What is Global Locomotive Maintenance and Repair Market?

The Global Locomotive Maintenance and Repair Market refers to the industry focused on the upkeep and restoration of locomotives, which are the engines that pull trains. This market encompasses a wide range of services, including routine inspections, part replacements, overhauls, and emergency repairs. The goal is to ensure that locomotives operate efficiently, safely, and reliably. Maintenance and repair services are crucial for extending the lifespan of locomotives, reducing downtime, and preventing costly breakdowns. The market serves various types of locomotives, including electric, diesel, and hybrid models, and caters to both freight and passenger transport sectors. With the increasing demand for rail transport due to its cost-effectiveness and environmental benefits, the locomotive maintenance and repair market is expected to grow steadily. Technological advancements, such as the integration of digital tools and predictive maintenance techniques, are also playing a significant role in shaping the future of this market.

Electric Locomotive, Diesel Locomotive in the Global Locomotive Maintenance and Repair Market:

Electric locomotives and diesel locomotives are two primary types of engines that require distinct maintenance and repair services within the Global Locomotive Maintenance and Repair Market. Electric locomotives are powered by electricity, typically drawn from overhead lines or electrified rails. They are known for their high efficiency, lower emissions, and reduced noise levels compared to diesel locomotives. Maintenance for electric locomotives often involves checking and servicing electrical components, such as transformers, traction motors, and control systems. Regular inspections are necessary to ensure that the electrical systems are functioning correctly and to prevent issues like short circuits or power losses. Additionally, the maintenance of pantographs, which are the devices that collect power from overhead lines, is crucial to ensure a continuous power supply. On the other hand, diesel locomotives are powered by diesel engines and are more versatile as they do not require an electrified track. They are commonly used in regions where electrification is not feasible or cost-effective. Diesel locomotive maintenance involves servicing the engine, fuel system, and exhaust system. Regular oil changes, filter replacements, and inspections of the fuel injectors and turbochargers are essential to keep the diesel engines running smoothly. Additionally, the cooling system, which prevents the engine from overheating, requires regular checks and maintenance. Diesel locomotives also have complex mechanical systems, including gearboxes and drive shafts, which need periodic lubrication and inspection to ensure optimal performance. Both electric and diesel locomotives benefit from advancements in digital technologies and predictive maintenance. Sensors and IoT devices can be installed on locomotives to monitor various parameters in real-time, such as temperature, vibration, and pressure. This data can be analyzed to predict potential failures and schedule maintenance proactively, reducing the risk of unexpected breakdowns and improving overall efficiency. For instance, predictive maintenance can help identify issues like worn-out bearings or electrical faults before they lead to significant problems. By integrating digital tools, the maintenance and repair process becomes more efficient, cost-effective, and reliable. In summary, the Global Locomotive Maintenance and Repair Market plays a vital role in ensuring the smooth operation of both electric and diesel locomotives. While electric locomotives require specialized maintenance for their electrical systems, diesel locomotives need regular servicing of their engines and mechanical components. The adoption of digital technologies and predictive maintenance is enhancing the efficiency and reliability of maintenance services, contributing to the growth and development of the market.

Freight Transport Maintenance and Repair, Passenger Transport Maintenance and Repair in the Global Locomotive Maintenance and Repair Market:

The Global Locomotive Maintenance and Repair Market is essential for both freight and passenger transport sectors, ensuring that locomotives remain in optimal condition to meet the demands of these services. In the freight transport sector, locomotives are responsible for hauling heavy loads over long distances, making their reliability and efficiency crucial. Regular maintenance and repair services help prevent breakdowns that could disrupt supply chains and cause significant financial losses. Freight locomotives often operate in harsh conditions, such as extreme temperatures and rough terrains, which can accelerate wear and tear. Therefore, routine inspections, part replacements, and overhauls are necessary to keep these locomotives in top condition. Maintenance tasks may include checking the integrity of the chassis, inspecting the braking systems, and ensuring that the coupling mechanisms are functioning correctly. Additionally, freight locomotives may require specialized services, such as wheel truing and alignment, to ensure smooth and safe operation. In the passenger transport sector, the focus is on providing a safe, comfortable, and timely travel experience for passengers. Locomotive maintenance and repair services are critical to achieving this goal. Passenger locomotives often operate on tight schedules and require high levels of reliability to avoid delays and cancellations. Regular maintenance helps ensure that these locomotives are in peak condition, minimizing the risk of mechanical failures that could inconvenience passengers. Key maintenance tasks for passenger locomotives include inspecting and servicing the HVAC systems to ensure passenger comfort, checking the safety systems such as automatic train control and signaling equipment, and maintaining the cleanliness and functionality of the interior components. Additionally, passenger locomotives may require periodic upgrades to meet evolving safety standards and passenger expectations. Both freight and passenger transport sectors benefit from the integration of digital technologies and predictive maintenance in the Global Locomotive Maintenance and Repair Market. By using sensors and IoT devices to monitor locomotive performance in real-time, maintenance teams can identify potential issues before they become critical. For example, sensors can detect abnormal vibrations or temperature fluctuations, indicating that a component may be nearing failure. This allows for timely interventions, reducing the risk of unexpected breakdowns and improving overall operational efficiency. Predictive maintenance also helps optimize maintenance schedules, ensuring that locomotives are serviced at the most appropriate times to minimize downtime and maximize availability. In conclusion, the Global Locomotive Maintenance and Repair Market is vital for the smooth operation of both freight and passenger transport services. Regular maintenance and repair services help ensure that locomotives remain reliable, efficient, and safe, minimizing disruptions and enhancing the overall travel experience. The adoption of digital technologies and predictive maintenance is further improving the efficiency and effectiveness of maintenance services, contributing to the growth and development of the market.

Global Locomotive Maintenance and Repair Market Outlook:

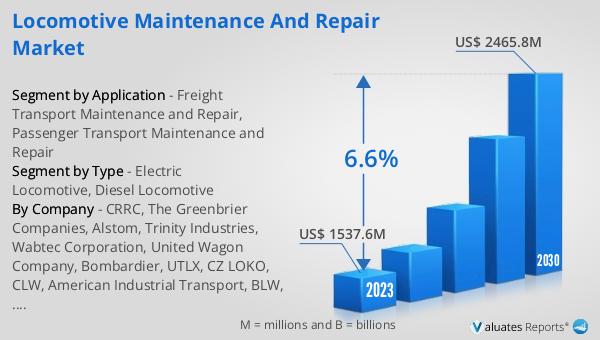

The global Locomotive Maintenance and Repair market was valued at US$ 1537.6 million in 2023 and is anticipated to reach US$ 2465.8 million by 2030, witnessing a CAGR of 6.6% during the forecast period from 2024 to 2030. This growth is driven by the increasing integration of digital technologies and predictive maintenance techniques. By incorporating sensors and IoT devices, the industry can monitor locomotive performance in real-time, allowing for more efficient and proactive maintenance strategies. These digital tools enable the collection and analysis of vast amounts of data, helping to predict potential failures and schedule maintenance activities before issues become critical. This not only reduces downtime and maintenance costs but also enhances the overall reliability and efficiency of locomotive operations. As a result, the market is expected to continue its upward trajectory, driven by technological advancements and the growing demand for efficient and reliable rail transport services.

| Report Metric | Details |

| Report Name | Locomotive Maintenance and Repair Market |

| Accounted market size in 2023 | US$ 1537.6 million |

| Forecasted market size in 2030 | US$ 2465.8 million |

| CAGR | 6.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | CRRC, The Greenbrier Companies, Alstom, Trinity Industries, Wabtec Corporation, United Wagon Company, Bombardier, UTLX, CZ LOKO, CLW, American Industrial Transport, BLW, Buckingham Branch Railroad, Siemens Mobility, GATX Corporation, Hitachi Rail, Progress Rail, Stadler Rail, Titagarh Wagons, CAD Railway Industries, Hyundai Motor Group, McHugh Locomotive & Equipment, Inter Rail Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |