What is Global Hot Dog Roller Machine Market?

The Global Hot Dog Roller Machine Market refers to the worldwide industry focused on the production, distribution, and sale of machines designed to cook hot dogs evenly and efficiently. These machines are commonly used in various food service settings, including cinemas, dining rooms, entertainment venues, convenience stores, and other locations where quick and consistent food preparation is essential. The market encompasses a range of products, from small countertop units suitable for limited space environments to larger, more industrial models designed for high-volume usage. The demand for hot dog roller machines is driven by the growing popularity of hot dogs as a convenient and tasty snack, as well as the need for reliable and easy-to-use cooking equipment in commercial settings. Technological advancements have also played a role in the market's growth, with newer models offering features such as adjustable temperature controls, non-stick rollers, and energy-efficient designs. Overall, the Global Hot Dog Roller Machine Market is a dynamic and evolving sector that caters to the needs of various food service providers around the world.

Flat Grill, Tilted Grill in the Global Hot Dog Roller Machine Market:

Flat grills and tilted grills are two types of cooking surfaces commonly used in the Global Hot Dog Roller Machine Market. Flat grills, as the name suggests, have a flat cooking surface that allows for even heat distribution and consistent cooking results. These grills are ideal for cooking a variety of foods, including hot dogs, burgers, and sandwiches. The flat surface ensures that the food is cooked evenly, reducing the risk of burning or undercooking. Additionally, flat grills are easy to clean and maintain, making them a popular choice for busy food service establishments. On the other hand, tilted grills have a sloped cooking surface that allows excess grease and fat to drain away from the food. This feature is particularly beneficial for cooking hot dogs, as it helps to reduce the fat content and create a healthier product. Tilted grills also provide a unique cooking experience, as the sloped surface allows for better heat circulation and faster cooking times. Both flat and tilted grills have their advantages and are used in different settings depending on the specific needs of the food service provider. In the Global Hot Dog Roller Machine Market, the choice between flat and tilted grills often comes down to personal preference and the type of food being prepared. Some establishments may prefer the even cooking and easy maintenance of flat grills, while others may opt for the healthier cooking and faster results offered by tilted grills. Ultimately, both types of grills play a crucial role in the market, providing food service providers with the tools they need to deliver high-quality hot dogs and other grilled foods to their customers.

Cinema, Dining Room, Entertainment Place, Convenience Store, Other in the Global Hot Dog Roller Machine Market:

The usage of Global Hot Dog Roller Machines spans various areas, including cinemas, dining rooms, entertainment places, convenience stores, and other locations. In cinemas, hot dog roller machines are a staple at concession stands, providing moviegoers with a quick and tasty snack option. The machines' ability to cook multiple hot dogs simultaneously ensures that there is always a fresh supply ready for customers, even during peak times. In dining rooms, particularly in casual dining establishments and buffets, hot dog roller machines offer a convenient way to serve hot dogs as part of a larger menu. The machines' consistent cooking results and ease of use make them a valuable addition to any dining room setup. Entertainment places, such as amusement parks, sports arenas, and concert venues, also benefit from the use of hot dog roller machines. These locations often experience high foot traffic and require efficient food service solutions to keep customers satisfied. Hot dog roller machines provide a reliable and quick way to serve hot dogs, ensuring that guests can enjoy their favorite snacks without long wait times. Convenience stores are another key area where hot dog roller machines are commonly used. These stores often have limited space and need compact, efficient cooking equipment to offer a variety of food options to customers. Hot dog roller machines fit this requirement perfectly, allowing convenience stores to serve hot dogs alongside other quick snacks and beverages. Finally, other locations, such as gas stations, food trucks, and school cafeterias, also utilize hot dog roller machines to meet the demand for quick and easy food options. The versatility and efficiency of these machines make them a valuable asset in any setting where fast food service is needed. Overall, the Global Hot Dog Roller Machine Market plays a crucial role in various areas, providing food service providers with the tools they need to deliver high-quality hot dogs to their customers.

Global Hot Dog Roller Machine Market Outlook:

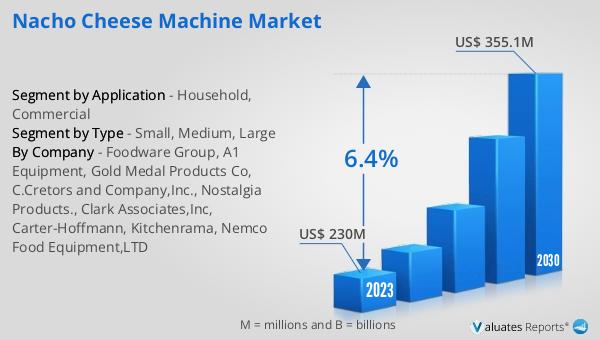

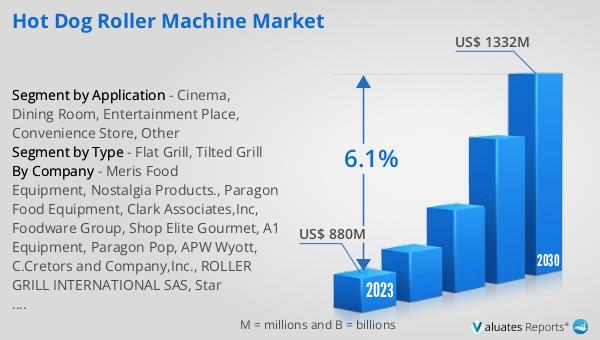

The global Hot Dog Roller Machine market was valued at US$ 880 million in 2023 and is anticipated to reach US$ 1332 million by 2030, witnessing a CAGR of 6.1% during the forecast period 2024-2030. According to Vetnosis, the value of the global animal health industry will increase by 12% to $38.3 billion in 2021. According to the data of the 2022 China Pet Medical Industry White Paper, from the perspective of market size, the scale of China's pet medical market is about 67.5 billion, accounting for about 22.5% of the entire pet industry.

| Report Metric | Details |

| Report Name | Hot Dog Roller Machine Market |

| Accounted market size in 2023 | US$ 880 million |

| Forecasted market size in 2030 | US$ 1332 million |

| CAGR | 6.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Meris Food Equipment, Nostalgia Products., Paragon Food Equipment, Clark Associates,Inc, Foodware Group, Shop Elite Gourmet, A1 Equipment, Paragon Pop, APW Wyott, C.Cretors and Company,Inc., ROLLER GRILL INTERNATIONAL SAS, Star Manufacturing, Gold Medal Products Co, Antunes, Olde Midway, Vollrath Foodservice, Nemco Food Equipment,LTD |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |