What is Global Automatic Die Bonder Equipment Market?

The Global Automatic Die Bonder Equipment Market refers to the industry focused on the production and distribution of machines that are essential in the semiconductor manufacturing process. These machines, known as die bonders, are used to attach semiconductor chips onto substrates, which is a critical step in the assembly of electronic devices. The market for these machines is driven by the increasing demand for electronic devices, advancements in technology, and the need for more efficient and precise manufacturing processes. As the electronics industry continues to grow, particularly with the rise of smartphones, tablets, and other smart devices, the demand for automatic die bonders is expected to increase. These machines offer high precision and speed, which are crucial for meeting the production demands of modern electronics. The market is characterized by a range of products that vary in terms of automation level, speed, and precision, catering to different needs within the semiconductor industry.

Fully Automatic, Semi-Automatic in the Global Automatic Die Bonder Equipment Market:

In the Global Automatic Die Bonder Equipment Market, machines are categorized based on their level of automation, primarily into fully automatic and semi-automatic systems. Fully automatic die bonders are designed to perform the die bonding process with minimal human intervention. These machines are equipped with advanced features such as automated wafer handling, precise alignment systems, and sophisticated software controls that ensure high accuracy and repeatability. They are ideal for high-volume production environments where speed and precision are paramount. Fully automatic systems can significantly reduce labor costs and increase throughput, making them a preferred choice for large-scale semiconductor manufacturers. On the other hand, semi-automatic die bonders require some level of human involvement in the operation. While they still offer a degree of automation, such as automated die pick-up and placement, operators are needed to perform tasks like loading wafers and substrates. Semi-automatic systems are often used in smaller production runs or in environments where flexibility and customization are more important than sheer volume. These machines provide a balance between automation and manual control, allowing manufacturers to adapt to varying production needs. Both types of die bonders play a crucial role in the semiconductor manufacturing process, each offering unique advantages depending on the specific requirements of the production line. The choice between fully automatic and semi-automatic systems depends on factors such as production volume, budget, and the complexity of the devices being manufactured. As technology continues to evolve, the capabilities of both fully automatic and semi-automatic die bonders are expected to improve, offering even greater efficiency and precision to semiconductor manufacturers.

Integrated Device Manufacturers (IDMs), Outsourced Semiconductor Assembly and Test (OSAT) in the Global Automatic Die Bonder Equipment Market:

The Global Automatic Die Bonder Equipment Market finds significant usage in two main areas: Integrated Device Manufacturers (IDMs) and Outsourced Semiconductor Assembly and Test (OSAT) companies. IDMs are companies that design, manufacture, and sell integrated circuit products. They rely heavily on automatic die bonders to streamline their production processes and ensure the high quality of their semiconductor devices. For IDMs, the precision and speed offered by automatic die bonders are crucial for maintaining competitive advantage in the fast-paced electronics market. These machines enable IDMs to produce large volumes of chips with consistent quality, meeting the demands of various electronic applications. On the other hand, OSAT companies specialize in providing assembly and testing services for semiconductor manufacturers. They play a critical role in the semiconductor supply chain by offering cost-effective solutions for packaging and testing chips. Automatic die bonders are essential for OSAT companies as they allow for efficient and accurate assembly of semiconductor devices. By utilizing these machines, OSAT companies can offer high-quality services to their clients, ensuring that the chips are properly bonded and ready for testing. The use of automatic die bonders in both IDMs and OSAT companies highlights the importance of these machines in the semiconductor industry. They not only enhance production efficiency but also contribute to the overall quality and reliability of electronic devices. As the demand for semiconductors continues to rise, the role of automatic die bonders in IDMs and OSAT companies is expected to become even more critical, driving further advancements in the technology and capabilities of these machines.

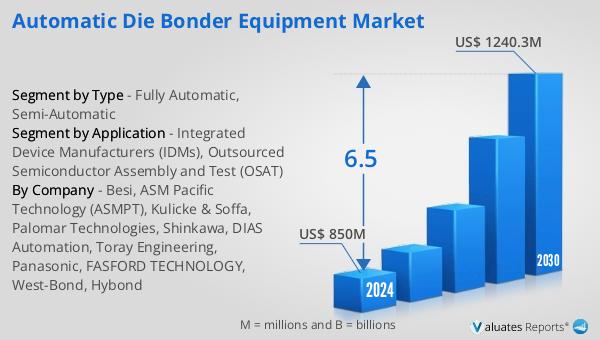

Global Automatic Die Bonder Equipment Market Outlook:

The outlook for the Global Automatic Die Bonder Equipment Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of US$ 850 million in 2024 to approximately US$ 1240.3 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 6.5% over the forecast period. This growth is driven by the increasing demand for semiconductor devices across various industries, including consumer electronics, automotive, and telecommunications. Europe plays a significant role in this market, accounting for over 32% of the total output volume of global die bonder equipment. This highlights the region's strong presence and influence in the semiconductor manufacturing sector. Among the key players in the market, Besi stands out as the leading manufacturer, holding a substantial market share of 39% in terms of revenue. This dominance underscores Besi's expertise and innovation in producing high-quality die bonder equipment that meets the evolving needs of the semiconductor industry. As the market continues to grow, companies like Besi are expected to play a pivotal role in shaping the future of die bonding technology, driving further advancements and efficiencies in semiconductor manufacturing processes.

| Report Metric | Details |

| Report Name | Automatic Die Bonder Equipment Market |

| Accounted market size in 2024 | US$ 850 in million |

| Forecasted market size in 2030 | US$ 1240.3 million |

| CAGR | 6.5 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Besi, ASM Pacific Technology (ASMPT), Kulicke & Soffa, Palomar Technologies, Shinkawa, DIAS Automation, Toray Engineering, Panasonic, FASFORD TECHNOLOGY, West-Bond, Hybond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |