What is Global Thermoplastic Styrene Block Copolymer (TPS) Market?

Global Thermoplastic Styrene Block Copolymer (TPS) Market refers to the worldwide industry focused on the production, distribution, and application of thermoplastic styrene block copolymers. These materials are a type of thermoplastic elastomer, which means they combine the elastic properties of rubber with the processability of plastics. TPS materials are known for their versatility, durability, and ease of processing, making them suitable for a wide range of applications. They are used in various industries, including automotive, construction, healthcare, and consumer goods, due to their excellent impact resistance, flexibility, and ability to withstand varying temperatures. The market for TPS is driven by the increasing demand for lightweight and high-performance materials, as well as the growing emphasis on sustainability and recyclability in material selection. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the TPS market is expected to expand, offering new opportunities for manufacturers and end-users alike. The global reach of this market highlights its importance in modern manufacturing and its potential to influence future material trends.

Styrene-Butadiene-Styrene (SBS), Styrene-Isoprene-Styrene (SIS), SEBS, SEPS, Others in the Global Thermoplastic Styrene Block Copolymer (TPS) Market:

Styrene-Butadiene-Styrene (SBS), Styrene-Isoprene-Styrene (SIS), SEBS, SEPS, and other variants are key components of the Global Thermoplastic Styrene Block Copolymer (TPS) Market, each offering unique properties and applications. SBS is one of the most widely used types of TPS due to its excellent elasticity and strength. It is often used in applications requiring high impact resistance and flexibility, such as footwear, adhesives, and sealants. SBS is also popular in asphalt modification, where it enhances the durability and performance of road surfaces. Styrene-Isoprene-Styrene (SIS) is another important variant, known for its superior tackiness and adhesive properties. SIS is commonly used in pressure-sensitive adhesives, making it ideal for labels, tapes, and other adhesive products. Its ability to provide strong adhesion without the need for additional curing processes makes it a preferred choice in many industrial applications. SEBS, or Styrene-Ethylene-Butylene-Styrene, is a hydrogenated version of SBS, offering improved thermal stability and weather resistance. This makes SEBS suitable for outdoor applications and products that require long-term durability, such as automotive parts and roofing materials. SEBS is also used in medical devices and consumer goods, where its non-toxic and hypoallergenic properties are valued. SEPS, or Styrene-Ethylene-Propylene-Styrene, is similar to SEBS but offers even greater flexibility and resilience. It is often used in applications that require a soft touch and high elasticity, such as personal care products and flexible tubing. The versatility of SEPS makes it a valuable material in industries ranging from healthcare to electronics. Other TPS variants include specialized copolymers designed for specific applications, such as those with enhanced chemical resistance or flame retardancy. These specialized materials expand the potential uses of TPS and allow manufacturers to tailor their products to meet specific performance requirements. Overall, the diversity of TPS materials, including SBS, SIS, SEBS, SEPS, and others, highlights the adaptability and innovation within the market. As industries continue to evolve and demand more advanced materials, the role of these copolymers in providing solutions that balance performance, cost, and sustainability will only grow.

Asphalt Modification, Footwear, Polymer Modification, Adhesives and Sealants, Other in the Global Thermoplastic Styrene Block Copolymer (TPS) Market:

The Global Thermoplastic Styrene Block Copolymer (TPS) Market finds extensive usage across various sectors, each benefiting from the unique properties of these materials. In asphalt modification, TPS, particularly SBS, is used to enhance the performance of road surfaces. By improving the elasticity and durability of asphalt, SBS-modified roads can better withstand temperature fluctuations and heavy traffic, leading to longer-lasting and more resilient infrastructure. This application is crucial in regions with extreme weather conditions, where road maintenance and longevity are significant concerns. In the footwear industry, TPS materials are prized for their flexibility, comfort, and durability. They are used in the production of soles and other components, providing the necessary cushioning and support for various types of footwear. The lightweight nature of TPS also contributes to the overall comfort and wearability of shoes, making them a popular choice among manufacturers aiming to deliver high-quality products. Polymer modification is another area where TPS materials play a vital role. By blending TPS with other polymers, manufacturers can enhance the properties of the base material, such as impact resistance, flexibility, and processability. This modification process allows for the creation of customized materials tailored to specific applications, ranging from automotive parts to consumer electronics. In the adhesives and sealants industry, TPS materials, especially SIS, are valued for their strong adhesive properties and ease of application. They are used in a variety of products, including tapes, labels, and construction sealants, where reliable adhesion and flexibility are essential. The ability of TPS-based adhesives to bond with different substrates without the need for additional curing processes makes them a convenient and efficient choice for many applications. Beyond these primary areas, TPS materials are also used in other sectors, such as healthcare, where their non-toxic and hypoallergenic properties are beneficial. They are employed in the production of medical devices, personal care products, and packaging materials, where safety and performance are paramount. The versatility and adaptability of TPS materials make them a valuable resource across multiple industries, driving innovation and offering solutions that meet the evolving demands of modern manufacturing.

Global Thermoplastic Styrene Block Copolymer (TPS) Market Outlook:

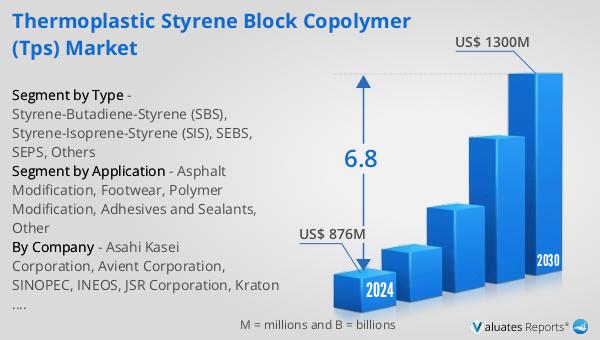

The global Thermoplastic Styrene Block Copolymer (TPS) market is anticipated to experience significant growth in the coming years. Starting from a valuation of approximately US$ 876 million in 2024, the market is expected to reach around US$ 1300 million by 2030. This growth trajectory represents a Compound Annual Growth Rate (CAGR) of 6.8% over the forecast period. This upward trend is indicative of the increasing demand for TPS materials across various industries, driven by their unique properties and versatility. As industries continue to seek materials that offer a balance of performance, cost-effectiveness, and sustainability, TPS materials are well-positioned to meet these needs. The projected growth of the TPS market underscores the importance of these materials in modern manufacturing and their potential to influence future material trends. With advancements in technology and a growing emphasis on sustainable practices, the TPS market is poised to expand, offering new opportunities for manufacturers and end-users alike. This growth not only highlights the value of TPS materials but also reflects the broader trends in the global market towards innovative and sustainable solutions.

| Report Metric | Details |

| Report Name | Thermoplastic Styrene Block Copolymer (TPS) Market |

| Accounted market size in 2024 | US$ 876 million |

| Forecasted market size in 2030 | US$ 1300 million |

| CAGR | 6.8 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Asahi Kasei Corporation, Avient Corporation, SINOPEC, INEOS, JSR Corporation, Kraton Corporation, Kuraray, LCY Group, LG Chem, TSRC, Zeon Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |