What is Global Intumescent Coating for Structural Steel Market?

The Global Intumescent Coating for Structural Steel Market is a specialized segment within the broader coatings industry, focusing on providing fire protection solutions for steel structures. Intumescent coatings are a type of passive fire protection that expands when exposed to high temperatures, forming an insulating char layer that helps to maintain the structural integrity of steel during a fire. This market is driven by the increasing demand for fire safety in construction and infrastructure projects worldwide. As urbanization and industrialization continue to rise, the need for effective fire protection in high-rise buildings, factories, and public venues becomes more critical. The market encompasses various types of intumescent coatings, including water-based and solvent-based formulations, each offering distinct advantages in terms of application, performance, and environmental impact. The growth of this market is also influenced by stringent building codes and regulations that mandate the use of fire-resistant materials in construction. As a result, manufacturers are continually innovating to develop coatings that not only meet safety standards but also offer ease of application and aesthetic appeal. The Global Intumescent Coating for Structural Steel Market is poised for steady growth as safety concerns and regulatory requirements drive demand for advanced fire protection solutions.

Water Based, Solvent Based in the Global Intumescent Coating for Structural Steel Market:

Water-based and solvent-based intumescent coatings are two primary types of formulations used in the Global Intumescent Coating for Structural Steel Market, each with unique characteristics and applications. Water-based intumescent coatings are formulated with water as the primary solvent, making them environmentally friendly and less hazardous to apply. These coatings are known for their low volatile organic compound (VOC) emissions, which contribute to better air quality and reduced health risks for applicators. Water-based coatings are often preferred in projects where environmental regulations are stringent, and sustainability is a priority. They are also easier to clean up and dispose of, reducing the overall environmental impact of the coating process. However, water-based coatings may require longer drying times and can be sensitive to humidity and temperature variations during application, which can affect their performance. On the other hand, solvent-based intumescent coatings use organic solvents as the primary carrier for the active ingredients. These coatings are known for their robust performance in harsh environments and their ability to adhere well to various substrates, including steel. Solvent-based coatings typically offer faster drying times and are less sensitive to environmental conditions during application, making them suitable for use in a wide range of climates and conditions. They are often chosen for projects where rapid application and curing are essential, such as in industrial settings or regions with unpredictable weather. However, solvent-based coatings can emit higher levels of VOCs, which may pose health risks to applicators and contribute to air pollution. As a result, their use is often subject to stricter regulatory controls, and proper safety measures must be in place during application. Both water-based and solvent-based intumescent coatings play crucial roles in the Global Intumescent Coating for Structural Steel Market, offering solutions tailored to specific project needs and regulatory requirements. The choice between the two often depends on factors such as environmental considerations, application conditions, and performance requirements. Manufacturers continue to innovate in both categories, developing advanced formulations that enhance fire protection while minimizing environmental impact. For instance, hybrid coatings that combine the benefits of both water-based and solvent-based systems are being explored to offer improved performance and sustainability. As the market evolves, the demand for coatings that balance safety, performance, and environmental responsibility is expected to drive further advancements in both water-based and solvent-based intumescent coatings.

Steel Structure Factory Building, Stadium & Exhibition Hall, High Rise Building, Other in the Global Intumescent Coating for Structural Steel Market:

The Global Intumescent Coating for Structural Steel Market finds extensive usage across various sectors, including steel structure factory buildings, stadiums and exhibition halls, high-rise buildings, and other infrastructure projects. In steel structure factory buildings, intumescent coatings are essential for ensuring the safety and longevity of the structure. These coatings provide a critical layer of fire protection, allowing the steel framework to maintain its load-bearing capacity during a fire, thereby preventing structural collapse. This is particularly important in industrial settings where the risk of fire is higher due to the presence of flammable materials and processes. By applying intumescent coatings, factory owners can enhance the safety of their facilities, protect valuable assets, and comply with fire safety regulations. In stadiums and exhibition halls, intumescent coatings play a vital role in safeguarding large public spaces where thousands of people gather. These venues often feature complex architectural designs with extensive use of steel structures, making fire protection a top priority. Intumescent coatings help to ensure that the steel framework can withstand high temperatures during a fire, providing critical time for evacuation and emergency response. The aesthetic appeal of these coatings is also important in such settings, as they must blend seamlessly with the overall design while offering robust fire protection. As a result, manufacturers offer a range of coatings that combine fire resistance with aesthetic versatility, allowing architects and designers to achieve their vision without compromising on safety. High-rise buildings represent another significant application area for intumescent coatings. As urbanization continues to drive the construction of taller and more complex structures, the need for effective fire protection becomes increasingly important. Intumescent coatings are applied to the steel framework of high-rise buildings to ensure that they can withstand the intense heat of a fire, preventing structural failure and allowing occupants to evacuate safely. These coatings are often part of a comprehensive fire protection strategy that includes active systems such as sprinklers and alarms. The use of intumescent coatings in high-rise buildings is often mandated by building codes and regulations, underscoring their importance in ensuring the safety and resilience of modern urban infrastructure. Beyond these specific applications, intumescent coatings are also used in a variety of other settings, including bridges, tunnels, and transportation infrastructure. In these contexts, the coatings provide essential fire protection for steel components exposed to harsh environmental conditions and potential fire hazards. The versatility and effectiveness of intumescent coatings make them a valuable tool in enhancing the safety and durability of steel structures across a wide range of industries. As the Global Intumescent Coating for Structural Steel Market continues to grow, the demand for innovative and high-performance coatings that meet the diverse needs of different sectors is expected to drive further advancements in this field.

Global Intumescent Coating for Structural Steel Market Outlook:

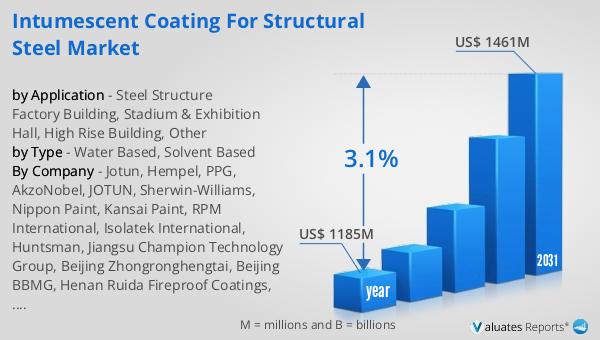

The global market for Intumescent Coating for Structural Steel was valued at $1,185 million in 2024 and is anticipated to expand to a revised size of $1,461 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% over the forecast period. This growth trajectory underscores the increasing importance of fire protection in construction and infrastructure projects worldwide. As urbanization and industrialization continue to accelerate, the demand for effective fire safety solutions in high-rise buildings, factories, and public venues is on the rise. Intumescent coatings, with their ability to provide passive fire protection by expanding and forming an insulating char layer when exposed to high temperatures, are becoming an integral part of modern construction practices. The market's expansion is also driven by stringent building codes and regulations that mandate the use of fire-resistant materials, prompting manufacturers to innovate and develop coatings that not only meet safety standards but also offer ease of application and aesthetic appeal. As a result, the Global Intumescent Coating for Structural Steel Market is poised for steady growth, with safety concerns and regulatory requirements continuing to drive demand for advanced fire protection solutions.

| Report Metric | Details |

| Report Name | Intumescent Coating for Structural Steel Market |

| Accounted market size in year | US$ 1185 million |

| Forecasted market size in 2031 | US$ 1461 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Jotun, Hempel, PPG, AkzoNobel, JOTUN, Sherwin-Williams, Nippon Paint, Kansai Paint, RPM International, Isolatek International, Huntsman, Jiangsu Champion Technology Group, Beijing Zhongronghengtai, Beijing BBMG, Henan Ruida Fireproof Coatings, Beijing Xinkun |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |