What is Global Copper Core Ball Market?

The Global Copper Core Ball Market is a specialized segment within the broader electronics and semiconductor industry. Copper core balls are tiny spheres made primarily of copper, often used in various electronic applications due to their excellent electrical conductivity and thermal properties. These balls are integral components in the manufacturing of semiconductors, serving as interconnects in devices like Ball Grid Arrays (BGAs) and Chip Scale Packages (CSPs). The demand for copper core balls is driven by the rapid advancement in electronic devices, which require reliable and efficient components to function optimally. As technology continues to evolve, the need for smaller, more efficient, and higher-performing electronic components increases, thereby boosting the demand for copper core balls. The market is characterized by continuous innovation, with manufacturers striving to produce balls with better performance characteristics, such as improved conductivity and heat resistance. This market is also influenced by the global trends in electronics manufacturing, including the shift towards miniaturization and the increasing complexity of electronic devices. As a result, the Global Copper Core Ball Market is poised for growth, driven by technological advancements and the ever-increasing demand for high-performance electronic components.

Less than 200 µm, 200-500 µm, Above 500 µm in the Global Copper Core Ball Market:

In the Global Copper Core Ball Market, the size of the copper core balls plays a crucial role in determining their application and performance. These balls are typically categorized into three size segments: less than 200 µm, 200-500 µm, and above 500 µm. Each size category serves different purposes and is selected based on the specific requirements of the electronic devices they are used in. Balls less than 200 µm are often used in applications where miniaturization is key. As electronic devices become smaller and more compact, the demand for these tiny copper core balls increases. They are particularly useful in advanced semiconductor packaging technologies where space is at a premium. The small size allows for more connections in a limited space, enhancing the performance and efficiency of the device. On the other hand, copper core balls in the 200-500 µm range are commonly used in standard semiconductor applications. This size range offers a balance between performance and ease of handling, making them suitable for a wide range of electronic devices. They provide reliable electrical connections and are often used in devices where moderate performance and cost-effectiveness are important. Lastly, copper core balls above 500 µm are used in applications where robustness and durability are critical. These larger balls are typically used in high-power applications where the components need to withstand significant electrical and thermal stress. The larger size provides better heat dissipation and mechanical strength, making them ideal for use in power electronics and other demanding applications. The choice of ball size is influenced by several factors, including the specific requirements of the electronic device, the manufacturing process, and the desired performance characteristics. As the electronics industry continues to evolve, the demand for copper core balls of various sizes is expected to grow, driven by the need for more efficient and reliable electronic components.

BGA, CSP, Other in the Global Copper Core Ball Market:

The Global Copper Core Ball Market finds its usage in various areas, including Ball Grid Arrays (BGA), Chip Scale Packages (CSP), and other applications. In BGA applications, copper core balls are used as interconnects between the semiconductor die and the printed circuit board (PCB). The use of copper core balls in BGA packages provides several advantages, including improved electrical conductivity, better thermal performance, and enhanced mechanical strength. These characteristics are crucial in ensuring the reliability and performance of the electronic device. As electronic devices become more complex and require higher performance, the demand for copper core balls in BGA applications is expected to increase. In CSP applications, copper core balls are used to create a direct connection between the semiconductor die and the PCB. CSPs are a type of semiconductor package that offers a smaller footprint and improved performance compared to traditional packaging methods. The use of copper core balls in CSPs allows for a more compact design, which is essential in modern electronic devices where space is limited. The excellent electrical and thermal properties of copper core balls make them an ideal choice for CSP applications, where performance and reliability are critical. In addition to BGA and CSP applications, copper core balls are also used in other areas, such as in the manufacturing of LEDs, sensors, and other electronic components. The versatility of copper core balls makes them suitable for a wide range of applications, where their excellent conductivity and thermal properties can be leveraged to enhance the performance of the device. As the demand for more efficient and reliable electronic components continues to grow, the usage of copper core balls in various applications is expected to increase, driven by the need for high-performance and compact electronic devices.

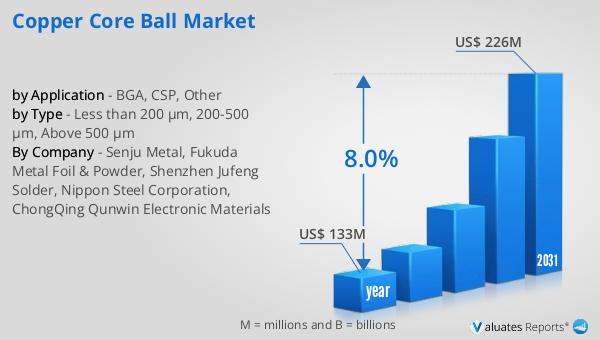

Global Copper Core Ball Market Outlook:

The global market for Copper Core Ball was valued at approximately 133 million USD in 2024. This market is anticipated to expand significantly, reaching an estimated size of 226 million USD by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.0% over the forecast period. The increasing demand for copper core balls is largely driven by the rapid advancements in electronic devices and the growing need for efficient and reliable components. As technology continues to evolve, the demand for smaller, more efficient, and higher-performing electronic components is expected to rise, thereby boosting the market for copper core balls. The market's growth is also influenced by the global trends in electronics manufacturing, including the shift towards miniaturization and the increasing complexity of electronic devices. Manufacturers in the copper core ball market are continuously innovating to produce balls with better performance characteristics, such as improved conductivity and heat resistance, to meet the evolving needs of the electronics industry. As a result, the Global Copper Core Ball Market is poised for significant growth, driven by technological advancements and the ever-increasing demand for high-performance electronic components.

| Report Metric | Details |

| Report Name | Copper Core Ball Market |

| Accounted market size in year | US$ 133 million |

| Forecasted market size in 2031 | US$ 226 million |

| CAGR | 8.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Senju Metal, Fukuda Metal Foil & Powder, Shenzhen Jufeng Solder, Nippon Steel Corporation, ChongQing Qunwin Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |