What is Global 5-axis DCVMC Market?

The Global 5-axis DCVMC (Double Column Vertical Machining Center) Market represents a significant segment within the broader machine tool industry, focusing on advanced machining solutions that offer enhanced precision and efficiency. These machines are designed to perform complex and intricate machining tasks by allowing simultaneous movement along five different axes. This capability is crucial for industries that require high precision and intricate detailing, such as aerospace, automotive, and medical device manufacturing. The 5-axis DCVMCs are particularly valued for their ability to reduce setup time and improve the accuracy of complex parts, which is essential in maintaining competitive advantage in high-tech manufacturing sectors. The market for these machines is driven by the increasing demand for high-quality, precision-engineered components, as well as the need for more efficient production processes. As industries continue to evolve and demand more sophisticated products, the role of 5-axis DCVMCs becomes increasingly important, making this market a critical area of focus for manufacturers and investors alike. The growth of this market is also supported by technological advancements that enhance the capabilities of these machines, making them more versatile and efficient.

Dual Rotary Table, Combined Rotary Table and Swing Head, Dual Swing Head in the Global 5-axis DCVMC Market:

In the Global 5-axis DCVMC Market, various configurations such as Dual Rotary Table, Combined Rotary Table and Swing Head, and Dual Swing Head play pivotal roles in enhancing the versatility and functionality of machining centers. The Dual Rotary Table configuration is particularly advantageous for operations requiring simultaneous multi-axis machining. This setup allows for the rotation of the workpiece along two axes, providing greater flexibility and precision in machining complex geometries. It is especially beneficial in industries like aerospace and automotive, where intricate parts with complex curves and angles are common. The Combined Rotary Table and Swing Head configuration offers a unique blend of capabilities by integrating the rotational movement of the table with the swinging motion of the head. This combination allows for a broader range of motion and access to the workpiece, enabling the machining of parts with challenging geometries that would otherwise be difficult to achieve. This setup is ideal for applications that require both high precision and adaptability to various part shapes and sizes. On the other hand, the Dual Swing Head configuration provides an alternative approach by allowing the machining head to pivot along two axes. This setup is particularly useful for operations that require extensive reach and flexibility, such as machining large components or parts with deep cavities. The dual swing head design enhances the machine's ability to access hard-to-reach areas, making it a preferred choice for industries that deal with large-scale or complex parts. Each of these configurations offers distinct advantages, and the choice between them depends on the specific requirements of the machining task at hand. The ability to choose from these configurations allows manufacturers to tailor their machining processes to meet the precise needs of their production lines, thereby optimizing efficiency and output quality. As the demand for more complex and precise components continues to grow, the importance of these configurations in the Global 5-axis DCVMC Market is expected to increase, driving further innovation and development in this field.

Aerospace & Defense, Automotive, Heavy Machinery, Energy, Others in the Global 5-axis DCVMC Market:

The Global 5-axis DCVMC Market finds extensive applications across various industries, including Aerospace & Defense, Automotive, Heavy Machinery, Energy, and others, due to its ability to deliver high precision and efficiency in machining complex parts. In the Aerospace & Defense sector, 5-axis DCVMCs are indispensable for manufacturing critical components such as turbine blades, engine parts, and structural components that require intricate detailing and tight tolerances. The ability to machine complex geometries with high precision is crucial in this industry, where safety and performance are paramount. Similarly, in the Automotive industry, these machines are used to produce engine components, transmission parts, and other critical components that demand high precision and consistency. The automotive sector benefits from the reduced setup times and increased accuracy offered by 5-axis DCVMCs, which contribute to improved production efficiency and product quality. In the Heavy Machinery industry, the ability to machine large and complex parts with precision is essential, and 5-axis DCVMCs provide the necessary capabilities to meet these demands. These machines are used to produce components for construction equipment, mining machinery, and other heavy-duty applications where durability and precision are critical. The Energy sector also relies on 5-axis DCVMCs for manufacturing components used in power generation, such as turbine blades and other critical parts that require high precision and reliability. The versatility and precision of these machines make them ideal for producing components that must withstand extreme conditions and perform reliably over long periods. Beyond these industries, 5-axis DCVMCs are also used in various other sectors, including medical device manufacturing, where precision and quality are of utmost importance. The ability to produce complex and intricate parts with high accuracy makes these machines invaluable in industries where precision and quality are critical. As industries continue to evolve and demand more sophisticated products, the role of 5-axis DCVMCs in these sectors is expected to grow, driving further innovation and development in the Global 5-axis DCVMC Market.

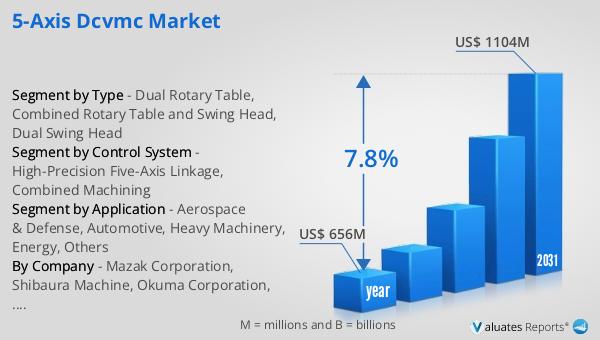

Global 5-axis DCVMC Market Outlook:

The global market for 5-axis DCVMCs was valued at approximately $656 million in 2024, and projections indicate that it will expand to a revised size of around $1,104 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.8% over the forecast period. This upward trajectory underscores the increasing demand for advanced machining solutions that offer enhanced precision and efficiency across various industries. The growth of this market is driven by several factors, including the rising demand for high-quality, precision-engineered components and the need for more efficient production processes. As industries continue to evolve and demand more sophisticated products, the role of 5-axis DCVMCs becomes increasingly important, making this market a critical area of focus for manufacturers and investors alike. The growth of this market is also supported by technological advancements that enhance the capabilities of these machines, making them more versatile and efficient. As a result, the Global 5-axis DCVMC Market is poised for significant growth in the coming years, driven by the increasing demand for advanced machining solutions across various industries.

| Report Metric | Details |

| Report Name | 5-axis DCVMC Market |

| Accounted market size in year | US$ 656 million |

| Forecasted market size in 2031 | US$ 1104 million |

| CAGR | 7.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Control System |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mazak Corporation, Shibaura Machine, Okuma Corporation, DN Solutions, Haitian Precision, Mitsubishi Heavy Industries, JTEKT, DMG MORI, Danobat, Shenzhen Create Century Machinery, SNK, Weihai Huadong Automation, Neway Valve (Suzhou), Fidia S.p.A., AWEA, Kitamura Machinery, Starvision Machinery, Hurco Companies, Nantong Guosheng Intelligence Technology Group, Jirfine Intelligent Equipment, Pratic CNC, Qinchuan Machine Tool & Tool Group Share, Zhejiang RIFA Precision Machinery, Nicolás Correa, YCM (Yeong Chin Machinery Industries Co., Ltd.), Campro Precision Machinery, Litz Hitech Corp. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |