What is Global Machine Protection Systems (MPS) Market?

The Global Machine Protection Systems (MPS) Market refers to the industry focused on the development, production, and implementation of systems designed to protect machinery and equipment from damage, malfunction, or failure. These systems are crucial in ensuring the longevity and efficiency of machines used across various industries. Machine protection systems encompass a wide range of technologies and solutions, including sensors, control systems, and software, all aimed at monitoring and safeguarding machinery. The primary goal of MPS is to prevent costly downtime, reduce maintenance expenses, and enhance overall operational safety. As industries continue to adopt automation and advanced machinery, the demand for robust machine protection systems is expected to grow, driven by the need for increased productivity and reduced operational risks. The market for MPS is global, with significant contributions from regions such as North America, Europe, Asia-Pacific, and others, reflecting the widespread adoption of these systems across different industrial sectors.

Software, Hardware in the Global Machine Protection Systems (MPS) Market:

In the realm of Global Machine Protection Systems (MPS), both software and hardware components play pivotal roles in ensuring the effective protection and optimal performance of machinery. Hardware components in MPS include sensors, actuators, control units, and other physical devices that are installed on or around machinery to monitor various parameters such as temperature, pressure, vibration, and speed. These sensors collect real-time data, which is then processed by control units to detect any anomalies or potential issues. For instance, vibration sensors can detect unusual vibrations that may indicate mechanical problems, while temperature sensors can monitor overheating conditions. Actuators, on the other hand, are responsible for executing corrective actions, such as shutting down a machine or adjusting its operating parameters to prevent damage. Software components in MPS are equally crucial, as they provide the intelligence and analytical capabilities needed to interpret the data collected by hardware sensors. Advanced software solutions use algorithms and machine learning techniques to analyze data, identify patterns, and predict potential failures before they occur. This predictive maintenance approach allows industries to address issues proactively, minimizing downtime and extending the lifespan of machinery. Software platforms also offer user-friendly interfaces that enable operators to monitor machine health in real-time, receive alerts, and generate reports for maintenance planning. Additionally, software integration with other industrial systems, such as SCADA (Supervisory Control and Data Acquisition) and ERP (Enterprise Resource Planning), ensures seamless communication and coordination across different operational areas. The synergy between hardware and software in MPS is essential for creating a comprehensive protection system. For example, in a manufacturing plant, hardware sensors might detect an increase in vibration levels in a critical machine. The software then analyzes this data, compares it with historical trends, and determines that the machine is likely to fail within a certain timeframe. The system can then alert maintenance personnel, who can schedule a repair before the machine breaks down, thus avoiding costly production halts. This integration of hardware and software not only enhances machine reliability but also contributes to overall operational efficiency and cost savings. Moreover, advancements in technology are continuously improving the capabilities of both hardware and software components in MPS. The development of IoT (Internet of Things) has enabled more sophisticated and interconnected sensor networks, allowing for more comprehensive monitoring and data collection. On the software side, the use of artificial intelligence and big data analytics is enhancing the predictive accuracy and decision-making capabilities of machine protection systems. These technological advancements are driving the evolution of MPS, making them more effective and accessible to a wider range of industries. In conclusion, the Global Machine Protection Systems (MPS) Market relies on the harmonious integration of hardware and software components to safeguard machinery and ensure optimal performance. Hardware sensors and actuators provide the necessary data and physical interventions, while software solutions offer the analytical power and predictive insights needed for proactive maintenance. Together, they form a robust system that enhances machine reliability, reduces downtime, and contributes to overall operational efficiency. As technology continues to advance, the capabilities of MPS will only improve, further solidifying their importance in various industrial sectors.

Transportation Industry, Manufacturing, Oil and Gas, Chemical Industry, Others in the Global Machine Protection Systems (MPS) Market:

The usage of Global Machine Protection Systems (MPS) Market spans across various industries, each benefiting from the enhanced safety, reliability, and efficiency that these systems provide. In the transportation industry, MPS plays a critical role in ensuring the smooth operation of vehicles, trains, and aircraft. For instance, sensors and control systems monitor the condition of engines, brakes, and other critical components, detecting any signs of wear or malfunction. This real-time monitoring allows for timely maintenance and repairs, preventing accidents and reducing downtime. In railways, MPS can monitor track conditions and train systems, ensuring safe and efficient operations. Similarly, in aviation, these systems help maintain the health of aircraft engines and other vital systems, enhancing safety and reliability. In the manufacturing sector, MPS is indispensable for maintaining the efficiency and productivity of production lines. Manufacturing processes often involve complex machinery that operates continuously, making it essential to monitor their condition and performance. MPS systems use sensors to track parameters such as temperature, pressure, and vibration, identifying any deviations from normal operating conditions. This data is then analyzed by software to predict potential failures and schedule preventive maintenance. By doing so, manufacturers can avoid unexpected breakdowns, reduce maintenance costs, and ensure consistent product quality. Additionally, MPS can help optimize machine performance, leading to increased production efficiency and reduced energy consumption. The oil and gas industry also relies heavily on MPS to ensure the safe and efficient operation of its equipment. This industry involves the use of heavy machinery and complex systems in harsh and often remote environments. MPS systems monitor the condition of drilling rigs, pipelines, and processing equipment, detecting any signs of wear, corrosion, or malfunction. By providing real-time data and predictive insights, these systems enable operators to address issues before they escalate, preventing costly downtime and environmental hazards. In addition, MPS can enhance the safety of oil and gas operations by monitoring critical parameters and triggering automatic shutdowns in case of emergencies. In the chemical industry, MPS is crucial for maintaining the safety and efficiency of chemical processing plants. These plants involve the handling of hazardous materials and complex chemical reactions, making it essential to monitor equipment conditions closely. MPS systems track parameters such as pressure, temperature, and flow rates, ensuring that equipment operates within safe limits. Any deviations are detected and addressed promptly, preventing accidents and ensuring compliance with safety regulations. Furthermore, MPS can help optimize chemical processes, improving product quality and reducing waste. Other industries, such as power generation, mining, and pharmaceuticals, also benefit from the use of MPS. In power generation, MPS systems monitor the condition of turbines, generators, and other critical equipment, ensuring reliable and efficient power production. In mining, these systems help maintain the health of heavy machinery and ensure safe operations in challenging environments. In the pharmaceutical industry, MPS ensures the reliability of manufacturing equipment, maintaining product quality and compliance with regulatory standards. In summary, the Global Machine Protection Systems (MPS) Market finds applications across a wide range of industries, each benefiting from the enhanced safety, reliability, and efficiency that these systems provide. From transportation and manufacturing to oil and gas, chemical, and other industries, MPS plays a vital role in ensuring the smooth operation of machinery and equipment. By providing real-time monitoring, predictive insights, and timely interventions, these systems help prevent costly downtime, reduce maintenance expenses, and enhance overall operational safety. As industries continue to adopt advanced machinery and automation, the importance of MPS will only grow, driving further demand for these essential systems.

Global Machine Protection Systems (MPS) Market Outlook:

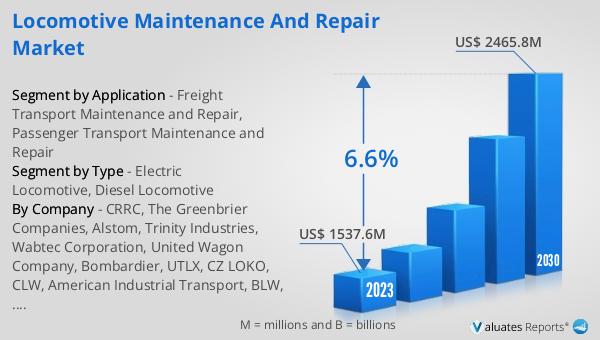

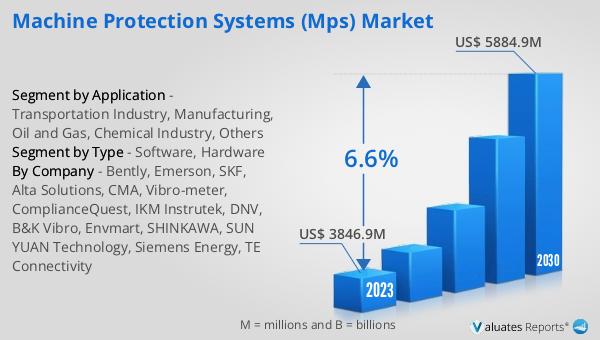

The global Machine Protection Systems (MPS) market was valued at US$ 3846.9 million in 2023 and is anticipated to reach US$ 5884.9 million by 2030, witnessing a CAGR of 6.6% during the forecast period 2024-2030. This significant growth reflects the increasing demand for advanced machine protection solutions across various industries. As companies strive to enhance operational efficiency, reduce downtime, and ensure the safety of their machinery, the adoption of MPS is expected to rise. The market's expansion is driven by technological advancements, such as the integration of IoT and AI, which are enhancing the capabilities of MPS systems. Additionally, the growing emphasis on predictive maintenance and the need to comply with stringent safety regulations are further propelling the market's growth. With the continuous development of innovative solutions and the rising awareness of the benefits of MPS, the market is poised for substantial growth in the coming years.

| Report Metric | Details |

| Report Name | Machine Protection Systems (MPS) Market |

| Accounted market size in 2023 | US$ 3846.9 million |

| Forecasted market size in 2030 | US$ 5884.9 million |

| CAGR | 6.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bently, Emerson, SKF, Alta Solutions, CMA, Vibro-meter, ComplianceQuest, IKM Instrutek, DNV, B&K Vibro, Envmart, SHINKAWA, SUN YUAN Technology, Siemens Energy, TE Connectivity |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |