What is Global Conductive Linoleum Flooring Market?

The Global Conductive Linoleum Flooring Market refers to the worldwide industry focused on the production and distribution of linoleum flooring that has conductive properties. This type of flooring is designed to prevent the buildup of static electricity, which can be crucial in environments where static discharge could damage sensitive equipment or create safety hazards. Conductive linoleum flooring is made by incorporating conductive materials into the linoleum, allowing it to dissipate static electricity safely. This market includes various stakeholders such as manufacturers, suppliers, and end-users across different sectors like medical, electrical, industrial, data centers, and laboratories. The demand for conductive linoleum flooring is driven by the need for safer and more reliable flooring solutions in these critical environments. As technology advances and industries become more reliant on sensitive electronic equipment, the importance of conductive flooring solutions continues to grow.

Static Dissipative Type, Static Conductive Type in the Global Conductive Linoleum Flooring Market:

In the Global Conductive Linoleum Flooring Market, there are two main types of flooring: Static Dissipative and Static Conductive. Static Dissipative flooring is designed to control the discharge of static electricity by allowing it to flow through the flooring material at a controlled rate. This type of flooring is typically used in environments where static discharge could interfere with sensitive electronic equipment but does not pose a significant safety risk. Static Dissipative flooring is often found in office spaces, retail environments, and other areas where electronic devices are used but not in large quantities. On the other hand, Static Conductive flooring is designed to provide a direct path for static electricity to flow to the ground, effectively preventing any buildup of static charge. This type of flooring is essential in environments where even a small static discharge could cause significant damage or pose a safety risk, such as in manufacturing facilities, laboratories, and data centers. Static Conductive flooring is made with materials that have a higher conductivity than Static Dissipative flooring, ensuring that static electricity is quickly and safely dissipated. Both types of flooring are crucial in maintaining the safety and functionality of environments that rely on sensitive electronic equipment. The choice between Static Dissipative and Static Conductive flooring depends on the specific needs of the environment and the level of static control required.

Medical, Electrical, Industrial, Data Centers and Labs, Others in the Global Conductive Linoleum Flooring Market:

The usage of Global Conductive Linoleum Flooring Market spans across various critical areas such as medical, electrical, industrial, data centers, and laboratories. In the medical field, conductive linoleum flooring is essential in operating rooms, intensive care units, and other areas where sensitive medical equipment is used. The flooring helps to prevent static discharge that could interfere with the operation of life-saving devices and ensures a safe environment for both patients and healthcare providers. In the electrical sector, conductive linoleum flooring is used in manufacturing facilities, assembly lines, and other areas where electronic components are produced or handled. The flooring helps to protect sensitive electronic components from static discharge, reducing the risk of damage and ensuring the reliability of the final products. In industrial settings, conductive linoleum flooring is used in environments where flammable materials are present, such as chemical plants and refineries. The flooring helps to prevent static discharge that could ignite flammable substances, ensuring a safe working environment for employees. In data centers, conductive linoleum flooring is crucial in preventing static discharge that could damage servers and other critical infrastructure. The flooring helps to maintain the reliability and uptime of data centers, which are essential for the operation of modern businesses. In laboratories, conductive linoleum flooring is used to protect sensitive equipment and experiments from static discharge. The flooring helps to ensure the accuracy and reliability of scientific research and experiments. Overall, the usage of conductive linoleum flooring in these critical areas helps to protect sensitive equipment, ensure safety, and maintain the reliability of operations.

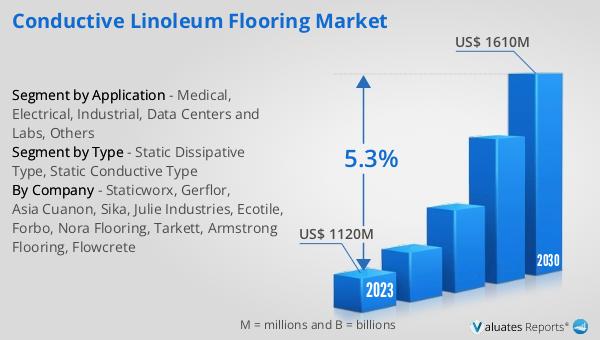

Global Conductive Linoleum Flooring Market Outlook:

The global Conductive Linoleum Flooring market was valued at US$ 1120 million in 2023 and is anticipated to reach US$ 1610 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for conductive flooring solutions across various sectors. The growth is attributed to the rising awareness of the importance of static control in environments where sensitive electronic equipment is used. As industries continue to adopt advanced technologies and rely more on electronic devices, the need for reliable and effective conductive flooring solutions is expected to grow. The market's growth is also supported by advancements in flooring materials and manufacturing processes, which have made conductive linoleum flooring more accessible and cost-effective. The steady growth rate of 5.3% CAGR reflects the ongoing demand for conductive flooring solutions and the industry's ability to meet this demand through innovation and improved product offerings.

| Report Metric | Details |

| Report Name | Conductive Linoleum Flooring Market |

| Accounted market size in 2023 | US$ 1120 million |

| Forecasted market size in 2030 | US$ 1610 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Staticworx, Gerflor, Asia Cuanon, Sika, Julie Industries, Ecotile, Forbo, Nora Flooring, Tarkett, Armstrong Flooring, Flowcrete |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |