What is Vapor Blast Cabinet - Global Market?

A vapor blast cabinet is a specialized piece of equipment used in various industries for surface treatment and cleaning applications. It operates by using a mixture of water and abrasive media to clean, polish, or finish surfaces. This process is often referred to as wet blasting or liquid honing. The global market for vapor blast cabinets is driven by their efficiency and effectiveness in achieving a smooth, clean surface without damaging the underlying material. These cabinets are widely used in industries such as automotive, aerospace, and manufacturing, where precision and surface integrity are crucial. The demand for vapor blast cabinets is increasing due to their ability to handle delicate components and provide a superior finish compared to traditional dry blasting methods. Additionally, the environmental benefits of using water as a dust suppressant make vapor blast cabinets an attractive option for companies looking to reduce their environmental footprint. As industries continue to seek advanced surface treatment solutions, the vapor blast cabinet market is expected to grow, driven by technological advancements and the need for high-quality surface finishes.

Portable, For Trailer, Blast Cabinet in the Vapor Blast Cabinet - Global Market:

Portable vapor blast cabinets designed for trailers are a versatile and convenient solution for on-site surface treatment needs. These units are specifically engineered to be mobile, allowing them to be transported easily to different locations, making them ideal for industries that require flexibility and mobility in their operations. The portability of these cabinets does not compromise their performance; they are equipped with powerful blasting capabilities that can handle a wide range of materials and surface conditions. The trailer-mounted design ensures that the equipment can be set up quickly and efficiently, reducing downtime and increasing productivity. This is particularly beneficial for industries such as construction, shipbuilding, and maintenance services, where on-site surface preparation and cleaning are essential. The global market for portable vapor blast cabinets is expanding as more companies recognize the advantages of having a mobile solution that can be deployed wherever needed. These cabinets are designed to withstand harsh environments and are built with durable materials to ensure longevity and reliability. The ease of use and maintenance of portable vapor blast cabinets also contribute to their growing popularity. Operators can quickly learn to use the equipment, and routine maintenance is straightforward, ensuring that the cabinets remain in optimal working condition. The versatility of portable vapor blast cabinets extends to the types of surfaces they can treat. They are effective on metals, plastics, composites, and other materials, making them suitable for a wide range of applications. Whether it's removing paint, rust, or scale, or preparing a surface for coating, these cabinets deliver consistent and high-quality results. The ability to adjust the blasting parameters allows operators to tailor the process to the specific requirements of each job, ensuring that the desired surface finish is achieved. In addition to their performance capabilities, portable vapor blast cabinets offer environmental benefits. The use of water in the blasting process reduces dust and airborne contaminants, creating a safer working environment for operators and reducing the impact on surrounding areas. This is particularly important in industries where environmental regulations are stringent, and companies are looking for ways to minimize their environmental footprint. The global market for portable vapor blast cabinets is also influenced by technological advancements. Manufacturers are continuously developing new features and enhancements to improve the efficiency and effectiveness of these units. Innovations such as automated controls, improved abrasive media delivery systems, and enhanced safety features are making portable vapor blast cabinets more attractive to a wider range of industries. As the demand for high-quality surface treatment solutions continues to grow, the market for portable vapor blast cabinets is expected to expand, driven by the need for flexible, efficient, and environmentally friendly equipment.

Surface Preparation, Degreasing, Cleaning of Dies and Moulds, Removal of Paint, Rust, Scale, Others in the Vapor Blast Cabinet - Global Market:

Vapor blast cabinets are widely used in various industries for surface preparation, degreasing, cleaning of dies and molds, removal of paint, rust, scale, and other applications. In surface preparation, vapor blast cabinets provide a smooth and clean surface that is essential for subsequent coating or finishing processes. The wet blasting process ensures that the surface is free from contaminants and imperfections, resulting in a high-quality finish. This is particularly important in industries such as automotive and aerospace, where surface integrity is crucial for the performance and longevity of components. In degreasing applications, vapor blast cabinets effectively remove oils, grease, and other contaminants from surfaces, ensuring that they are clean and ready for further processing. The combination of water and abrasive media in the blasting process breaks down and removes stubborn residues, leaving the surface clean and free from contaminants. This is essential in industries where cleanliness is critical, such as food processing and pharmaceuticals. The cleaning of dies and molds is another important application of vapor blast cabinets. These components often accumulate residues and build-up during production processes, which can affect their performance and the quality of the products they produce. Vapor blast cabinets provide an efficient and effective solution for cleaning dies and molds, ensuring that they are free from residues and ready for use. The gentle nature of the wet blasting process ensures that the surfaces of dies and molds are not damaged, preserving their integrity and extending their lifespan. The removal of paint, rust, and scale is a common application for vapor blast cabinets. These cabinets are highly effective at removing coatings and corrosion from surfaces, restoring them to their original condition. The wet blasting process ensures that the underlying material is not damaged, making it an ideal solution for delicate components and surfaces. This is particularly important in industries such as restoration and maintenance, where preserving the integrity of the original material is essential. In addition to these applications, vapor blast cabinets are used for a variety of other purposes, including surface finishing, polishing, and deburring. The versatility of these cabinets makes them suitable for a wide range of industries and applications, providing a high-quality finish and improving the performance and longevity of components. As industries continue to seek advanced surface treatment solutions, the demand for vapor blast cabinets is expected to grow, driven by their effectiveness, efficiency, and environmental benefits.

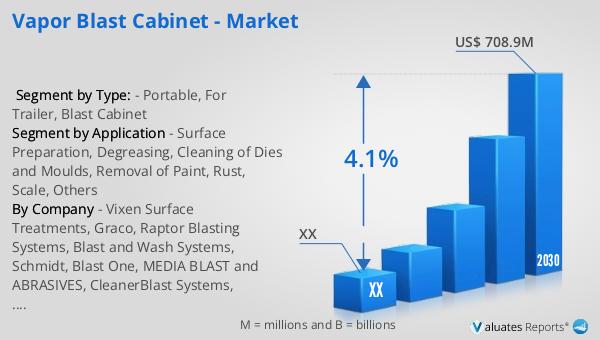

Vapor Blast Cabinet - Global Market Outlook:

The global market for vapor blast cabinets was valued at approximately $539 million in 2023. It is projected to grow to a revised size of around $708.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced surface treatment solutions across various industries. The North American market for vapor blast cabinets also shows promising growth potential, although specific figures for this region were not provided. The anticipated growth in the North American market is expected to align with the global trend, driven by technological advancements and the need for high-quality surface finishes. The market outlook suggests that as industries continue to prioritize efficiency, precision, and environmental sustainability, the demand for vapor blast cabinets will continue to rise. This growth is further supported by the increasing adoption of vapor blast cabinets in industries such as automotive, aerospace, and manufacturing, where surface integrity and quality are paramount. As companies seek to enhance their production processes and reduce their environmental impact, vapor blast cabinets offer a viable solution that meets these needs. The market's expansion is also likely to be fueled by ongoing innovations and improvements in vapor blast cabinet technology, making them more efficient, user-friendly, and environmentally friendly.

| Report Metric | Details |

| Report Name | Vapor Blast Cabinet - Market |

| Forecasted market size in 2030 | US$ 708.9 million |

| CAGR | 4.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Vixen Surface Treatments, Graco, Raptor Blasting Systems, Blast and Wash Systems, Schmidt, Blast One, MEDIA BLAST and ABRASIVES, CleanerBlast Systems, YUGONG MACHINERY, KAFAN MACHINERY and EQUIPMENT |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |