What is Global Concrete Sleepers Market?

The Global Concrete Sleepers Market refers to the worldwide industry focused on the production and distribution of concrete sleepers, which are essential components in railway infrastructure. Concrete sleepers, also known as railroad ties, are used to support the rails in railway tracks, providing stability and durability. These sleepers are made from concrete, a material chosen for its strength, longevity, and resistance to environmental factors such as moisture and temperature changes. The market for concrete sleepers is driven by the ongoing expansion and modernization of railway networks across the globe, as countries invest in improving their transportation infrastructure to support economic growth and urbanization. Additionally, the shift towards high-speed rail systems and the need for sustainable and low-maintenance track solutions further fuel the demand for concrete sleepers. The market encompasses various types of concrete sleepers, including reinforced and prestressed variants, each designed to meet specific performance requirements. As the global transportation landscape evolves, the concrete sleepers market is expected to continue its growth trajectory, driven by technological advancements and increasing investments in rail infrastructure projects.

Reinforced Concrete Sleepers, Prestressed Reinforced Concrete Sleepers in the Global Concrete Sleepers Market:

Reinforced concrete sleepers and prestressed reinforced concrete sleepers are two key types of sleepers used in the Global Concrete Sleepers Market, each offering distinct advantages and applications. Reinforced concrete sleepers are constructed using steel reinforcement bars embedded within the concrete, providing additional strength and durability. This reinforcement helps the sleepers withstand the dynamic loads and stresses imposed by passing trains, ensuring the stability and safety of the railway tracks. Reinforced concrete sleepers are widely used in conventional railway systems, where they offer a cost-effective and reliable solution for track support. On the other hand, prestressed reinforced concrete sleepers are designed to handle even greater loads and stresses. These sleepers are manufactured using a process called prestressing, where high-strength steel tendons are tensioned before the concrete is poured. Once the concrete sets, the tension is released, compressing the concrete and enhancing its load-bearing capacity. This process results in sleepers that are exceptionally strong and resistant to cracking, making them ideal for high-speed rail systems and heavy freight lines. Prestressed reinforced concrete sleepers are favored in applications where superior performance and longevity are critical, such as in high-speed rail networks and areas with challenging environmental conditions. The choice between reinforced and prestressed reinforced concrete sleepers depends on various factors, including the specific requirements of the railway project, the expected load and traffic conditions, and the budget constraints. Both types of sleepers contribute significantly to the overall efficiency and safety of railway operations, ensuring smooth and reliable train movements. As the demand for efficient and sustainable rail infrastructure continues to grow, the Global Concrete Sleepers Market is expected to witness increased adoption of both reinforced and prestressed reinforced concrete sleepers, driven by advancements in manufacturing technologies and the need for durable and low-maintenance track solutions.

Railway, Mine, Others in the Global Concrete Sleepers Market:

The Global Concrete Sleepers Market plays a crucial role in various sectors, including railway, mining, and other industries, by providing essential infrastructure components that enhance operational efficiency and safety. In the railway sector, concrete sleepers are indispensable for constructing and maintaining railway tracks. They provide a stable and durable foundation for the rails, ensuring smooth and safe train operations. Concrete sleepers are preferred over traditional wooden sleepers due to their superior strength, longevity, and resistance to environmental factors such as moisture, temperature fluctuations, and pests. This makes them ideal for use in both conventional and high-speed rail systems, where reliability and performance are paramount. In the mining industry, concrete sleepers are used to support rail tracks within mining sites, facilitating the transportation of extracted materials. The robust nature of concrete sleepers makes them well-suited for the harsh conditions often encountered in mining environments, where heavy loads and abrasive materials can cause significant wear and tear on infrastructure. By providing a durable and low-maintenance track solution, concrete sleepers help mining operations maintain efficient and safe material transport, ultimately contributing to increased productivity and reduced operational costs. Beyond railway and mining applications, concrete sleepers are also utilized in various other industries where rail transport is essential. For instance, they are used in ports and logistics hubs to support rail tracks that facilitate the movement of goods and materials. Additionally, concrete sleepers are employed in industrial facilities and manufacturing plants where rail systems are used for internal material handling and transportation. The versatility and durability of concrete sleepers make them a preferred choice for these applications, ensuring reliable and efficient rail operations across diverse sectors. As the demand for efficient and sustainable transportation solutions continues to grow, the Global Concrete Sleepers Market is poised to expand its reach across various industries, driven by the need for durable and low-maintenance track infrastructure.

Global Concrete Sleepers Market Outlook:

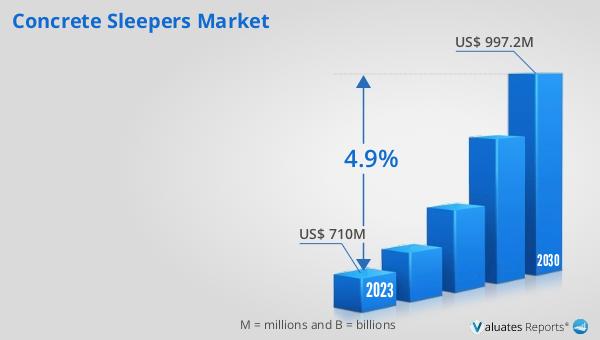

In 2024, the global market for concrete sleepers was valued at approximately $781 million. This market is anticipated to grow significantly, reaching an estimated size of $1,087 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.9% over the forecast period. The increasing demand for concrete sleepers is driven by the expansion and modernization of railway networks worldwide, as countries invest in improving their transportation infrastructure to support economic growth and urbanization. Additionally, the shift towards high-speed rail systems and the need for sustainable and low-maintenance track solutions further fuel the demand for concrete sleepers. The market encompasses various types of concrete sleepers, including reinforced and prestressed variants, each designed to meet specific performance requirements. As the global transportation landscape evolves, the concrete sleepers market is expected to continue its growth trajectory, driven by technological advancements and increasing investments in rail infrastructure projects. This growth is indicative of the critical role that concrete sleepers play in supporting the development of efficient and sustainable transportation systems across the globe.

| Report Metric | Details |

| Report Name | Concrete Sleepers Market |

| Accounted market size in year | US$ 781 million |

| Forecasted market size in 2031 | US$ 1087 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Abetong, Kirchdorfer Group, Austrak, Patil Group, Aveng Infraset, The Indian Hume Pipe, Shandong High Speed Rail Equipment Material, Weihai Ruihe Railway Sleeper, Hengchang Railroad Sleeper, Kunming Railway Sleeper, Guangxi Sanwei Rail Manufacturing Co., Voestalpine, Rocla, Plastwil, Leonhard Moll Betonwerke GmbH & Co KG, Colossal Concrete Products, Gilada Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |