What is Global Wax Inhibitor Market?

The Global Wax Inhibitor Market is a specialized segment within the broader chemical industry, focusing on products designed to prevent the formation of wax deposits in crude oil. Wax inhibitors are crucial in maintaining the flow of crude oil through pipelines, especially in colder climates where wax formation can be a significant issue. These inhibitors work by altering the wax crystal structure, preventing them from aggregating and forming blockages. The market for wax inhibitors is driven by the increasing demand for efficient crude oil transportation and processing solutions. As the global energy demand continues to rise, the need for effective flow assurance technologies like wax inhibitors becomes more critical. The market is characterized by a diverse range of products, each tailored to specific types of crude oil and environmental conditions. Companies operating in this market invest heavily in research and development to create more effective and environmentally friendly solutions. The Global Wax Inhibitor Market is expected to grow steadily as oil exploration and production activities expand, particularly in regions with challenging environmental conditions. This growth is supported by technological advancements and the increasing complexity of oil extraction processes, which require more sophisticated flow assurance solutions.

Polymer Type, Surfactant Type, Compound Type in the Global Wax Inhibitor Market:

In the Global Wax Inhibitor Market, products are categorized based on their chemical composition and functionality, with three primary types being Polymer Type, Surfactant Type, and Compound Type. Polymer Type wax inhibitors are widely used due to their effectiveness in modifying the wax crystal structure, thereby preventing the aggregation of wax particles. These inhibitors are typically composed of long-chain polymers that interact with the wax molecules, altering their growth pattern and reducing their ability to form large crystals. This type of inhibitor is particularly effective in environments where the crude oil has a high wax content, as it can significantly reduce the viscosity of the oil, facilitating smoother transportation through pipelines. Surfactant Type wax inhibitors, on the other hand, function by reducing the surface tension between the wax particles and the crude oil, preventing the wax from adhering to the pipeline walls. These inhibitors are often used in conjunction with other types of inhibitors to enhance their overall effectiveness. Surfactants are particularly useful in situations where the crude oil has a lower wax content, as they can prevent the initial formation of wax deposits. Compound Type wax inhibitors are a combination of various chemical agents, including polymers and surfactants, designed to provide a comprehensive solution to wax formation. These inhibitors are tailored to specific crude oil compositions and environmental conditions, offering a versatile solution for a wide range of applications. The development of compound type inhibitors involves extensive research and testing to ensure their effectiveness across different scenarios. Each type of wax inhibitor has its advantages and limitations, and the choice of inhibitor depends on factors such as the composition of the crude oil, the environmental conditions, and the specific requirements of the transportation or processing system. Companies in the Global Wax Inhibitor Market continuously innovate to develop more effective and environmentally friendly solutions, driven by the increasing demand for efficient crude oil transportation and processing technologies. The market is highly competitive, with numerous players offering a diverse range of products to meet the varying needs of the oil and gas industry. As the industry continues to evolve, the demand for advanced wax inhibitors is expected to grow, driven by the need for more efficient and sustainable flow assurance solutions.

Crude Oil Transportation, Crude Oil Processing, Others in the Global Wax Inhibitor Market:

The usage of wax inhibitors in the Global Wax Inhibitor Market is crucial in several areas, including crude oil transportation, crude oil processing, and other related applications. In crude oil transportation, wax inhibitors play a vital role in ensuring the smooth flow of oil through pipelines. As crude oil is transported from extraction sites to refineries, it often passes through regions with varying temperatures. In colder climates, the risk of wax formation increases, leading to potential blockages in the pipelines. Wax inhibitors prevent this by modifying the wax crystal structure, ensuring that the oil remains fluid and can be transported efficiently. This not only reduces the risk of pipeline blockages but also minimizes the need for costly maintenance and repairs. In crude oil processing, wax inhibitors are used to enhance the efficiency of refining operations. During the refining process, crude oil is subjected to various temperature and pressure conditions, which can lead to the formation of wax deposits. These deposits can hinder the refining process, reducing the overall efficiency and increasing operational costs. By using wax inhibitors, refineries can prevent the formation of wax deposits, ensuring a smoother and more efficient refining process. This not only improves the quality of the refined products but also reduces the energy consumption and environmental impact of the refining operations. In addition to transportation and processing, wax inhibitors are also used in other applications within the oil and gas industry. For example, they are used in the storage of crude oil, where they help maintain the fluidity of the oil, preventing the formation of wax deposits in storage tanks. This is particularly important in regions with fluctuating temperatures, where the risk of wax formation is higher. Wax inhibitors are also used in enhanced oil recovery techniques, where they help improve the flow of oil from the reservoir to the surface. By preventing wax formation, these inhibitors enhance the efficiency of the recovery process, increasing the overall yield of the extraction operations. The use of wax inhibitors in these various applications highlights their importance in the oil and gas industry, where they play a crucial role in ensuring the efficient and sustainable production, transportation, and processing of crude oil. As the demand for energy continues to rise, the need for effective wax inhibitors is expected to grow, driving innovation and development in the Global Wax Inhibitor Market.

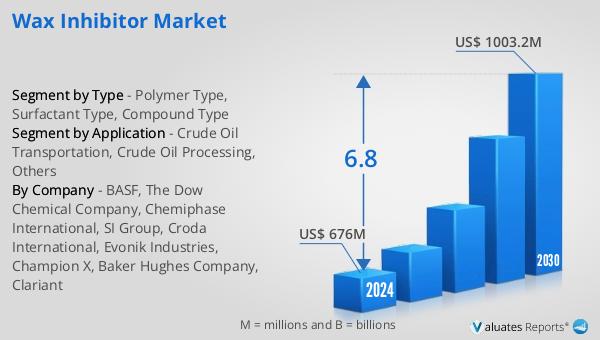

Global Wax Inhibitor Market Outlook:

The outlook for the Global Wax Inhibitor Market indicates a promising growth trajectory, with projections showing an increase from $676 million in 2024 to $1003.2 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period. This growth is driven by the increasing demand for efficient crude oil transportation and processing solutions, as well as the expanding oil exploration and production activities worldwide. However, the market has faced challenges, particularly in 2020, when the size of the petrochemicals market declined to $422 billion, marking a year-on-year decrease of 4.3%. This decline was attributed to the fall in crude oil prices and shrinking downstream demand, which significantly narrowed the overall profit margins of the petrochemicals industry. As a result, several enterprises incurred losses, highlighting the volatility and challenges faced by the industry. Despite these challenges, the Global Wax Inhibitor Market is expected to recover and grow, driven by technological advancements and the increasing complexity of oil extraction processes. Companies in the market are investing in research and development to create more effective and environmentally friendly solutions, ensuring the continued growth and sustainability of the industry.

| Report Metric | Details |

| Report Name | Wax Inhibitor Market |

| Accounted market size in 2024 | US$ 676 in million |

| Forecasted market size in 2030 | US$ 1003.2 million |

| CAGR | 6.8 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | BASF, The Dow Chemical Company, Chemiphase International, SI Group, Croda International, Evonik Industries, Champion X, Baker Hughes Company, Clariant |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |