What is Secondary Spill Containment - Global Market?

Secondary spill containment refers to systems and structures designed to prevent the release of hazardous substances into the environment in the event of a primary containment failure. This market is crucial for industries that handle potentially dangerous materials, such as chemicals, oil, and waste products. The global market for secondary spill containment is driven by stringent environmental regulations and the increasing awareness of the need to protect ecosystems from contamination. These systems include spill pallets, berms, and containment tanks, which are used to capture leaks and spills, preventing them from reaching the ground or water sources. The market is characterized by a diverse range of products tailored to different industrial needs, ensuring that companies can comply with environmental standards while maintaining operational efficiency. As industries continue to expand and environmental concerns grow, the demand for effective secondary spill containment solutions is expected to rise, making it a vital component of industrial safety and environmental protection strategies worldwide.

PVC, TPU, LLDPE, Others in the Secondary Spill Containment - Global Market:

Secondary spill containment systems are made from various materials, each offering unique benefits and applications. PVC, or polyvinyl chloride, is a common material used in secondary spill containment due to its durability and resistance to chemicals. It is often used in the construction of spill berms and liners, providing a reliable barrier against leaks. PVC is also cost-effective, making it a popular choice for industries looking to implement spill containment solutions without incurring high expenses. TPU, or thermoplastic polyurethane, is another material used in secondary spill containment. It is known for its flexibility and strength, making it ideal for applications that require a high degree of adaptability. TPU is resistant to abrasion and punctures, which enhances its durability in harsh industrial environments. This material is often used in the production of flexible containment systems, such as collapsible tanks and portable berms, which can be easily deployed and stored. LLDPE, or linear low-density polyethylene, is a material that offers excellent chemical resistance and impact strength. It is commonly used in the manufacturing of spill pallets and containment trays, providing a robust solution for capturing leaks and spills. LLDPE is also lightweight, which makes it easy to handle and install, further enhancing its appeal in the secondary spill containment market. Other materials used in secondary spill containment include metals and composites, which offer additional strength and durability for specific applications. These materials are often used in the construction of permanent containment structures, such as bunds and dikes, which provide long-term protection against spills. The choice of material for secondary spill containment depends on various factors, including the type of substance being contained, the environmental conditions, and the specific requirements of the industry. Each material offers distinct advantages, allowing companies to select the most appropriate solution for their needs. As the demand for secondary spill containment continues to grow, manufacturers are investing in research and development to create innovative materials that offer enhanced performance and sustainability. This focus on material innovation is expected to drive the evolution of the secondary spill containment market, providing industries with more effective and environmentally friendly solutions.

Transport Vehicles and Containers, Machinery & Equipment, Others in the Secondary Spill Containment - Global Market:

Secondary spill containment systems are essential in various applications, including transport vehicles and containers, machinery and equipment, and other areas. In transport vehicles and containers, secondary spill containment is crucial for preventing leaks and spills during the transportation of hazardous materials. These systems are designed to capture any accidental releases, ensuring that they do not contaminate the environment or pose a risk to public safety. Spill containment pallets and liners are commonly used in transport vehicles to provide an additional layer of protection against leaks. These solutions are particularly important for industries that transport chemicals, oil, and other hazardous substances, as they help to minimize the risk of environmental damage and regulatory penalties. In machinery and equipment, secondary spill containment systems are used to capture leaks and spills that may occur during operation or maintenance. These systems are designed to contain any accidental releases, preventing them from reaching the ground or water sources. Spill trays and drip pans are commonly used in machinery and equipment to provide a reliable solution for capturing leaks. These systems are essential for industries that operate heavy machinery, such as manufacturing and construction, as they help to maintain a safe and clean working environment. In other areas, secondary spill containment systems are used to provide protection against leaks and spills in various industrial applications. These systems are designed to capture any accidental releases, ensuring that they do not contaminate the environment or pose a risk to public safety. Spill berms and containment tanks are commonly used in these applications to provide a robust solution for capturing leaks. These systems are particularly important for industries that handle large volumes of hazardous materials, as they help to minimize the risk of environmental damage and regulatory penalties. Overall, secondary spill containment systems play a vital role in protecting the environment and ensuring the safety of workers and the public. As industries continue to expand and environmental concerns grow, the demand for effective secondary spill containment solutions is expected to rise, making it a crucial component of industrial safety and environmental protection strategies worldwide.

Secondary Spill Containment - Global Market Outlook:

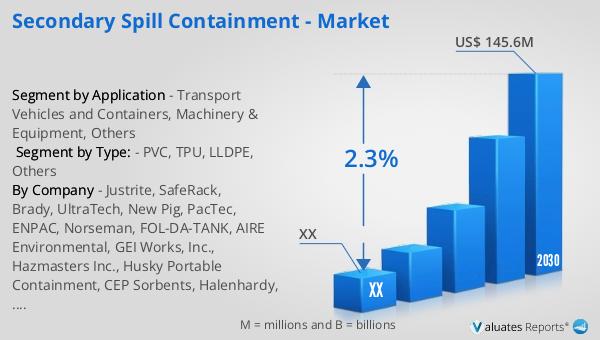

The global market for secondary spill containment was valued at approximately $124.7 million in 2023. It is projected to grow to an estimated $145.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. This growth is driven by increasing environmental regulations and the need for industries to comply with safety standards to prevent hazardous spills. The North American market for secondary spill containment is also expected to see significant growth during this period. Although specific figures for the North American market were not provided, it is anticipated to follow a similar upward trend, driven by stringent environmental policies and the presence of major industries requiring spill containment solutions. The market's expansion is supported by technological advancements and the development of innovative materials that enhance the effectiveness and efficiency of spill containment systems. As industries become more aware of the environmental impact of spills and the associated costs of non-compliance, the demand for reliable and cost-effective secondary spill containment solutions is expected to increase. This growth presents opportunities for manufacturers and suppliers to develop and offer advanced products that meet the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Secondary Spill Containment - Market |

| Forecasted market size in 2030 | US$ 145.6 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Justrite, SafeRack, Brady, UltraTech, New Pig, PacTec, ENPAC, Norseman, FOL-DA-TANK, AIRE Environmental, GEI Works, Inc., Hazmasters Inc., Husky Portable Containment, CEP Sorbents, Halenhardy, LLC, EnviroZone, LLC, Meltblown Technologies, LLC, EnSafeCo LLC, Versatech Products Inc., Absorbent Products Ltd., EnviroGuard |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |