What is Global Air-Operated Pinch Valve Market?

The Global Air-Operated Pinch Valve Market is a specialized segment within the broader industrial valve market, focusing on valves that use compressed air to control the flow of various media through a flexible tube or sleeve. These valves are particularly valued for their ability to handle abrasive, corrosive, and viscous materials without causing damage to the valve itself, as the media does not come into contact with any metal parts. This makes them ideal for applications in industries such as mining, chemical processing, and wastewater management, where the materials being transported can be particularly harsh. The market for these valves is driven by the need for efficient and reliable flow control solutions that can withstand challenging operating conditions. As industries continue to seek ways to improve operational efficiency and reduce maintenance costs, the demand for air-operated pinch valves is expected to grow. These valves offer a cost-effective solution by minimizing downtime and extending the lifespan of the system components they are integrated with. The market is characterized by a diverse range of products, with variations in size, material, and design to suit different industrial requirements.

Switch Type, Regulation Type in the Global Air-Operated Pinch Valve Market:

In the Global Air-Operated Pinch Valve Market, the switch type and regulation type are critical factors that influence the functionality and application of these valves. Switch types in air-operated pinch valves refer to the mechanisms used to control the opening and closing of the valve. These can include manual switches, which require human intervention to operate, and automated switches, which can be controlled remotely or programmed to operate based on specific conditions. Automated switches are increasingly popular in modern industrial settings due to their ability to enhance efficiency and reduce the need for manual labor. They can be integrated with advanced control systems to provide precise flow regulation and monitoring, which is essential in industries where accuracy and reliability are paramount. Regulation type, on the other hand, pertains to how the flow of media through the valve is controlled. This can be achieved through various methods, such as throttling, which allows for gradual adjustment of flow, or on/off regulation, which provides a simple open or closed state. Throttling is particularly useful in applications where the flow rate needs to be adjusted frequently or maintained at a specific level, while on/off regulation is suitable for applications where the flow needs to be completely stopped or started. The choice of switch type and regulation type depends on several factors, including the nature of the media being transported, the operating environment, and the specific requirements of the application. For instance, in environments where safety is a concern, automated switches with remote control capabilities may be preferred to minimize human exposure to hazardous conditions. Similarly, in applications where precise flow control is necessary, throttling regulation may be more appropriate. The integration of advanced technologies, such as sensors and control systems, is also playing a significant role in the evolution of switch and regulation types in the air-operated pinch valve market. These technologies enable real-time monitoring and control of valve operations, providing valuable data that can be used to optimize performance and reduce maintenance costs. As industries continue to embrace automation and digitalization, the demand for advanced switch and regulation types in air-operated pinch valves is expected to increase. This trend is likely to drive innovation in the market, leading to the development of more sophisticated and efficient valve solutions. Overall, the choice of switch type and regulation type is a crucial consideration for businesses looking to optimize their flow control systems and improve operational efficiency.

Mining Industry, Chemical Industry, Municipal Industry, Power Industry, Other Industries in the Global Air-Operated Pinch Valve Market:

The Global Air-Operated Pinch Valve Market finds extensive usage across various industries due to its unique ability to handle challenging materials and conditions. In the mining industry, these valves are essential for controlling the flow of slurries, which are mixtures of water and finely ground rock. The abrasive nature of slurries can quickly wear down traditional valves, but air-operated pinch valves, with their flexible sleeves, offer a durable solution that minimizes maintenance and downtime. In the chemical industry, air-operated pinch valves are used to manage the flow of corrosive and hazardous chemicals. Their design ensures that the chemicals do not come into contact with any metal parts, reducing the risk of corrosion and contamination. This makes them ideal for applications where maintaining the purity of the chemicals is critical. In the municipal industry, these valves are commonly used in wastewater treatment plants to control the flow of sewage and sludge. Their ability to handle thick, viscous materials without clogging makes them a reliable choice for these applications. In the power industry, air-operated pinch valves are used in various processes, including the handling of fly ash and other by-products of power generation. Their robust design allows them to withstand the harsh conditions often found in power plants. Other industries, such as food and beverage, pharmaceuticals, and pulp and paper, also benefit from the use of air-operated pinch valves. In the food and beverage industry, for example, these valves are used to control the flow of liquids and semi-solids, ensuring that the products remain uncontaminated. In the pharmaceutical industry, they are used to handle sensitive materials that require precise flow control. The versatility and reliability of air-operated pinch valves make them a valuable asset in any industry where flow control is a critical component of the production process. Their ability to handle a wide range of materials and conditions, combined with their low maintenance requirements, makes them an attractive option for businesses looking to improve efficiency and reduce costs. As industries continue to evolve and face new challenges, the demand for air-operated pinch valves is expected to grow, driving further innovation and development in the market.

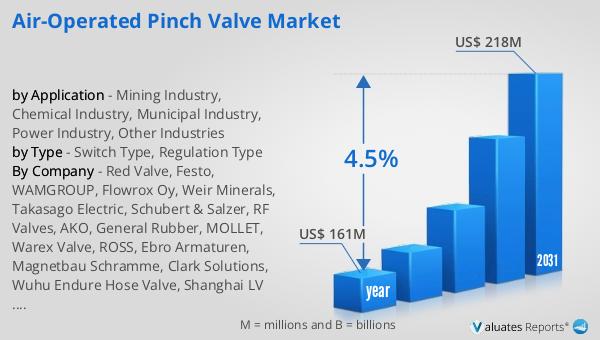

Global Air-Operated Pinch Valve Market Outlook:

The global market for air-operated pinch valves was valued at $161 million in 2024 and is anticipated to expand to a revised size of $218 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable flow control solutions across various industries. The market's expansion is driven by the need for valves that can handle abrasive, corrosive, and viscous materials without compromising performance or longevity. As industries such as mining, chemical processing, and wastewater management continue to seek ways to enhance operational efficiency and reduce maintenance costs, the adoption of air-operated pinch valves is expected to rise. These valves offer a cost-effective solution by minimizing downtime and extending the lifespan of system components. The market is characterized by a diverse range of products, with variations in size, material, and design to suit different industrial requirements. The integration of advanced technologies, such as sensors and control systems, is also playing a significant role in the evolution of the air-operated pinch valve market. These technologies enable real-time monitoring and control of valve operations, providing valuable data that can be used to optimize performance and reduce maintenance costs. As industries continue to embrace automation and digitalization, the demand for advanced air-operated pinch valves is expected to increase, driving further innovation and development in the market. Overall, the global air-operated pinch valve market is poised for steady growth, driven by the increasing demand for efficient and reliable flow control solutions across various industries.

| Report Metric | Details |

| Report Name | Air-Operated Pinch Valve Market |

| Accounted market size in year | US$ 161 million |

| Forecasted market size in 2031 | US$ 218 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Red Valve, Festo, WAMGROUP, Flowrox Oy, Weir Minerals, Takasago Electric, Schubert & Salzer, RF Valves, AKO, General Rubber, MOLLET, Warex Valve, ROSS, Ebro Armaturen, Magnetbau Schramme, Clark Solutions, Wuhu Endure Hose Valve, Shanghai LV Machine |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |