What is Global Bridge Anticorrosive Coating Market?

The Global Bridge Anticorrosive Coating Market is a specialized segment within the broader coatings industry, focusing on protective solutions designed to prevent corrosion on bridge structures. These coatings are essential for maintaining the integrity and longevity of bridges, which are constantly exposed to harsh environmental conditions such as moisture, salt, and varying temperatures. The market encompasses a variety of coating types, each formulated to address specific challenges associated with different bridge materials and environmental exposures. The demand for these coatings is driven by the need to extend the lifespan of bridges, reduce maintenance costs, and ensure safety. As infrastructure development continues to be a priority worldwide, the market for bridge anticorrosive coatings is expected to grow, with innovations in coating technologies further enhancing their effectiveness. These coatings not only protect against rust and corrosion but also contribute to the aesthetic appeal of bridges, making them a crucial component in both new construction and the maintenance of existing structures. The market is characterized by a diverse range of products, including epoxy, polyurethane, and other specialized coatings, each offering unique benefits and applications.

Epoxy Coating, Polyurethane Coating, Others in the Global Bridge Anticorrosive Coating Market:

Epoxy coatings are a cornerstone of the Global Bridge Anticorrosive Coating Market, renowned for their excellent adhesion, durability, and resistance to chemicals and moisture. These coatings form a tough, protective layer that adheres strongly to the surface of bridge materials, providing a robust barrier against corrosive elements. Epoxy coatings are particularly effective in environments where bridges are exposed to saltwater or industrial pollutants, making them a popular choice for coastal and urban areas. Their ability to withstand harsh conditions without degrading ensures that bridges remain structurally sound over extended periods. Polyurethane coatings, on the other hand, offer a different set of advantages. Known for their flexibility and UV resistance, polyurethane coatings are ideal for bridges that experience significant temperature fluctuations and exposure to sunlight. This flexibility allows the coating to expand and contract with the bridge materials, preventing cracks and maintaining a continuous protective layer. Additionally, polyurethane coatings provide a glossy finish, enhancing the aesthetic appeal of bridges. Other types of coatings in the market include zinc-rich primers, which offer sacrificial protection by corroding in place of the underlying metal, and acrylic coatings, which are valued for their ease of application and quick drying times. Each type of coating is selected based on the specific requirements of the bridge, including its location, material, and environmental exposure. The choice of coating is critical, as it directly impacts the longevity and maintenance needs of the bridge. In recent years, advancements in coating technology have led to the development of hybrid coatings that combine the benefits of multiple types, offering enhanced protection and performance. These innovations are driving the market forward, as infrastructure projects increasingly demand coatings that can deliver superior protection while minimizing environmental impact. The Global Bridge Anticorrosive Coating Market is thus a dynamic and evolving sector, with ongoing research and development efforts aimed at creating more effective and sustainable solutions.

Arch Bridge, Beam Bridge, Cantilever Bridge, Suspension Bridge, Others in the Global Bridge Anticorrosive Coating Market:

The usage of Global Bridge Anticorrosive Coating Market products varies significantly across different types of bridges, each with its unique structural and environmental challenges. Arch bridges, known for their curved design and ability to span large distances, often require coatings that can withstand significant stress and environmental exposure. The coatings used on arch bridges must be flexible enough to accommodate the natural movement of the structure while providing robust protection against moisture and pollutants. Beam bridges, characterized by their simple, straight design, typically require coatings that offer excellent adhesion and durability. These bridges are often used in areas with heavy traffic, necessitating coatings that can withstand constant vibration and wear. Cantilever bridges, which extend horizontally and are supported at only one end, present unique challenges in terms of load distribution and environmental exposure. The coatings used on cantilever bridges must be able to protect against corrosion while accommodating the dynamic forces acting on the structure. Suspension bridges, known for their iconic design and ability to span great distances, require coatings that can withstand extreme environmental conditions, including high winds and saltwater exposure. The coatings used on suspension bridges must be highly durable and resistant to UV radiation, ensuring long-term protection and minimal maintenance. Other types of bridges, such as cable-stayed and truss bridges, also benefit from specialized anticorrosive coatings that address their specific structural and environmental needs. In all cases, the choice of coating is critical to ensuring the safety, longevity, and aesthetic appeal of the bridge. The Global Bridge Anticorrosive Coating Market plays a vital role in providing the solutions needed to protect these essential infrastructure components, contributing to the overall safety and efficiency of transportation networks worldwide.

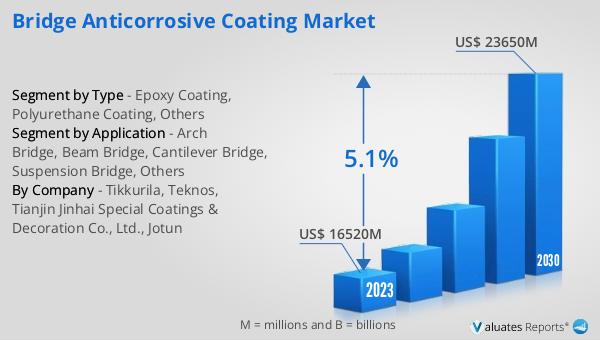

Global Bridge Anticorrosive Coating Market Outlook:

In 2024, the global market for Bridge Anticorrosive Coating was valued at approximately US$ 18,350 million. This market is anticipated to expand significantly, reaching an estimated size of US$ 25,870 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.1% over the forecast period. The increasing demand for durable and effective anticorrosive coatings is driven by the need to protect vital infrastructure from the damaging effects of corrosion, which can lead to costly repairs and safety hazards. As countries around the world continue to invest in infrastructure development and maintenance, the demand for high-quality anticorrosive coatings is expected to rise. This growth is further supported by advancements in coating technologies, which are enhancing the performance and sustainability of these products. The market's expansion reflects the critical role that anticorrosive coatings play in ensuring the longevity and safety of bridges, which are essential components of transportation networks. As the market continues to evolve, it is likely to see increased innovation and competition, driving further improvements in product quality and environmental performance.

| Report Metric | Details |

| Report Name | Bridge Anticorrosive Coating Market |

| Accounted market size in year | US$ 18350 million |

| Forecasted market size in 2031 | US$ 25870 million |

| CAGR | 5.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tikkurila, Teknos, Tianjin Jinhai Special Coatings & Decoration Co., Ltd., Jotun |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |