What is Global Palladium-Plated Copper Bonding Wire Market?

The Global Palladium-Plated Copper Bonding Wire Market is a specialized segment within the electronics industry, focusing on the production and distribution of bonding wires used in semiconductor devices. These wires are essential for creating electrical connections between the silicon chip and the external leads of a semiconductor device. Palladium-plated copper bonding wires are particularly valued for their excellent conductivity, corrosion resistance, and cost-effectiveness compared to traditional gold bonding wires. The palladium plating enhances the wire's performance by providing a protective layer that prevents oxidation and improves the wire's overall durability. This market is driven by the increasing demand for miniaturized and high-performance electronic devices, which require reliable and efficient bonding solutions. As technology advances, the need for more sophisticated semiconductor devices grows, further propelling the demand for palladium-plated copper bonding wires. The market is characterized by continuous innovation and development, with manufacturers striving to improve the quality and performance of their products to meet the evolving needs of the electronics industry. The global reach of this market is evident as it caters to various regions, each with its own set of requirements and standards, making it a dynamic and competitive field.

0-20 um, 20-30 um, 30-50 um, Above 50 um in the Global Palladium-Plated Copper Bonding Wire Market:

In the Global Palladium-Plated Copper Bonding Wire Market, the wire diameter plays a crucial role in determining its application and performance. The market is segmented based on wire diameters, including 0-20 µm, 20-30 µm, 30-50 µm, and above 50 µm, each serving different purposes in semiconductor manufacturing. The 0-20 µm segment is primarily used in applications requiring ultra-fine bonding wires, such as advanced microelectronics and high-density integrated circuits (ICs). These wires are essential for creating precise and reliable connections in compact devices, where space is at a premium. The 20-30 µm segment is commonly used in standard ICs and transistors, offering a balance between strength and flexibility. This diameter range is suitable for a wide range of applications, providing reliable performance in various electronic devices. The 30-50 µm segment is typically used in power devices and applications requiring higher current carrying capacity. These wires offer enhanced mechanical strength and are capable of handling more significant electrical loads, making them ideal for power electronics and automotive applications. Finally, the above 50 µm segment is used in specialized applications where robustness and durability are paramount. These wires are often employed in industrial and heavy-duty electronics, where they must withstand harsh environmental conditions and mechanical stress. Each diameter segment within the Global Palladium-Plated Copper Bonding Wire Market is tailored to meet specific industry needs, ensuring that manufacturers can provide the most suitable solutions for their customers. The choice of wire diameter is influenced by factors such as the device's design, operating conditions, and performance requirements, highlighting the importance of selecting the right bonding wire for each application. As the demand for more advanced and efficient electronic devices continues to grow, the market for palladium-plated copper bonding wires is expected to expand, with manufacturers focusing on developing innovative products to meet the evolving needs of the industry.

ICs, Transistor, Others in the Global Palladium-Plated Copper Bonding Wire Market:

The Global Palladium-Plated Copper Bonding Wire Market finds extensive usage in various areas, including integrated circuits (ICs), transistors, and other electronic components. In the realm of ICs, these bonding wires are crucial for establishing reliable connections between the silicon chip and the package leads. The use of palladium-plated copper wires in ICs offers several advantages, such as improved electrical conductivity, enhanced thermal performance, and reduced material costs compared to traditional gold wires. This makes them an attractive choice for manufacturers looking to optimize the performance and cost-effectiveness of their ICs. In transistors, palladium-plated copper bonding wires play a vital role in ensuring efficient electrical connections and heat dissipation. The superior conductivity and thermal properties of these wires contribute to the overall performance and reliability of transistors, which are essential components in various electronic devices. The use of these wires in transistors helps manufacturers achieve better energy efficiency and device longevity, making them a preferred choice in the industry. Beyond ICs and transistors, palladium-plated copper bonding wires are also used in other electronic components, such as sensors, diodes, and LEDs. These wires provide the necessary electrical connections and support the miniaturization of electronic devices, enabling the development of smaller and more efficient products. The versatility and performance benefits of palladium-plated copper bonding wires make them a valuable asset in the electronics industry, where the demand for high-performance and cost-effective solutions continues to rise. As technology advances and the need for more sophisticated electronic devices grows, the usage of palladium-plated copper bonding wires is expected to expand across various applications, driving innovation and development in the market.

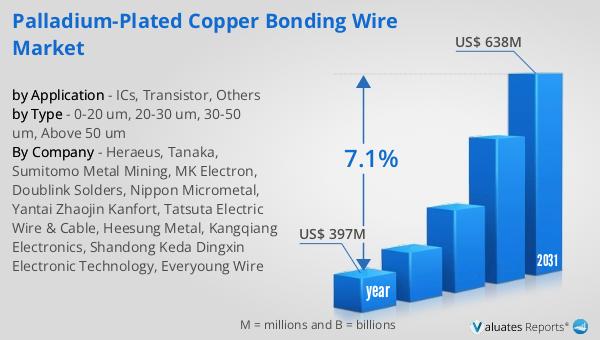

Global Palladium-Plated Copper Bonding Wire Market Outlook:

The global market for palladium-plated copper bonding wire was valued at approximately $397 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $638 million by 2031. This growth represents a compound annual growth rate (CAGR) of 7.1% over the forecast period. The increasing demand for advanced electronic devices and the need for cost-effective and reliable bonding solutions are key factors driving this market expansion. Palladium-plated copper bonding wires offer a compelling alternative to traditional gold wires, providing excellent conductivity and corrosion resistance at a lower cost. This makes them an attractive option for manufacturers looking to enhance the performance and affordability of their products. As the electronics industry continues to evolve, the demand for high-performance bonding wires is expected to rise, further fueling the growth of this market. The market's expansion is also supported by ongoing technological advancements and the development of new applications for palladium-plated copper bonding wires. Manufacturers are continually innovating to improve the quality and performance of their products, ensuring they meet the changing needs of the industry. With a strong focus on research and development, the global market for palladium-plated copper bonding wire is poised for continued growth and success in the coming years.

| Report Metric | Details |

| Report Name | Palladium-Plated Copper Bonding Wire Market |

| Accounted market size in year | US$ 397 million |

| Forecasted market size in 2031 | US$ 638 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heraeus, Tanaka, Sumitomo Metal Mining, MK Electron, Doublink Solders, Nippon Micrometal, Yantai Zhaojin Kanfort, Tatsuta Electric Wire & Cable, Heesung Metal, Kangqiang Electronics, Shandong Keda Dingxin Electronic Technology, Everyoung Wire |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |