What is Global Laser Fabricated Medical Assemblies Market?

The Global Laser Fabricated Medical Assemblies Market refers to the industry that focuses on the production and distribution of medical devices and components created using laser fabrication technology. Laser fabrication involves the use of laser beams to cut, shape, and assemble materials with high precision. This technology is particularly valuable in the medical field due to its ability to produce intricate and delicate components that meet stringent quality standards. The market encompasses a wide range of products, including surgical instruments, implants, diagnostic devices, and other medical tools. The demand for laser-fabricated medical assemblies is driven by the need for advanced medical technologies that offer improved performance, reliability, and patient outcomes. As healthcare systems worldwide continue to evolve and adopt new technologies, the Global Laser Fabricated Medical Assemblies Market is expected to grow, providing innovative solutions to meet the increasing demands of the medical industry.

Metallic Material, Non-metallic Material in the Global Laser Fabricated Medical Assemblies Market:

In the Global Laser Fabricated Medical Assemblies Market, materials play a crucial role in determining the performance and reliability of the final products. Metallic materials, such as stainless steel, titanium, and cobalt-chromium alloys, are commonly used in laser fabrication due to their strength, durability, and biocompatibility. These materials are ideal for creating surgical instruments, implants, and other medical devices that require high precision and resistance to wear and corrosion. Stainless steel, for example, is widely used in the production of surgical tools and orthopedic implants due to its excellent mechanical properties and resistance to rust. Titanium, on the other hand, is favored for its lightweight nature and high strength-to-weight ratio, making it suitable for implants and prosthetics that need to be both strong and lightweight. Cobalt-chromium alloys are also used in medical applications where high wear resistance and biocompatibility are essential, such as in dental implants and joint replacements. Non-metallic materials, including polymers, ceramics, and composites, are also extensively used in the Global Laser Fabricated Medical Assemblies Market. Polymers, such as polyethylene, polycarbonate, and polyetheretherketone (PEEK), offer versatility and ease of fabrication, making them suitable for a wide range of medical devices. Polyethylene is commonly used in the production of disposable medical instruments and packaging due to its low cost and flexibility. Polycarbonate is known for its impact resistance and optical clarity, making it ideal for applications such as surgical instrument handles and diagnostic device housings. PEEK, a high-performance polymer, is used in implants and other medical devices that require high strength, chemical resistance, and biocompatibility. Ceramics, such as alumina and zirconia, are valued for their hardness, wear resistance, and biocompatibility. These materials are often used in dental implants, joint replacements, and other applications where long-term durability and stability are critical. Alumina is known for its excellent wear resistance and is commonly used in hip and knee replacements. Zirconia, with its high fracture toughness and aesthetic appeal, is widely used in dental crowns and bridges. Composites, which combine the properties of different materials, offer unique advantages in the Global Laser Fabricated Medical Assemblies Market. For example, carbon fiber-reinforced polymers provide high strength and stiffness while remaining lightweight, making them suitable for applications such as prosthetics and orthopedic devices. These composites can be tailored to meet specific performance requirements, offering a balance of strength, flexibility, and biocompatibility. The choice of material in laser-fabricated medical assemblies depends on various factors, including the intended application, mechanical and chemical properties, biocompatibility, and cost. The ability to precisely control the laser fabrication process allows manufacturers to create complex geometries and intricate designs that meet the stringent requirements of the medical industry. As technology continues to advance, the development of new materials and fabrication techniques will further enhance the capabilities and applications of laser-fabricated medical assemblies, driving innovation and growth in the market.

Medical, Electronic, Aerospace, Other in the Global Laser Fabricated Medical Assemblies Market:

The Global Laser Fabricated Medical Assemblies Market finds applications across various industries, including medical, electronic, aerospace, and others. In the medical field, laser-fabricated assemblies are used to create a wide range of devices and components that are essential for diagnosis, treatment, and patient care. Surgical instruments, such as scalpels, forceps, and scissors, benefit from the precision and sharpness achieved through laser fabrication. Implants, including orthopedic screws, plates, and dental implants, are manufactured using laser technology to ensure high accuracy and biocompatibility. Diagnostic devices, such as endoscopes and imaging equipment, also rely on laser-fabricated components for their intricate designs and reliable performance. The ability to produce complex geometries and fine features makes laser fabrication an ideal choice for medical applications where precision and quality are paramount. In the electronics industry, laser-fabricated assemblies are used to create components for various electronic devices and systems. Printed circuit boards (PCBs), which are the backbone of electronic devices, are often manufactured using laser technology to achieve high precision and fine detail. Laser fabrication allows for the creation of intricate patterns and connections on PCBs, ensuring reliable performance and miniaturization of electronic devices. Additionally, laser-fabricated components are used in the production of sensors, connectors, and other electronic parts that require high precision and durability. The ability to work with a wide range of materials, including metals and polymers, makes laser fabrication a versatile and valuable technology in the electronics industry. The aerospace industry also benefits from the Global Laser Fabricated Medical Assemblies Market, particularly in the production of components that require high precision, strength, and reliability. Laser fabrication is used to create parts for aircraft engines, structural components, and other critical systems. The ability to produce complex shapes and fine details with high accuracy makes laser fabrication an ideal choice for aerospace applications where performance and safety are critical. Materials such as titanium and high-performance polymers are commonly used in aerospace components due to their strength, lightweight nature, and resistance to extreme conditions. Laser-fabricated assemblies in the aerospace industry contribute to the overall performance, efficiency, and safety of aircraft and spacecraft. Beyond the medical, electronic, and aerospace industries, laser-fabricated assemblies find applications in various other fields. In the automotive industry, laser fabrication is used to create components for engines, transmissions, and other critical systems. The precision and reliability of laser-fabricated parts contribute to the overall performance and efficiency of vehicles. In the telecommunications industry, laser-fabricated components are used in the production of fiber optic connectors, switches, and other devices that require high precision and reliability. The ability to work with a wide range of materials and create intricate designs makes laser fabrication a valuable technology in various industries. Overall, the Global Laser Fabricated Medical Assemblies Market plays a crucial role in advancing technology and innovation across multiple industries. The precision, reliability, and versatility of laser fabrication make it an ideal choice for creating complex and high-performance components that meet the stringent requirements of various applications. As technology continues to evolve, the demand for laser-fabricated assemblies is expected to grow, driving further advancements and applications in the medical, electronic, aerospace, and other industries.

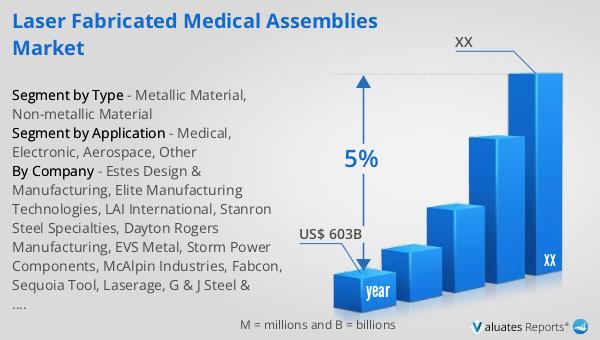

Global Laser Fabricated Medical Assemblies Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately USD 603 billion by the year 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is driven by the increasing demand for advanced medical technologies and devices that offer improved patient outcomes and enhanced performance. The market encompasses a wide range of products, including diagnostic devices, surgical instruments, implants, and other medical tools that are essential for modern healthcare systems. As healthcare providers continue to adopt new technologies and invest in innovative solutions, the global market for medical devices is expected to expand, providing opportunities for manufacturers and suppliers to meet the evolving needs of the medical industry. The projected growth rate reflects the ongoing advancements in medical technology, the rising prevalence of chronic diseases, and the increasing focus on improving healthcare infrastructure and services worldwide. With the continuous development of new materials, fabrication techniques, and medical applications, the global market for medical devices is poised for significant growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Laser Fabricated Medical Assemblies Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Estes Design & Manufacturing, Elite Manufacturing Technologies, LAI International, Stanron Steel Specialties, Dayton Rogers Manufacturing, EVS Metal, Storm Power Components, McAlpin Industries, Fabcon, Sequoia Tool, Laserage, G & J Steel & Tubing, PMF Industries, Marshall Manufacturing Company, Rockford Specialties, J&E Manufacturing, Schmid Tool & Engineering, RPM Engineering Corp., Vita Needle, Wisconsin Metal Parts, MicroGroup, Quasar Industries, Accurate Metal Fabricating |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |