What is Global Noise and Vibration Coatings Market?

The Global Noise and Vibration Coatings Market is a specialized segment within the broader coatings industry, focusing on products designed to reduce noise and vibration in various applications. These coatings are essential in industries where noise reduction and vibration control are critical for operational efficiency and comfort. They are used in automotive, marine, industrial machinery, and other sectors to enhance the performance and longevity of equipment by minimizing the adverse effects of noise and vibration. The market for these coatings is driven by the increasing demand for quieter and more efficient machinery and vehicles, as well as stringent regulations regarding noise pollution. Technological advancements and the development of new materials have also contributed to the growth of this market, offering more effective and durable solutions for noise and vibration control.

Acrylic Based, PTFE Based, Rubber Based, Others in the Global Noise and Vibration Coatings Market:

Acrylic-based noise and vibration coatings are widely used due to their excellent adhesion properties, flexibility, and durability. These coatings are particularly effective in reducing noise and vibration in automotive and industrial applications. They form a protective layer that absorbs sound waves and dampens vibrations, thereby enhancing the performance and lifespan of the equipment. PTFE-based coatings, on the other hand, are known for their exceptional resistance to heat, chemicals, and wear. These properties make them ideal for use in harsh environments where equipment is exposed to extreme conditions. PTFE-based coatings provide a smooth, non-stick surface that reduces friction and noise, making them suitable for applications in the automotive, aerospace, and industrial sectors. Rubber-based coatings are another popular choice for noise and vibration control. These coatings are highly flexible and resilient, providing excellent damping properties. They are commonly used in automotive and industrial applications to reduce noise and vibration in engines, machinery, and other equipment. Rubber-based coatings also offer good resistance to abrasion and impact, making them suitable for use in demanding environments. Other types of noise and vibration coatings include polyurethane, epoxy, and silicone-based coatings. Polyurethane coatings are known for their excellent abrasion resistance and flexibility, making them ideal for use in automotive and industrial applications. Epoxy coatings offer superior adhesion and chemical resistance, making them suitable for use in harsh environments. Silicone-based coatings provide excellent thermal stability and flexibility, making them ideal for use in high-temperature applications. Each type of coating has its unique properties and advantages, making them suitable for different applications and environments.

Automotive, Marine, Appliances, Duct Work, Industrial Machinery, Others in the Global Noise and Vibration Coatings Market:

The Global Noise and Vibration Coatings Market finds extensive usage in various sectors, including automotive, marine, appliances, duct work, industrial machinery, and others. In the automotive industry, these coatings are used to reduce noise and vibration in engines, transmissions, and other components, enhancing the overall driving experience and vehicle performance. They help in minimizing the noise generated by moving parts and vibrations caused by road conditions, thereby improving the comfort and safety of the vehicle. In the marine sector, noise and vibration coatings are used to reduce the noise generated by engines, propellers, and other machinery, enhancing the comfort and safety of passengers and crew. These coatings also help in protecting the equipment from corrosion and wear, thereby extending their lifespan. In the appliances sector, noise and vibration coatings are used to reduce the noise generated by household appliances such as washing machines, refrigerators, and air conditioners. These coatings help in improving the performance and longevity of the appliances by minimizing the adverse effects of noise and vibration. In duct work, noise and vibration coatings are used to reduce the noise generated by air flow and mechanical vibrations in HVAC systems, enhancing the comfort and efficiency of the building. In industrial machinery, noise and vibration coatings are used to reduce the noise and vibration generated by engines, pumps, compressors, and other equipment, improving the performance and lifespan of the machinery. These coatings also help in protecting the equipment from wear and corrosion, thereby reducing maintenance costs and downtime. Other applications of noise and vibration coatings include construction, aerospace, and electronics, where they are used to reduce noise and vibration in various equipment and systems.

Global Noise and Vibration Coatings Market Outlook:

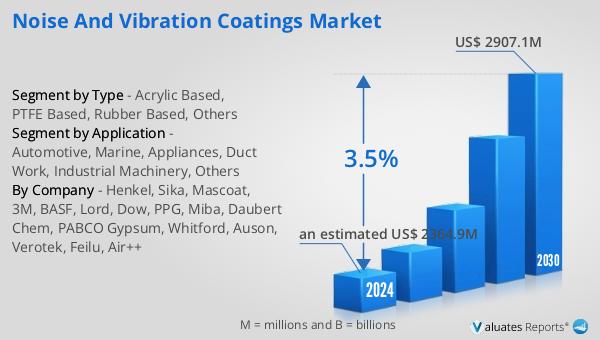

The global Noise and Vibration Coatings market is anticipated to grow significantly, reaching an estimated value of US$ 2907.1 million by 2030, up from US$ 2364.9 million in 2024. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% between 2024 and 2030. In 2019, the top 10 manufacturers in this market collectively held about 67.54% of the market share, indicating a high level of market concentration. This suggests that a few key players dominate the market, leveraging their technological advancements, extensive distribution networks, and strong brand recognition to maintain their competitive edge. The market's growth is driven by increasing demand for noise and vibration control solutions across various industries, including automotive, marine, industrial machinery, and others. As industries continue to prioritize operational efficiency, safety, and comfort, the demand for effective noise and vibration coatings is expected to rise. Additionally, stringent regulations regarding noise pollution and the need for quieter and more efficient machinery and vehicles are likely to further propel the market's growth. Technological advancements and the development of new materials are also expected to contribute to the market's expansion, offering more effective and durable solutions for noise and vibration control.

| Report Metric | Details |

| Report Name | Noise and Vibration Coatings Market |

| Accounted market size in 2024 | an estimated US$ 2364.9 million |

| Forecasted market size in 2030 | US$ 2907.1 million |

| CAGR | 3.5% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, Sika, Mascoat, 3M, BASF, Lord, Dow, PPG, Miba, Daubert Chem, PABCO Gypsum, Whitford, Auson, Verotek, Feilu, Air++ |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |