What is Global Aerospace Service Robotics Market?

The Global Aerospace Service Robotics Market is a rapidly evolving sector that focuses on the development and deployment of robotic systems designed to perform various tasks within the aerospace industry. These robotic systems are engineered to enhance efficiency, precision, and safety in aerospace operations. The market encompasses a wide range of robotic applications, including maintenance, inspection, manufacturing, and assembly processes. With advancements in technology, these robots are becoming increasingly sophisticated, capable of performing complex tasks that were once solely reliant on human intervention. The integration of robotics in aerospace not only reduces the risk of human error but also significantly cuts down on operational costs and time. As the aerospace industry continues to grow, the demand for service robotics is expected to rise, driven by the need for automation and the pursuit of higher standards in quality and safety. The market is characterized by continuous innovation, with companies investing heavily in research and development to create more advanced and versatile robotic solutions. This trend is further fueled by the increasing adoption of artificial intelligence and machine learning technologies, which are enhancing the capabilities of aerospace service robots. Overall, the Global Aerospace Service Robotics Market represents a crucial component of the modern aerospace industry, offering solutions that are essential for meeting the demands of a rapidly changing technological landscape.

Articulated, Cylindrical, Scara, Cartesian, Others in the Global Aerospace Service Robotics Market:

In the Global Aerospace Service Robotics Market, various types of robots are utilized, each serving specific functions and offering unique advantages. Articulated robots are among the most common types used in aerospace applications. These robots have rotary joints and can range from simple two-jointed structures to complex systems with ten or more interacting joints. Their flexibility and range of motion make them ideal for tasks that require precision and dexterity, such as assembly and welding. Articulated robots are particularly valued for their ability to mimic human arm movements, allowing them to perform intricate tasks with high accuracy. Cylindrical robots, on the other hand, have a primary arm that moves in a cylindrical space, offering a combination of rotary and linear motion. This design is particularly useful for tasks that require a high degree of reach and the ability to move vertically and horizontally, such as material handling and packaging. SCARA (Selective Compliance Assembly Robot Arm) robots are known for their speed and precision in horizontal movements, making them suitable for tasks like pick-and-place, assembly, and packaging. Their design allows for high-speed operations with a high degree of repeatability, which is crucial in the aerospace industry where precision is paramount. Cartesian robots, also known as gantry robots, operate on three linear axes (X, Y, and Z) and are known for their accuracy and repeatability. They are often used in applications that require precise linear movements, such as CNC machining and 3D printing. Cartesian robots are valued for their simplicity and ease of programming, making them a popular choice for tasks that require straightforward, repetitive motions. Other types of robots in the aerospace service market include spherical and parallel robots, each offering unique capabilities that cater to specific needs within the industry. Spherical robots, with their ability to rotate around a central point, are often used in applications that require a wide range of motion in a compact space. Parallel robots, known for their strength and rigidity, are used in tasks that require high-speed and high-precision operations, such as flight simulation and testing. Each type of robot plays a vital role in the aerospace service robotics market, contributing to the overall efficiency and effectiveness of aerospace operations. As technology continues to advance, these robots are expected to become even more sophisticated, offering enhanced capabilities and opening up new possibilities for automation in the aerospace industry.

Drilling & Fastening, Inspection, Welding, Painting & Coating, Others in the Global Aerospace Service Robotics Market:

The Global Aerospace Service Robotics Market finds its applications in various areas, each benefiting from the precision and efficiency that robotics bring. In drilling and fastening, robots are employed to perform tasks that require high precision and consistency. These robots are equipped with advanced sensors and control systems that allow them to drill holes and fasten components with a level of accuracy that is difficult to achieve manually. This not only improves the quality of the work but also significantly reduces the time required for these tasks. In inspection, aerospace service robots are used to perform detailed inspections of aircraft components and systems. Equipped with advanced imaging and sensing technologies, these robots can detect defects and anomalies that may not be visible to the human eye. This capability is crucial for ensuring the safety and reliability of aircraft, as it allows for the early detection and rectification of potential issues. In welding, robots are used to perform precise and consistent welds, which are essential for maintaining the structural integrity of aircraft. Robotic welding systems are capable of performing complex welds with a high degree of accuracy, reducing the risk of defects and improving the overall quality of the welds. In painting and coating, robots are used to apply paint and coatings to aircraft surfaces with precision and consistency. This not only ensures a high-quality finish but also reduces the amount of paint and coating material required, resulting in cost savings. Additionally, robotic painting systems can operate in hazardous environments, reducing the risk to human workers. Other applications of aerospace service robotics include material handling, assembly, and maintenance. In material handling, robots are used to move and position components and materials with precision and efficiency. In assembly, robots are used to assemble components and systems with a high degree of accuracy, reducing the risk of errors and improving the overall quality of the assembly. In maintenance, robots are used to perform routine maintenance tasks, such as cleaning and lubrication, with precision and efficiency. Overall, the use of robotics in these areas not only improves the efficiency and quality of aerospace operations but also enhances safety by reducing the risk of human error and exposure to hazardous environments.

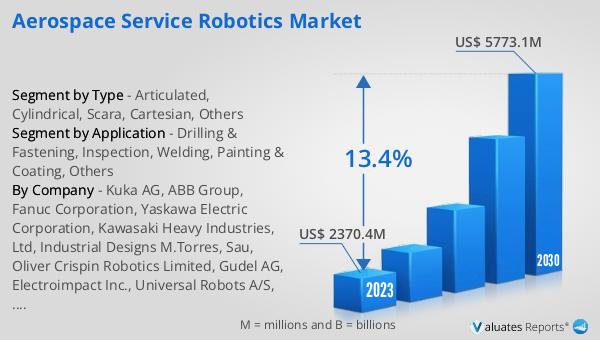

Global Aerospace Service Robotics Market Outlook:

The global market for Aerospace Service Robotics was valued at $3,041 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $7,250 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 13.4% over the forecast period. This impressive growth is driven by the increasing demand for automation and the need for enhanced efficiency and precision in aerospace operations. As the aerospace industry continues to expand, the adoption of service robotics is becoming increasingly essential to meet the demands of modern aerospace manufacturing and maintenance processes. The integration of advanced technologies such as artificial intelligence and machine learning is further enhancing the capabilities of aerospace service robots, making them more versatile and efficient. This, in turn, is driving the demand for these robots across various applications within the aerospace industry. The market is also benefiting from the growing emphasis on safety and quality in aerospace operations, as service robots are capable of performing tasks with a high degree of accuracy and consistency, reducing the risk of human error. As a result, the Global Aerospace Service Robotics Market is poised for significant growth, offering numerous opportunities for companies operating in this space to innovate and expand their offerings.

| Report Metric | Details |

| Report Name | Aerospace Service Robotics Market |

| Accounted market size in year | US$ 3041 million |

| Forecasted market size in 2031 | US$ 7250 million |

| CAGR | 13.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kuka AG, ABB Group, Fanuc Corporation, Yaskawa Electric Corporation, Kawasaki Heavy Industries, Ltd, Industrial Designs M.Torres, Sau, Oliver Crispin Robotics Limited, Gudel AG, Electroimpact Inc., Universal Robots A/S, Mitsubishi Electric, Staubli, Siasun Robot and Automation, Wolf Robotics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |