What is Global Conductive FIBC Market?

The Global Conductive FIBC Market refers to the worldwide industry focused on the production and distribution of conductive Flexible Intermediate Bulk Containers (FIBCs). These containers are specially designed to safely transport and store dry, flowable products such as powders, granules, and other bulk materials. Conductive FIBCs are made from woven polypropylene fabrics that are interwoven with conductive threads, which help to dissipate static electricity. This feature is crucial in preventing sparks that could ignite flammable materials, making them ideal for industries dealing with combustible substances. The market for these containers is driven by the increasing demand for safe and efficient packaging solutions across various sectors, including chemicals, pharmaceuticals, food and beverages, and agriculture. As industries continue to prioritize safety and efficiency, the demand for conductive FIBCs is expected to grow, offering opportunities for manufacturers to innovate and expand their product offerings. The market is characterized by a diverse range of products, catering to different industrial needs, and is supported by advancements in material technology and manufacturing processes. Overall, the Global Conductive FIBC Market plays a vital role in enhancing safety and operational efficiency in bulk material handling.

Woven, Non-woven in the Global Conductive FIBC Market:

In the Global Conductive FIBC Market, woven and non-woven materials play a significant role in the construction and functionality of these containers. Woven conductive FIBCs are made from interlaced polypropylene fibers, which provide strength and durability. The weaving process involves creating a fabric by interlacing two sets of yarns at right angles, resulting in a strong and flexible material. This woven structure is then integrated with conductive threads, which are typically made from carbon or other conductive materials, to ensure the dissipation of static electricity. The woven design allows for high tensile strength, making these FIBCs suitable for heavy-duty applications where robustness is essential. They are commonly used in industries that require the safe handling of large volumes of materials, such as chemicals and construction. On the other hand, non-woven conductive FIBCs are made from bonded fibers, which are not woven together but rather held together by chemical, mechanical, or thermal means. This process results in a fabric that is generally lighter and more flexible than woven materials. Non-woven FIBCs are often used in applications where weight and flexibility are more critical than tensile strength. The conductive properties in non-woven FIBCs are achieved through the incorporation of conductive materials during the bonding process, ensuring that static electricity is effectively managed. These containers are particularly useful in industries where the ease of handling and adaptability to different shapes and sizes are important, such as in the food and beverage sector. Both woven and non-woven conductive FIBCs offer unique advantages and are chosen based on the specific requirements of the application. Woven FIBCs are preferred for their strength and durability, making them ideal for transporting heavy and abrasive materials. They are also more resistant to tearing and puncturing, which is crucial in maintaining the integrity of the contents during transportation and storage. Non-woven FIBCs, while not as strong as their woven counterparts, offer greater flexibility and are often more cost-effective. They are easier to manufacture in various shapes and sizes, providing versatility for different packaging needs. The choice between woven and non-woven conductive FIBCs often depends on factors such as the nature of the material being transported, the required level of static protection, and the environmental conditions in which the containers will be used. For instance, in environments where moisture resistance is crucial, woven FIBCs with additional coatings or liners may be preferred. In contrast, non-woven FIBCs might be chosen for applications where quick and easy handling is a priority. In conclusion, the Global Conductive FIBC Market offers a range of options in both woven and non-woven materials, each catering to specific industrial needs. The decision to use one over the other is influenced by the balance between strength, flexibility, cost, and the level of static protection required. As industries continue to evolve and demand more specialized packaging solutions, the market for both woven and non-woven conductive FIBCs is expected to grow, driven by innovations in material technology and manufacturing processes.

Food and Beverages, Agricultural Products, Chemicals, Building and Construction, Others in the Global Conductive FIBC Market:

The Global Conductive FIBC Market finds extensive usage across various industries, including food and beverages, agricultural products, chemicals, building and construction, and others. In the food and beverage industry, conductive FIBCs are used to transport and store bulk quantities of ingredients such as sugar, flour, and grains. The conductive properties of these containers ensure that static electricity does not accumulate, which is crucial in preventing contamination and maintaining the quality of the food products. Additionally, the flexibility and strength of conductive FIBCs make them ideal for handling large volumes of food materials efficiently and safely. In the agricultural sector, conductive FIBCs are used to transport and store seeds, fertilizers, and other agricultural products. The ability to dissipate static electricity is particularly important in this industry, as it helps prevent the ignition of flammable materials and ensures the safety of workers handling these products. Conductive FIBCs also offer protection against moisture and pests, which is essential for preserving the quality of agricultural products during storage and transportation. The chemical industry is another major user of conductive FIBCs, as these containers are designed to safely handle hazardous and flammable materials. The conductive properties of these FIBCs prevent the buildup of static electricity, reducing the risk of explosions and fires. This makes them an essential component in the safe transportation and storage of chemicals, ensuring compliance with safety regulations and protecting both workers and the environment. In the building and construction industry, conductive FIBCs are used to transport and store materials such as cement, sand, and gravel. The strength and durability of these containers make them suitable for handling heavy and abrasive materials, while their conductive properties help prevent static-related hazards. Conductive FIBCs also offer the advantage of being reusable, which is an important consideration in the construction industry, where cost-effectiveness and sustainability are key concerns. Other industries that utilize conductive FIBCs include pharmaceuticals, mining, and electronics. In the pharmaceutical industry, these containers are used to transport and store bulk quantities of raw materials and finished products, ensuring that they remain free from contamination and static-related issues. In the mining industry, conductive FIBCs are used to handle bulk quantities of minerals and ores, providing a safe and efficient means of transportation. In the electronics industry, these containers are used to transport and store sensitive components, protecting them from static electricity and ensuring their integrity. Overall, the Global Conductive FIBC Market plays a crucial role in enhancing safety and efficiency across a wide range of industries. The ability to safely transport and store bulk materials while preventing static-related hazards makes conductive FIBCs an indispensable tool for businesses looking to optimize their operations and ensure the safety of their products and personnel. As industries continue to evolve and demand more specialized packaging solutions, the market for conductive FIBCs is expected to grow, driven by innovations in material technology and manufacturing processes.

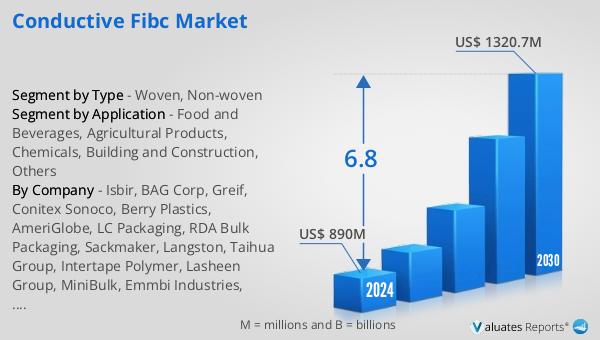

Global Conductive FIBC Market Outlook:

The outlook for the Global Conductive FIBC Market indicates a promising growth trajectory over the coming years. Starting from a valuation of approximately US$ 890 million in 2024, the market is anticipated to expand significantly, reaching an estimated value of US$ 1320.7 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period. This upward trend can be attributed to several factors, including the increasing demand for safe and efficient packaging solutions across various industries such as chemicals, pharmaceuticals, food and beverages, and agriculture. As these industries continue to prioritize safety and operational efficiency, the need for conductive FIBCs is likely to rise, driving market growth. The projected growth of the Global Conductive FIBC Market also reflects the ongoing advancements in material technology and manufacturing processes. Manufacturers are continually innovating to develop more effective and cost-efficient conductive FIBCs, catering to the diverse needs of different industries. This includes the development of new materials and designs that enhance the strength, flexibility, and static-dissipative properties of these containers. Additionally, the increasing focus on sustainability and environmental responsibility is expected to drive demand for reusable and recyclable conductive FIBCs, further contributing to market expansion. In conclusion, the Global Conductive FIBC Market is poised for significant growth in the coming years, driven by the increasing demand for safe and efficient packaging solutions across various industries. As manufacturers continue to innovate and develop new products, the market is expected to expand, offering opportunities for businesses to enhance their operations and ensure the safety of their products and personnel.

| Report Metric | Details |

| Report Name | Conductive FIBC Market |

| Accounted market size in 2024 | US$ 890 million |

| Forecasted market size in 2030 | US$ 1320.7 million |

| CAGR | 6.8 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Segment by Region |

|

| By Company | Isbir, BAG Corp, Greif, Conitex Sonoco, Berry Plastics, AmeriGlobe, LC Packaging, RDA Bulk Packaging, Sackmaker, Langston, Taihua Group, Intertape Polymer, Lasheen Group, MiniBulk, Emmbi Industries, Dongxing Plastic, Yantai Haiwan, Kanpur Plastipack |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |