What is Global Heliox (Helium/Oxygen Mixtures) Market?

The Global Heliox (Helium/Oxygen Mixtures) Market refers to the industry that produces and distributes mixtures of helium and oxygen gases. These mixtures, commonly known as Heliox, are used in various applications due to their unique properties. Heliox is lighter than air and has a lower density, which makes it easier to breathe, especially in medical and diving scenarios. The market encompasses the production, distribution, and sale of different Heliox mixtures, such as 79/21 (79% helium and 21% oxygen) and 70/30 (70% helium and 30% oxygen), among others. The demand for Heliox is driven by its effectiveness in treating respiratory conditions, its use in deep-sea diving to prevent nitrogen narcosis, and its application in other specialized fields. The market is influenced by factors such as technological advancements, regulatory policies, and the growing awareness of Heliox's benefits. Companies operating in this market focus on research and development to improve the efficiency and safety of Heliox mixtures, aiming to meet the diverse needs of their customers.

79/21(Helium/Oxygen), 70/30(Helium/Oxygen), Others in the Global Heliox (Helium/Oxygen Mixtures) Market:

The Global Heliox (Helium/Oxygen Mixtures) Market includes various mixtures, primarily 79/21 and 70/30, along with other combinations. The 79/21 mixture, consisting of 79% helium and 21% oxygen, is widely used in medical settings. This specific ratio is effective in reducing airway resistance and improving ventilation in patients with respiratory issues such as asthma, chronic obstructive pulmonary disease (COPD), and other obstructive airway conditions. The lower density of Heliox compared to air allows it to flow more easily through constricted airways, making it easier for patients to breathe. The 70/30 mixture, which contains 70% helium and 30% oxygen, is often used in both medical and diving applications. In medical scenarios, it serves a similar purpose as the 79/21 mixture but provides a higher concentration of oxygen, which can be beneficial in certain clinical situations where patients require more oxygen. In diving, the 70/30 mixture is used to prevent nitrogen narcosis and decompression sickness, allowing divers to reach greater depths safely. Other Heliox mixtures may be tailored for specific applications, depending on the required balance of helium and oxygen. These mixtures are used in various industries, including aerospace, where they help in testing and calibrating equipment, and in scientific research, where precise gas mixtures are needed for experiments. The production of these mixtures involves careful control of the gas ratios to ensure safety and effectiveness. Companies in the Heliox market invest in advanced technologies and equipment to produce high-quality mixtures that meet stringent regulatory standards. The market also sees continuous innovation, with new mixtures being developed to cater to emerging needs in different sectors. Overall, the diversity of Heliox mixtures available in the market highlights the versatility and importance of these gases in various applications.

Medical Uses, Diving Uses in the Global Heliox (Helium/Oxygen Mixtures) Market:

The usage of Global Heliox (Helium/Oxygen Mixtures) Market in medical and diving applications is significant due to the unique properties of Heliox. In medical uses, Heliox is primarily employed to treat patients with respiratory conditions. Its lower density compared to air allows it to flow more easily through narrowed airways, reducing the work of breathing for patients with conditions such as asthma, COPD, and bronchiolitis. Heliox therapy can be administered through various devices, including nebulizers, ventilators, and face masks, providing relief and improving oxygenation in patients experiencing respiratory distress. Additionally, Heliox is used in critical care settings to manage severe cases of airway obstruction and to facilitate mechanical ventilation in patients with compromised lung function. Its ability to improve gas exchange and reduce airway resistance makes it a valuable tool in respiratory therapy. In diving uses, Heliox is essential for deep-sea diving operations. The mixture of helium and oxygen helps prevent nitrogen narcosis, a condition caused by the increased partial pressure of nitrogen at greater depths, which can impair cognitive and motor functions. By replacing nitrogen with helium, divers can safely reach deeper depths without experiencing the narcotic effects of nitrogen. Heliox also reduces the risk of decompression sickness, commonly known as "the bends," by minimizing the formation of nitrogen bubbles in the bloodstream during ascent. This makes Heliox an indispensable gas mixture for commercial, scientific, and military diving operations. The use of Heliox in diving requires careful planning and monitoring to ensure the correct gas mixture is used at different depths, and divers must undergo specialized training to handle the complexities of breathing Heliox underwater. Overall, the medical and diving applications of Heliox highlight its critical role in enhancing safety and effectiveness in these fields.

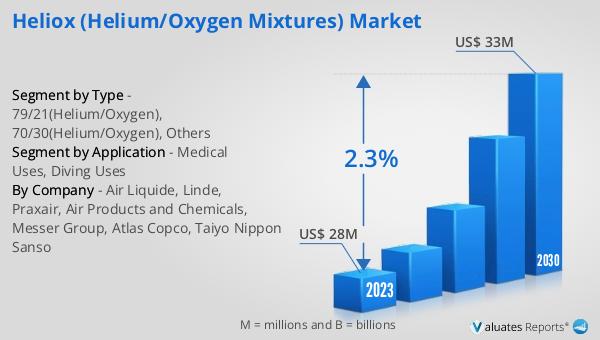

Global Heliox (Helium/Oxygen Mixtures) Market Outlook:

The global Heliox (Helium/Oxygen Mixtures) market is anticipated to grow from an estimated value of US$ 29 million in 2024 to reach approximately US$ 33 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. This growth projection underscores the increasing demand for Heliox in various applications, driven by its unique properties and benefits. The market's expansion is influenced by factors such as advancements in medical technology, the growing prevalence of respiratory conditions, and the rising need for safe and effective gas mixtures in deep-sea diving. Companies operating in this market are likely to focus on innovation and the development of new Heliox mixtures to cater to the evolving needs of their customers. Additionally, regulatory policies and standards play a crucial role in shaping the market dynamics, ensuring the safety and quality of Heliox products. As awareness of the benefits of Heliox continues to grow, the market is expected to witness steady growth, providing opportunities for companies to expand their product offerings and reach new customer segments.

| Report Metric | Details |

| Report Name | Heliox (Helium/Oxygen Mixtures) Market |

| Accounted market size in 2024 | an estimated US$ 29 million |

| Forecasted market size in 2030 | US$ 33 million |

| CAGR | 2.3% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Air Liquide, Linde, Praxair, Air Products and Chemicals, Messer Group, Atlas Copco, Taiyo Nippon Sanso |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |