What is Global Aluminum-Zinc Alloy Coated Sheet Steel Market?

The Global Aluminum-Zinc Alloy Coated Sheet Steel Market refers to the industry involved in the production and distribution of sheet steel coated with an aluminum-zinc alloy. This type of coated steel is known for its superior corrosion resistance, heat reflectivity, and durability, making it a popular choice in various industries. The coating typically consists of 55% aluminum, 43.4% zinc, and 1.6% silicon, which provides a robust protective layer against environmental elements. The market for this material is driven by its widespread application in construction, automotive, and appliance manufacturing, among others. As industries continue to seek materials that offer longevity and cost-effectiveness, the demand for aluminum-zinc alloy coated sheet steel is expected to grow. This market is characterized by technological advancements in coating processes, increasing demand for lightweight and high-strength materials, and the need for sustainable and environmentally friendly products. The global reach of this market is significant, with major production and consumption occurring in regions such as Asia-Pacific, North America, and Europe. The market dynamics are influenced by factors such as raw material availability, technological innovations, and regulatory standards related to environmental protection and sustainability.

Below 0.4mm, 0.4mm-2.0mm, Above 2.0mm in the Global Aluminum-Zinc Alloy Coated Sheet Steel Market:

In the Global Aluminum-Zinc Alloy Coated Sheet Steel Market, the thickness of the sheets plays a crucial role in determining their application and performance. Sheets with a thickness below 0.4mm are typically used in applications where flexibility and lightweight properties are essential. These thin sheets are often employed in the manufacturing of small appliances, electronic casings, and intricate architectural designs where precision and detail are paramount. The thinness allows for easy manipulation and shaping, making them ideal for complex designs and structures. On the other hand, sheets with a thickness ranging from 0.4mm to 2.0mm are more versatile and are commonly used in a broader range of applications. This thickness range strikes a balance between strength and flexibility, making these sheets suitable for use in the automotive industry, construction, and larger appliances. They provide adequate structural support while still being manageable in terms of weight and ease of installation. The automotive industry, in particular, benefits from this thickness range as it allows for the production of lightweight yet durable vehicle components, contributing to fuel efficiency and overall vehicle performance. Sheets with a thickness above 2.0mm are typically used in heavy-duty applications where strength and durability are of utmost importance. These thicker sheets are often employed in the construction of large structures, such as bridges, industrial buildings, and heavy machinery. The increased thickness provides enhanced load-bearing capacity and resistance to environmental stressors, making them ideal for use in harsh environments and demanding applications. In the construction industry, these thick sheets are used for roofing, cladding, and structural components that require high strength and longevity. The choice of sheet thickness is influenced by factors such as the specific requirements of the application, cost considerations, and the desired balance between weight and strength. Manufacturers and consumers must carefully consider these factors when selecting the appropriate thickness for their needs. Additionally, advancements in coating technology and material science continue to expand the possibilities for the use of aluminum-zinc alloy coated sheet steel across various thicknesses, further driving innovation and growth in the market. As industries continue to evolve and demand more efficient and sustainable materials, the importance of selecting the right sheet thickness becomes increasingly critical. The ability to tailor the properties of aluminum-zinc alloy coated sheet steel to meet specific application requirements ensures its continued relevance and demand in the global market.

Architecture Industry, Automobile Industry, Appliance Industry, Others in the Global Aluminum-Zinc Alloy Coated Sheet Steel Market:

The Global Aluminum-Zinc Alloy Coated Sheet Steel Market finds extensive usage across various industries, each benefiting from the unique properties of this material. In the architecture industry, aluminum-zinc alloy coated sheet steel is widely used for roofing, cladding, and structural components. Its excellent corrosion resistance and aesthetic appeal make it a preferred choice for modern architectural designs. The material's ability to withstand harsh weather conditions and its reflective properties contribute to energy efficiency in buildings, making it an environmentally friendly option. Architects and builders appreciate its versatility, as it can be easily shaped and customized to fit specific design requirements. In the automobile industry, aluminum-zinc alloy coated sheet steel is used in the manufacturing of vehicle bodies, chassis, and other components. The material's lightweight nature contributes to improved fuel efficiency and reduced emissions, aligning with the industry's push towards sustainability. Its high strength-to-weight ratio ensures safety and durability, making it suitable for critical automotive applications. The material's resistance to corrosion also extends the lifespan of vehicles, reducing maintenance costs and enhancing overall performance. In the appliance industry, aluminum-zinc alloy coated sheet steel is used in the production of household appliances such as refrigerators, washing machines, and ovens. The material's durability and resistance to rust make it ideal for appliances that are exposed to moisture and varying temperatures. Its smooth surface finish and ability to hold paint well allow for aesthetically pleasing designs that complement modern home interiors. Manufacturers benefit from the material's cost-effectiveness and ease of fabrication, enabling efficient production processes. Beyond these industries, aluminum-zinc alloy coated sheet steel is also used in other sectors such as agriculture, where it is employed in the construction of silos, barns, and other structures. Its ability to withstand environmental stressors and its long lifespan make it a reliable choice for agricultural applications. The material's versatility and adaptability to different environments and requirements underscore its importance in the global market. As industries continue to prioritize sustainability, efficiency, and cost-effectiveness, the demand for aluminum-zinc alloy coated sheet steel is expected to grow, driven by its proven performance and wide-ranging applications.

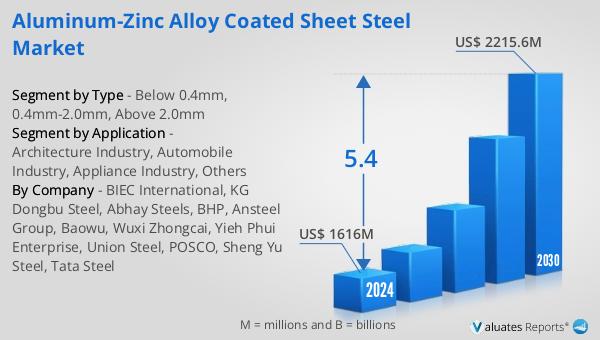

Global Aluminum-Zinc Alloy Coated Sheet Steel Market Outlook:

The global market for Aluminum-Zinc Alloy Coated Sheet Steel is anticipated to expand from $1,616 million in 2024 to $2,215.6 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 5.4% over the forecast period. In the first eleven months of 2022, China's crude steel production reached 935 million tons, marking a 1.4% decrease compared to the previous year, while total steel production was 1.226 billion tons, down 0.7% year-on-year. Based on data from the Steel Association's ten-day report, it is projected that China's crude steel output for the entire year of 2022 will range between 1.01 billion and 1.02 billion tons, representing an approximate 2% decline from the previous year. According to the World Steel Association, global crude steel production in the first eleven months of 2022 was 1.691 billion tons, a decrease of 3.7% year-on-year. During this period, China's share of global crude steel production was 55.29%, an increase of 1.31 percentage points compared to the previous year. These figures highlight the significant role China plays in the global steel industry, despite the overall decline in production. The market dynamics are influenced by various factors, including technological advancements, environmental regulations, and the growing demand for sustainable materials. As industries continue to evolve and adapt to changing market conditions, the Aluminum-Zinc Alloy Coated Sheet Steel Market is poised for growth, driven by its versatility and wide-ranging applications.

| Report Metric | Details |

| Report Name | Aluminum-Zinc Alloy Coated Sheet Steel Market |

| Accounted market size in 2024 | US$ 1616 million |

| Forecasted market size in 2030 | US$ 2215.6 million |

| CAGR | 5.4 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | BIEC International, KG Dongbu Steel, Abhay Steels, BHP, Ansteel Group, Baowu, Wuxi Zhongcai, Yieh Phui Enterprise, Union Steel, POSCO, Sheng Yu Steel, Tata Steel |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |