What is Global Over 500 mm UHP Graphite Electrode Market?

The Global Over 500 mm UHP Graphite Electrode Market refers to the international market for ultra-high power (UHP) graphite electrodes that are over 500 millimeters in diameter. These electrodes are essential components in electric arc furnaces (EAFs), which are used in steelmaking and other metallurgical processes. UHP graphite electrodes are known for their ability to withstand extremely high temperatures and conduct electricity efficiently, making them ideal for use in EAFs where intense heat is required to melt scrap metal and other raw materials. The market for these electrodes is driven by the demand for steel and other metals, as well as advancements in EAF technology that require larger and more efficient electrodes. As industries continue to seek more sustainable and cost-effective methods of production, the demand for UHP graphite electrodes is expected to grow, particularly in regions with significant steel production activities. The market is characterized by a few key players who dominate the production and supply of these specialized electrodes, and it is influenced by factors such as raw material availability, technological advancements, and global economic conditions.

500 mm UHP Graphite Electrode, 550 mm UHP Graphite Electrode, 600 mm UHP Graphite Electrode, 650 mm UHP Graphite Electrode, 700 mm UHP Graphite Electrode, over 700 mm UHP Graphite Electrode in the Global Over 500 mm UHP Graphite Electrode Market:

The 500 mm UHP Graphite Electrode is a critical component in the steelmaking industry, particularly in electric arc furnaces (EAFs). These electrodes are designed to handle the high electrical currents and extreme temperatures required to melt scrap metal and other raw materials. The 500 mm size is often used in smaller EAFs or in applications where space is limited but high performance is still necessary. Moving up in size, the 550 mm UHP Graphite Electrode offers increased surface area and conductivity, making it suitable for medium-sized EAFs that require a balance between efficiency and cost. The 600 mm UHP Graphite Electrode is a popular choice for larger EAFs, providing enhanced performance and durability. These electrodes are capable of handling higher electrical loads, which translates to faster melting times and increased productivity. The 650 mm UHP Graphite Electrode is designed for even larger EAFs, offering superior conductivity and thermal resistance. This size is often used in high-capacity steelmaking operations where efficiency and output are critical. The 700 mm UHP Graphite Electrode represents one of the largest standard sizes available, providing maximum conductivity and thermal performance. These electrodes are used in the largest EAFs, where they contribute to significant energy savings and reduced production times. Finally, the over 700 mm UHP Graphite Electrode is a specialized product designed for the most demanding applications. These electrodes are custom-made to meet the specific needs of ultra-large EAFs, offering unparalleled performance and efficiency. Each size of UHP graphite electrode plays a vital role in the global steelmaking industry, with manufacturers continually seeking to improve their products to meet the evolving demands of the market. The choice of electrode size depends on various factors, including the size of the EAF, the type of steel being produced, and the specific requirements of the production process. As the global demand for steel continues to rise, the market for over 500 mm UHP graphite electrodes is expected to grow, driven by the need for more efficient and sustainable production methods.

Electric Arc Furnace Steel, Other (Phosphorus, Silicon, etc.) in the Global Over 500 mm UHP Graphite Electrode Market:

The Global Over 500 mm UHP Graphite Electrode Market plays a crucial role in the production of steel using electric arc furnaces (EAFs). EAFs are a popular choice for steelmaking due to their flexibility, efficiency, and lower environmental impact compared to traditional blast furnaces. UHP graphite electrodes are essential components in EAFs, as they conduct the high electrical currents needed to generate the intense heat required to melt scrap metal and other raw materials. The use of over 500 mm UHP graphite electrodes in EAFs allows for increased efficiency and productivity, as larger electrodes can handle higher electrical loads and provide better thermal performance. This results in faster melting times, reduced energy consumption, and lower production costs. In addition to steelmaking, UHP graphite electrodes are also used in other metallurgical processes, such as the production of phosphorus and silicon. These processes require high temperatures and precise control, making UHP graphite electrodes an ideal choice due to their excellent conductivity and thermal resistance. The demand for UHP graphite electrodes in these applications is driven by the growing need for high-quality phosphorus and silicon products, which are used in a wide range of industries, including electronics, chemicals, and agriculture. As industries continue to seek more sustainable and cost-effective production methods, the use of UHP graphite electrodes is expected to increase, particularly in regions with significant steel and metallurgical production activities. The market for over 500 mm UHP graphite electrodes is characterized by a few key players who dominate the production and supply of these specialized products. These manufacturers are continually investing in research and development to improve the performance and efficiency of their electrodes, as well as to expand their product offerings to meet the evolving needs of the market. Factors such as raw material availability, technological advancements, and global economic conditions also influence the market, as they impact the cost and availability of UHP graphite electrodes. Overall, the Global Over 500 mm UHP Graphite Electrode Market is a dynamic and growing industry, driven by the increasing demand for steel and other metallurgical products, as well as the need for more efficient and sustainable production methods.

Global Over 500 mm UHP Graphite Electrode Market Outlook:

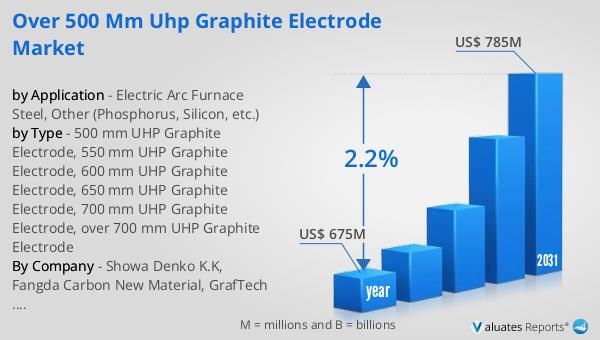

In 2024, the global market for Over 500 mm UHP Graphite Electrode was valued at approximately $675 million. This market is anticipated to grow steadily, reaching an estimated size of $785 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.2% over the forecast period. The steady increase in market size reflects the rising demand for UHP graphite electrodes, driven by the expanding steel production industry and the need for more efficient and sustainable manufacturing processes. As industries continue to evolve and seek ways to reduce their environmental impact, the demand for high-performance UHP graphite electrodes is expected to grow. This market growth is also supported by advancements in electric arc furnace technology, which require larger and more efficient electrodes to meet the increasing demands of steel production. The market is characterized by a few key players who dominate the production and supply of these specialized electrodes, and it is influenced by factors such as raw material availability, technological advancements, and global economic conditions. As the market continues to expand, manufacturers are investing in research and development to improve the performance and efficiency of their products, as well as to expand their product offerings to meet the evolving needs of the market.

| Report Metric | Details |

| Report Name | Over 500 mm UHP Graphite Electrode Market |

| Accounted market size in year | US$ 675 million |

| Forecasted market size in 2031 | US$ 785 million |

| CAGR | 2.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Showa Denko K.K, Fangda Carbon New Material, GrafTech International, Graphite India Limited (GIL), HEG Limited, Tokai Carbon, SEC Carbon, Ltd, Energoprom Group, Jilin Carbon, Kaifeng Carbon, Nantong Yangzi Carbon, Sanergy Group Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |