexibility and cost-effectiveness. They are commonly used in less demanding applications where extreme environmental conditions are not a concern. PVC cables are easy to install and maintain, making them a practical choice for onshore wind farms and other installations where cost is a significant factor. However, they may not offer the same level of performance as XLPE cables in high voltage and harsh environmental conditions. The choice between XLPE and PVC cables in the high voltage wind cable market often depends on the specific requirements of the project, including the environmental conditions, distance of power transmission, and budget constraints. As the global market for high voltage wind cables continues to grow, the demand for both XLPE and PVC cables is expected to rise, driven by the increasing number of wind energy projects worldwide. The development of new materials and technologies is also likely to enhance the performance and efficiency of these cables, further boosting their adoption in the renewable energy sector.

Intertidal Wind Power, Nearshore Wind Power in the High Voltage Wind Cable - Global Market:

High voltage wind cables play a crucial role in the development of intertidal and nearshore wind power projects. Intertidal wind power refers to wind farms located in the intertidal zone, the area that is above water at low tide and underwater at high tide. These locations offer unique challenges and opportunities for wind power generation. High voltage wind cables used in intertidal wind power projects must be designed to withstand the dynamic environmental conditions, including tidal movements, saltwater exposure, and varying temperatures. These cables are essential for transmitting the electricity generated by the wind turbines to the onshore power grid, ensuring a stable and reliable energy supply. Nearshore wind power, on the other hand, involves wind farms located close to the shore, typically within a few kilometers of the coastline. These projects benefit from easier access for installation and maintenance compared to offshore wind farms, but they still require robust high voltage wind cables to handle the electrical load and environmental conditions. The use of high voltage wind cables in nearshore wind power projects is critical for efficient power transmission and minimizing energy loss over the distance. Both intertidal and nearshore wind power projects contribute significantly to the global renewable energy landscape, providing clean and sustainable energy solutions. The demand for high voltage wind cables in these areas is expected to grow as more countries invest in wind energy to meet their renewable energy targets. The development of advanced cable technologies will further enhance the efficiency and reliability of power transmission in intertidal and nearshore wind power projects, supporting the global transition to a more sustainable energy future.

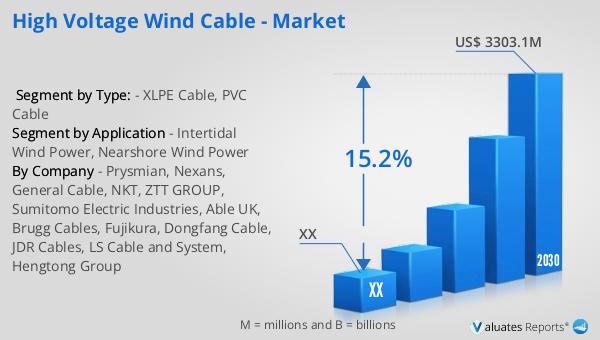

High Voltage Wind Cable - Global Market Outlook:

In 2023, the global market for High Voltage Wind Cables was valued at approximately $1,324.7 million. This market is projected to experience significant growth, with expectations to reach a revised size of around $3,303.1 million by the year 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 15.2% during the forecast period from 2024 to 2030. This impressive growth rate underscores the increasing demand for high voltage wind cables as the world continues to shift towards renewable energy sources. The expansion of wind energy projects, both onshore and offshore, is a key driver of this market growth. As countries strive to reduce their reliance on fossil fuels and lower carbon emissions, the need for efficient and reliable power transmission systems becomes more critical. High voltage wind cables are essential for connecting wind farms to the main power grid, ensuring a stable and consistent energy supply. The market's growth is also supported by technological advancements that enhance the performance and durability of these cables, making them more efficient and cost-effective. As the global energy landscape continues to evolve, the demand for high voltage wind cables is expected to rise, driven by the increasing adoption of wind energy as a clean and sustainable power source.

| Report Metric | Details |

| Report Name | High Voltage Wind Cable - Market |

| Forecasted market size in 2030 | US$ 3303.1 million |

| CAGR | 15.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Prysmian, Nexans, General Cable, NKT, ZTT GROUP, Sumitomo Electric Industries, Able UK, Brugg Cables, Fujikura, Dongfang Cable, JDR Cables, LS Cable and System, Hengtong Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |